Hot Melt Adhesive

Hot melt adhesives exist in solid form and are classified by different types of raw materials. Polyurethane (Polyurethane Hot Melt Adhesive) is a reactive type of hot melt adhesive for the base material. After cooling, there will be a chemical cross-linking reaction. Rubber-based pressure-sensitive hot melt adhesives are mainly used in packaging, labels ,metal back stickers and so on.

Reactive types of hot melt adhesives can bond a variety of substrates, including some difficult-to-bond plastics. These adhesives can handle all walks of life’s toughest bonding applications. The hot melt adhesives is the best choose of high-speed processing, bonding diversity, large gap filling, rapid initial strength and less shrinkage.

DeepMaterial reactive types of hot melt adhesives have many advantages: the open time ranges from seconds to minutes, did’t need the fixtures, long-term durability and excellent moisture resistance, chemical resistance, oil resistance and temperature resistance. DeepMaterial’s reactive types of hot melt adhesive products are solvent-free.

DeepMaterial Main Advantages of Hot Melt Adhesive

Advantages of hot melt adhesive:

· High production efficiency (shorter curing time)

· Easy to realize the automate the process

· Combines adhesive and sealant properties

Advantages of pressure sensitive hot melt adhesive:

· Long-lasting stickiness

· Self-adhesive coating

· Coating and assembly can be separated

Advantages of reactive polyurethane hot melt adhesive:

· Low application temperature

· Long opening hours

· Quick curing

Temperature Resistance

Hot melt adhesives of different systems have different temperature resistance ranges.

Bonding Different Substrates

Different systems of hot melt adhesives have different adhesion to polar or non-polar substrates, and are suitable for bonding different substrates. Such as various plastics, metal and wood and paper.

Chemical Resistance

Different systems of hot melt adhesives have different resistance to chemical media.

Bonding Strength

Thermoplastic hot melt adhesives can gain ultimate strength immediately after cooling. They soften again when the temperature rises. Moisture-curing polyurethane hot-melt adhesive exists in thermosetting form after absorbing moisture and cross-linking, and the cured polyurethane hot-melt adhesive cannot be melted anymore.

Hot Melt Adhesive Product Selection

| Product Series | Product Name | Application Characteristics |

| Reactive

hot-melt adhesive | DM-6515 | A reactive polyurethane hot melt adhesive for blind hole of LCD screen. This product has high thixotropy and high OD value, fast reaction speed, high initial strength, and rapid curing process can greatly improve production line effiffifficiency. |

| DM-6516 | A reactive polyurethane hot melt adhesive for blind hole of LCD screen. This product has high thixotropy and high OD value, fast reaction speed, high initial strength, and rapid curing process can greatly improve production line effiffifficiency. | |

| Double-curing

UV adhesive

| DM-6595 | A reactive polyurethane hot melt adhesive is used for edge sealing and shading of LCD. The product has fast reaction speed and high initial strength, and is suitable for high-speed automatic assembly line operation. |

| DM-6597 | A reactive polyurethane hot melt adhesive is used for edge sealing and shading of LCD. The product has fast reaction speed and high initial strength, and is suitable for high-speed automatic assembly line operation. | |

| Reactive hot

melt adhesive

| DM-6601 | A UV/moisture double-curing black blackout adhesive with an OD value of more than 2.5. The 3s rapid curing process can greatly improve the effiffifficiency of the production line. |

| DM-6602 | A UV/moisture double-curing black blackout adhesive with an OD value of more than 2.5. The 3s rapid curing process can greatly improve the effiffifficiency of the production line. | |

| DM-6520 | A one-component moisture curing reactive polyurethane hot-melt adhesive, which is heated for several minutes to be used after melting. After cooling for several minutes at room temperature, it has good initial bonding strength, extremely short opening time, and has the advantages of excellent elongation, rapid assembly, and environmental friendliness. | |

| DM-6524 | A one-component moisture curing reactive polyurethane hot-melt adhesive, which is heated for several minutes to be used after melting. After cooling for several minutes at room temperature, it has good initial bonding strength, extremely short opening time, and has the advantages of excellent elongation, rapid assembly, and environmental friendliness. | |

| DM-6575 | A one-component moisture curing reactive polyurethane hot-melt adhesive, which is heated for several minutes to be used after melting. After cooling for several minutes at room temperature, it has good initial bonding strength, extremely short opening time, and has the advantages of excellent elongation, rapid assembly, and environmental friendliness. | |

| DM-6521 | A one-component moisture curing reactive polyurethane hot-melt adhesive, which is heated for several minutes to be used after melting. After cooling for several minutes at room temperature, it has good initial bonding strength, extremely short opening time, and has the advantages of excellent elongation, rapid assembly, and environmental friendliness. |

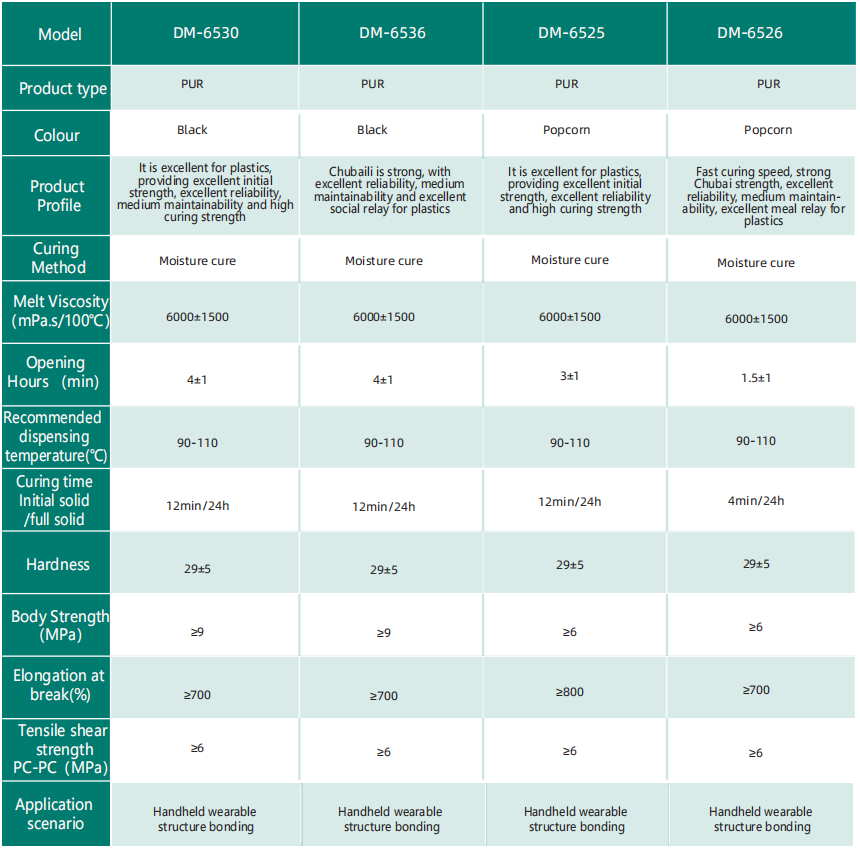

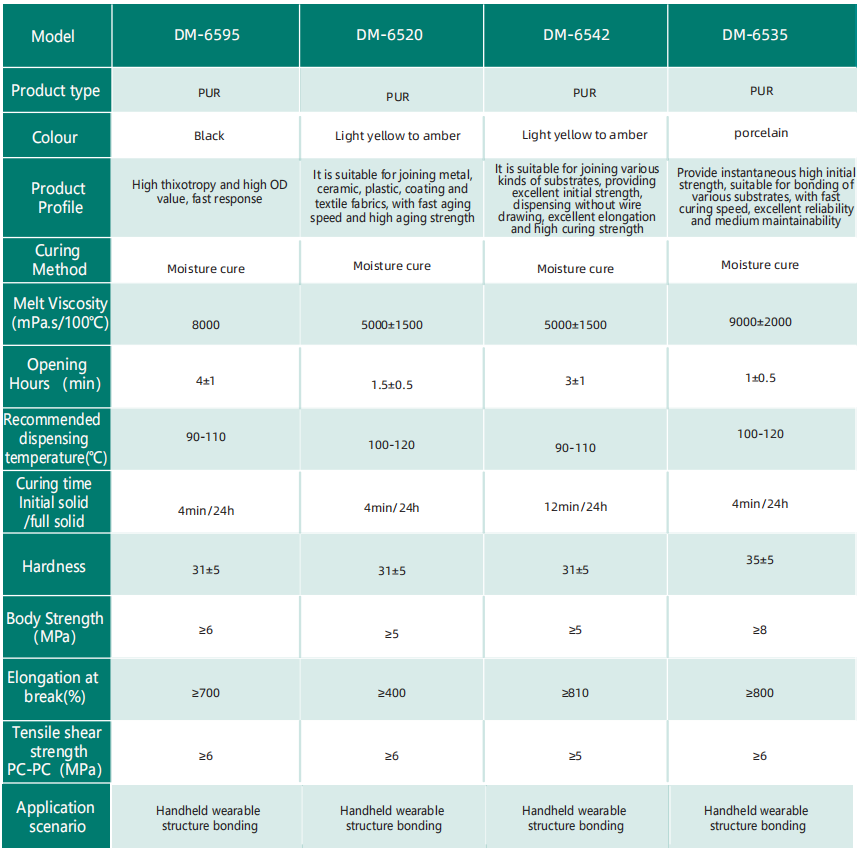

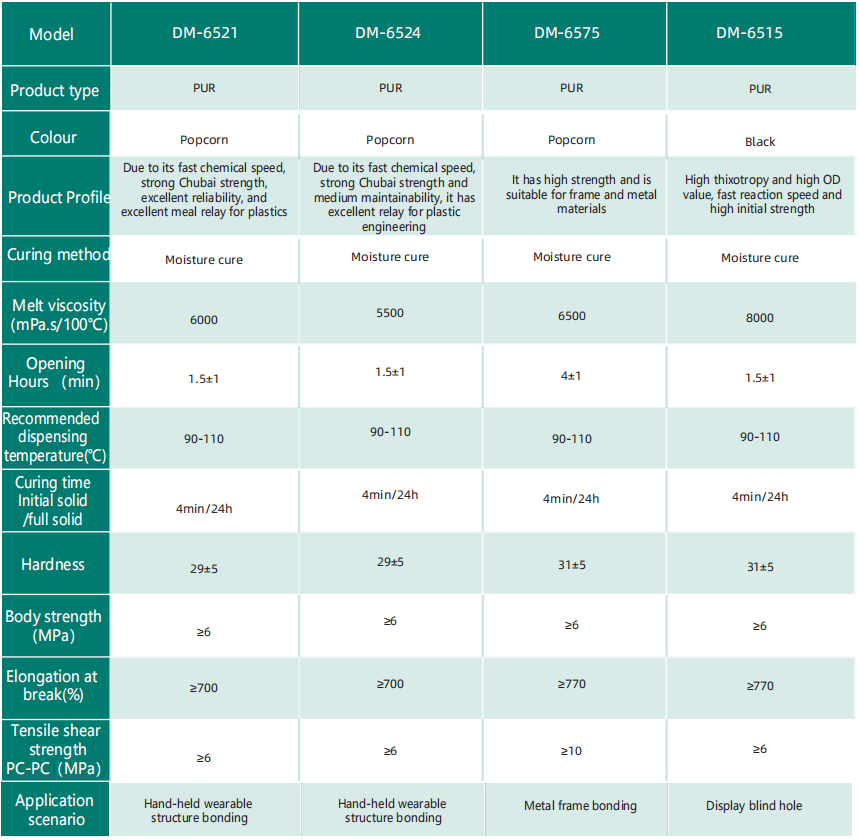

Hot Melt Adhesive Product Data Sheet