- Home

- >

- Application

- >

- Smartphone Adhesive

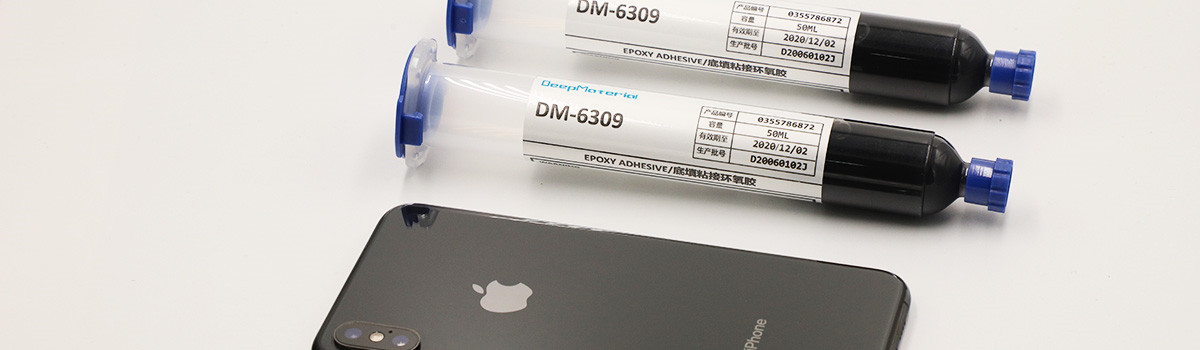

Smartphone Adhesive

Smartphone Adhesive is where innovation meets technology to ensure your mobile devices’ seamless functionality and durability. In this category, we explore the various aspects of smartphone adhesives, shedding light on their importance, types, and applications in the ever-evolving world of mobile technology.

Table of Contents

ToggleWhat is Smartphone Adhesive, and Why is it Crucial?

Smartphone adhesive refers to the adhesive or glue used to assemble smartphones to bond various components. These adhesives play a crucial role in the structural integrity and functionality of the device. Here are some reasons why smartphone adhesive is vital:

Assembly and Bonding:

- Smartphones have numerous components, such as the display, battery, camera modules, circuit boards, and more. The adhesive is used to bond these components securely during the assembly process.

Structural Integrity:

- The adhesive helps create a solid and rigid structure for the smartphone. This is important to ensure that the device can withstand the stresses and strains of everyday use, such as drops and impacts.

Water Resistance:

- Some smartphones are designed to be water-resistant or waterproof. Adhesive plays a crucial role in creating seals and barriers that prevent water from entering the internal components, protecting the device from water damage.

Vibration Dampening:

- Smartphones can be vibrated by the user tapping on the screen or the device being in motion. Adhesive helps dampen these vibrations, preventing components from becoming loose or damaged over time.

Thermal Management:

- Adhesives with thermal conductivity properties are often used to facilitate heat dissipation from the internal components, such as the processor and battery. This helps prevent overheating and ensures the proper functioning of the device.

Slim Design:

- With the trend towards smaller and more compact smartphones, manufacturers need adhesives that provide strong bonding without adding unnecessary bulk to the device.

Ease of Repair:

- In cases where smartphones need to be repaired or components replaced, the adhesive used can affect the ease of disassembly and reassembly. Some adhesives are designed to be easily removable without causing damage to the components.

Screen Bonding:

- Adhesives are crucial for bonding the display to the rest of the device. This is particularly important for touchscreen devices, as a strong bond ensures proper touch sensitivity and display functionality.

smartphone adhesive is a critical component in manufacturing, contributing to overall durability, water resistance, thermal management, and device functionality. Manufacturers carefully select and apply adhesives to meet each smartphone model’s specific design and performance requirements.

How Does Adhesive Contribute to the Structural Integrity of Smartphones?

Adhesives play a crucial role in the structural integrity of smartphones by providing bonding and support for various components. Here are several ways in which adhesives contribute to the structural integrity of smartphones:

Component Bonding:

- Adhesives are used to bond different components together within the smartphone’s assembly. This includes attaching the display to the frame, securing the battery, and connecting various internal parts such as circuit boards, sensors, and connectors.

Waterproofing and Dust Resistance:

- Adhesives are often used to create seals that help make smartphones resistant to water and dust. These seals are applied around the device’s edges, preventing moisture and particles from entering and potentially damaging internal components.

Shock Absorption:

- Adhesives with shock-absorbing properties can be strategically placed to absorb and dissipate mechanical shocks. This helps protect the internal components from damage caused by drops or impacts.

Flexibility and Durability:

- Adhesives can enhance the flexibility and durability of specific components, such as flexible displays. They help maintain the structural integrity of these components while allowing for the necessary flexibility in design.

Thermal Management:

- Some adhesives are designed to have thermal conductivity properties. By applying these adhesives strategically, heat generated by the smartphone’s internal components can be efficiently transferred and dissipated, preventing overheating and potential damage.

Slim Design and Lightweight Construction:

- Adhesives contribute to smartphones’ overall thin and lightweight design by eliminating the need for bulky mechanical fasteners. This allows for a more compact and aesthetically pleasing device without compromising structural integrity.

Vibration Dampening:

- Adhesives can help dampen vibrations within the device, reducing the risk of components becoming loose or detached due to constant movement or mechanical stress.

Assembly Efficiency:

- Adhesives provide an efficient means of assembling smartphones during the manufacturing process. They allow for precise component positioning, enable assembly line automation, and reduce the need for complex mechanical joining methods.

Adhesives contribute significantly to the structural integrity of smartphones by providing strong bonds between components, enhancing durability, enabling flexible design, and offering protection against environmental factors such as water and dust. The use of adhesives in smartphone construction is critical in achieving the desired balance between form, function, and reliability.

Are There Different Types of Smartphone Adhesives?

Yes, smartphones have different types of adhesives, each serving specific purposes in the device’s construction and assembly. The choice of adhesive depends on factors such as the materials being bonded, the desired strength of the bond, and the intended application. Here are some common types of adhesives used in smartphones:

- Double-sided adhesive tapes:These tapes often contain a thin layer of adhesive on both sides and are commonly used for bonding components within the phone, such as attaching the battery to the device’s frame or securing small components like camera modules.

- Liquid adhesives:Liquid adhesives, such as cyanoacrylate (super glue) or epoxy, are used in various smartphone assembly processes. They can provide strong bonds and are often used to secure components requiring precise and controlled adhesive application.

- Structural adhesives:These adhesives are designed to provide structural strength and are commonly used to construct the phone’s frame or chassis. They help ensure the overall integrity and durability of the device.

- Thermal adhesives:Some smartphones use thermal adhesives to improve heat dissipation. These adhesives are designed to conduct heat away from specific components, helping to prevent overheating.

- Pressure-sensitive adhesives (PSAs):PSAs attach protective films, screen protectors, or other surface-related applications. These adhesives are typically applied as sheets and adhere to light-pressure surfaces.

- UV-curing adhesives cure quickly when exposed to ultraviolet (UV) light. They are often used when rapid bonding is required, and precise control over the curing process is essential.

Manufacturers may use a combination of these adhesives throughout the assembly process to achieve the desired results regarding strength, flexibility, and other properties. Additionally, advancements in materials science and manufacturing processes may lead to the development of new smartphone adhesive technologies.

What Role Does Adhesive Play in Smartphone Water Resistance?

Adhesive plays a crucial role in the water resistance of smartphones by sealing various components and creating a barrier against water intrusion. Smartphones are intricate devices with numerous openings, such as ports, buttons, speakers, and microphones. These openings create potential entry points for water, dust, and other foreign particles.

To prevent water from entering and damaging the internal components of a smartphone, manufacturers use adhesive materials to seal these vulnerable areas. Here are some key ways in which adhesive contributes to smartphone water resistance:

- Sealing Openings:Adhesive is applied around openings like charging ports, headphone jacks, and SIM card trays. This helps create a tight seal, preventing water from entering through these access points.

- Bonding Components:Adhesive is used to bond different smartphone components together. Creating a secure bond helps prevent water from seeping into the internal circuitry or sensitive electronic parts.

- Protecting Internals:Adhesive is applied to the device’s internal components, such as the circuit boards, to protect them from water damage. It acts as a barrier that prevents water from reaching and causing harm to the electronic elements.

- Maintaining Structural Integrity:In addition to water resistance, adhesive helps preserve the structural integrity of the smartphone. It keeps the internal components in place and ensures that the device remains durable and resistant to external elements.

- Preventing Corrosion:Water can lead to corrosion of metal components on the circuit board. Adhesive helps create a barrier that reduces the risk of water contact, minimizing the chances of corrosion and subsequent damage.

Manufacturers often use specialized adhesives designed to withstand various environmental conditions, including exposure to water. These adhesives are chosen for their durability, flexibility, and resistance to degradation over time.

It’s important to note that while adhesive is a crucial factor in making smartphones water-resistant, other design elements such as gaskets, seals, and water-resistant coatings on electronic components also contribute to overall water resistance. Smartphone manufacturers often conduct rigorous testing to ensure that their devices meet specific water resistance standards, such as IP67 or IP68 ratings, indicating the protection level against dust and water.

How Do Manufacturers Choose the Right Adhesive for Specific Models?

Manufacturers choose adhesives for specific models based on a combination of crucial factors for the intended application, production process, and bonded materials. Here are key considerations in selecting the suitable adhesive:

Substrate Compatibility:

- Adhesives must be compatible with the materials they are connecting. Different materials have varying surface energies and chemical compositions, so the adhesive should adhere well to all substrates involved in the assembly.

Environmental Conditions:

- Manufacturers consider the operating environment of the final product. Factors such as temperature, humidity, and exposure to chemicals can impact the performance of adhesives. Some adhesives are designed to withstand extreme conditions, while others may degrade or lose strength in harsh environments.

Curing Mechanism:

- Adhesives can be categorized based on their curing mechanisms, such as chemical reactions, heat, light, or moisture. The production process and the time available for curing can influence the choice of adhesive. Some adhesives cure quickly, allowing for faster production cycles.

Bond Strength Requirements:

- The strength of the bond needed for a particular application is a critical factor. Some applications require high tensile or shear strength, while others may prioritize flexibility or peel strength. Manufacturers need to match the adhesive properties to the specific load and stress conditions the bond will face.

Assembly Process:

- The manufacturing process itself plays a role in adhesive selection. Some adhesives are conducive to automated application methods, while others may require manual application or specific curing conditions that must align with the production line.

Regulatory Compliance:

- Depending on the industry and application, there may be specific regulations and standards that adhesives must meet. Manufacturers must ensure that the chosen adhesive complies with these requirements, especially in automotive, aerospace, or medical devices.

Cost Considerations:

- Cost is always a factor in manufacturing decisions. While high-performance adhesives may offer superior properties, they might also be more expensive. Manufacturers need to balance performance requirements with cost constraints to maintain competitiveness.

Testing and Validation:

- Before implementing an adhesive in mass production, manufacturers typically conduct extensive testing and validation to ensure that the adhesive meets the required specifications. This may include testing under simulated environmental conditions and assessing long-term durability.

Supplier Relationship:

- Manufacturers often develop long-term relationships with adhesive suppliers. Consistency in the quality of the adhesive is essential for maintaining the integrity of the final product, and a reliable supplier can contribute to the overall success of the manufacturing process.

By carefully considering these factors, manufacturers can choose the most suitable adhesive for their specific models, ensuring that the bonds meet performance requirements and withstand actual use conditions.

Can Smartphone Adhesives Affect Screen Clarity and Touch Sensitivity?

The adhesives used in smartphones are primarily designed to bond the various layers of the device together, including the glass or plastic screen, digitizer, and other components. Well-designed smartphones generally use adhesives with minimal impact on-screen clarity and touch sensitivity. However, there are a few considerations:

Quality of Adhesive:

- High-quality adhesives are engineered to be transparent and have minimal impact on the clarity of the display.

- Manufacturers usually select adhesives that do not interfere with the screen’s touch sensitivity.

Application Process:

- The way the adhesive is applied during the manufacturing process is crucial. Precise application ensures that no air bubbles or uneven layers could affect the display quality.

Thickness of Adhesive:

- The thickness of the adhesive layer is an essential factor. Thicker adhesives may impact touch sensitivity, so manufacturers aim to use thin yet effective adhesives.

Curing Time:

- The curing time of the adhesive is also essential. If the adhesive doesn’t fully cure, it might affect the overall performance of the touchscreen.

Manufacturer’s Quality Control:

- Reputable smartphone manufacturers typically have strict quality control measures to ensure that the adhesives and other components meet specific standards.

Repair and Replacement:

- If a smartphone undergoes repair or replacement of its screen, the quality of the adhesive used during the repair can vary. Poorly applied adhesives or the use of low-quality replacements can impact the screen.

While most smartphones are designed to maintain screen clarity and touch sensitivity, it’s worth noting that the quality can vary between different manufacturers and models. Additionally, using a smartphone in extreme conditions (such as very high or low temperatures) could affect the performance of adhesives and other components. Generally, following manufacturer guidelines for usage and care can help maintain optimal performance.

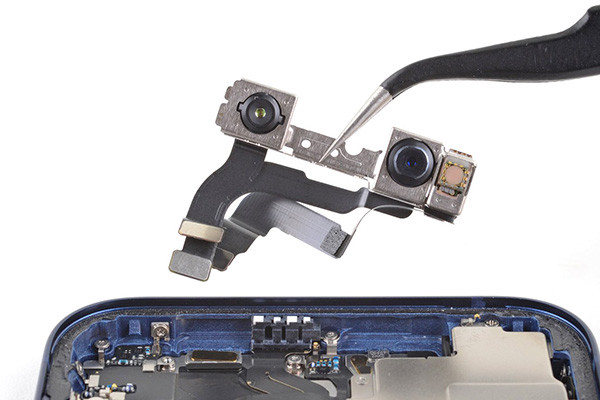

Is Adhesive Usage Different for Foldable or Flexible Display Smartphones?

Foldable and flexible display smartphones often involve different technologies and designs than traditional rigid displays. While adhesive usage is still a crucial aspect of smartphone assembly, there are some differences regarding foldable or flexible displays.

- Flexibility and Durability: Foldable and flexible displays require materials that endure repeated bending and flexing. Adhesives used in these devices must be flexible and resilient to withstand the mechanical stress associated with bending. Manufacturers use special adhesives that can maintain their properties even under constant flexing without degrading or causing display issues.

- Foldable Hinge Mechanism: Foldable smartphones typically have a hinge mechanism that allows the device to fold and unfold. Adhesives play a critical role in securing and protecting these hinges. Special adhesives are often used to ensure a strong bond that can withstand the constant folding and unfolding motion without compromising the structural integrity of the device.

- Thickness and Weight Considerations: Adhesive thickness is a crucial factor in the design of foldable and flexible displays. Manufacturers aim to keep the device as thin and lightweight as possible, so adhesives with minimal thickness and weight are preferred. This requires a careful selection of materials to balance the need for structural integrity with the desire for a sleek and lightweight device.

- Heat Dissipation: Flexible displays can sometimes generate more heat than traditional rigid displays, especially during prolonged use or demanding tasks. Adhesives used in these devices may need to contribute to effective heat dissipation to prevent overheating issues.

- Compatibility with Display Technology: Foldable and flexible displays may use different technologies, such as OLED or AMOLED. Adhesives must be compatible with these display types to ensure proper bonding without affecting the display’s functionality or image quality.

While adhesives are a fundamental part of smartphone assembly regardless of the display type, foldable and flexible displays introduce additional challenges. The adhesives must be chosen and applied carefully to accommodate these innovative display technologies’ unique mechanical stresses, flexibility requirements, and design considerations. Manufacturers often work closely with adhesive suppliers to develop and optimize adhesive solutions tailored to the specific needs of foldable and flexible smartphones.

What Innovations are Emerging in Smartphone Adhesive Technologies?

However, specific innovations and developments may have occurred since then.

- UV-Curable Adhesives:UV-curable adhesives are gaining popularity in smartphone manufacturing due to their fast curing times and muscular bond strength. These adhesives use ultraviolet light to initiate a chemical reaction that quickly solidifies the adhesive, reducing production time.

- Flexible Adhesives for Foldable Displays:With the emergence of foldable smartphones, there is a demand for adhesives that can maintain flexibility and durability under repeated bending. Manufacturers are exploring new formulations and materials to meet the unique requirements of foldable displays.

- Thermal Conductive Adhesives:As smartphones pack more powerful components into smaller spaces, managing heat becomes crucial. Thermal conductive adhesives are designed to provide both adhesion and efficient heat dissipation, improving devices’ overall performance and longevity.

- Environmentally Friendly Adhesives:The smartphone industry has a growing emphasis on sustainable and eco-friendly adhesive solutions. Manufacturers are exploring bio-based adhesives and those with reduced environmental impact to align with global sustainability goals.

- Nanotechnology in Adhesives:Nanotechnology is employed to enhance adhesives’ properties. Nano-sized particles can improve adhesion strength, conductivity, and other desirable characteristics. This technology is being researched and applied to various components in smartphones.

- Pressure-Sensitive Adhesives (PSA):PSA technology is evolving to provide stronger bonds while maintaining easy application and removal. This is particularly important for components like screen protectors and cases that users may frequently attach and detach.

- Hybrid Adhesive Systems:Some manufacturers are exploring hybrid adhesive systems that combine the benefits of multiple adhesive types. For example, a single adhesive may provide mechanical solid adhesion and efficient thermal conductivity.

- Adhesives for Advanced Materials:With advanced materials like ceramic and glass in smartphone construction, adhesives are being developed to bond these materials effectively. Ensuring compatibility with a wide range of materials is a focus for adhesive innovation.

It’s essential to check the latest sources and industry reports for the most up-to-date information on emerging innovations in smartphone adhesive technologies, as the field is dynamic and continually evolving.

How Does Temperature Affect the Performance of Smartphone Adhesives?

Temperature can significantly impact the performance of smartphone adhesives, particularly those used in the assembly and construction of electronic devices. The adhesives used in smartphones are typically designed to provide robust and durable bonds while accommodating the various stresses and conditions the device may encounter. Here are some ways in which temperature can affect the performance of smartphone adhesives:

- Viscosity Changes:Temperature can influence the viscosity of adhesives. At higher temperatures, adhesives become more liquid and less viscous, making them easier to apply. However, this can also lead to issues such as dripping or uneven application. Conversely, adhesives may become more solid and easier to work with at lower temperatures.

- Curing Time:Many adhesives undergo a curing or hardening process after application. Temperature can affect the rate at which this curing takes place. Higher temperatures generally accelerate the curing process, while lower temperatures can slow it down. Proper curing is crucial for achieving the desired bond strength.

- Bond Strength:Temperature variations can affect adhesives’ bond strength. Extreme heat can cause adhesives to soften, potentially compromising the integrity of the bond. On the other hand, frigid temperatures may make adhesives more brittle, leading to reduced flexibility and impact resistance.

- Thermal Expansion and Contraction:Smartphones are exposed to various temperatures during everyday use. The materials in the device, including adhesives, may undergo thermal expansion and contraction. Adhesives that can withstand these temperature-related dimensional changes are crucial to maintaining the structural integrity of the device.

- Performance at Extremes:Smartphones are often used in various environmental conditions, from hot climates to cold winters. Adhesives must be able to perform reliably across this broad temperature spectrum. Adhesives specifically formulated for a wide temperature range are essential to ensure the device’s functionality under diverse conditions.

- Electrical Conductivity:Some adhesives are used in electronic components and must maintain their electrical properties across temperature variations. Extreme temperatures can affect the conductivity of certain adhesives, potentially impacting the performance of electronic parts.

Manufacturers of smartphones and electronic devices typically test their products under various environmental conditions to ensure that adhesives and other materials perform optimally. Understanding the temperature-related properties of adhesives is crucial in designing and producing electronic devices that meet quality and reliability standards.

Are There Environmentally Friendly Alternatives to Traditional Adhesives?

Temperature can significantly influence the performance of smartphone adhesives in various ways. Here are some key factors to consider:

Viscosity and Application:

- High Temperatures:Increased temperature can cause adhesives to become more liquid and less viscous. This can make them easier to apply but may also lead to challenges such as dripping or uneven distribution during application.

- Low Temperatures:Conversely, colder temperatures can make adhesives more dense and more complicated to work with. It may be challenging to achieve a uniform application, and the adhesive might spread less effectively.

Curing Time:

- High Temperatures:Elevated temperatures can accelerate the curing or hardening process of adhesives. While this can speed up production processes, ensuring the adhesive cures uniformly is essential to maintain consistent bond strength.

- Low Temperatures:Colder temperatures can slow the curing process, requiring longer waiting times before the adhesive reaches its optimal strength. This can be a consideration in manufacturing processes with strict time constraints.

Bond Strength:

- High Temperatures:Excessive heat can soften adhesives, potentially reducing the overall bond strength. This softening may compromise the structural integrity of the smartphone components.

- Low Temperatures:Extremely low temperatures can make adhesives more brittle, potentially reducing flexibility and impact resistance. This can be critical when the smartphone faces mechanical stress or impacts.

Thermal Expansion and Contraction:

- Smartphones are exposed to a wide range of temperatures during everyday use. Adhesives must be capable of accommodating thermal expansion and contraction to prevent delamination or mechanical failure.

Performance at Extremes:

- Smartphone adhesives must function effectively across a broad temperature range, considering the diverse climates and environments where smartphones are used. Adhesives formulated to perform well in extreme temperatures contribute to the device’s overall reliability.

Electrical Conductivity:

- Some adhesives are used in electronic components, and their electrical properties may be temperature-sensitive. Extreme temperatures can impact the electrical conductivity of these adhesives, potentially affecting the performance of electronic elements in the smartphone.

manufacturers carefully consider the temperature sensitivity of adhesives used in smartphones to ensure the devices perform reliably in various environmental conditions. This involves selecting adhesives with appropriate properties, conducting thorough testing, and optimizing manufacturing processes for temperature-related factors.

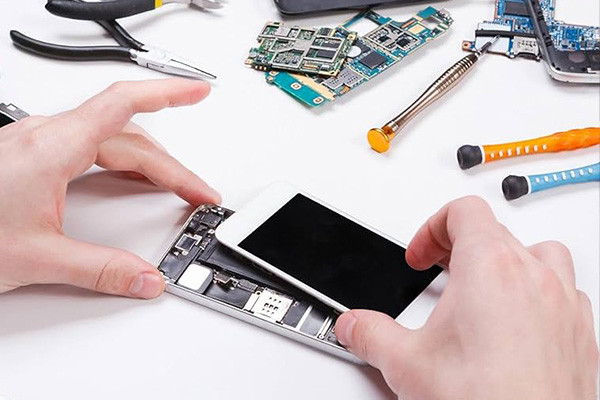

Can Users Repair or Replace Smartphone Adhesives at Home?

Repairing or replacing smartphone adhesives at home can be challenging and may only be recommended for some. Smartphone adhesives bond various components, such as the screen, battery, and other internal components. Here are some considerations:

*Specialized Adhesives:Smartphones typically use specialized adhesives for specific purposes, such as securing screens or batteries. These adhesives are often custom-designed and require particular properties to ensure proper functioning and longevity.

*Precision and Skill:Smartphone repairs require precision and skill. Replacing adhesives may involve disassembling the device, which can be complex and lead to further damage if not done correctly. Minor, delicate components may be easily damaged during the process.

*Warranty Concerns:Attempting to repair a smartphone at home may void the manufacturer’s warranty. If the device is still under warranty, repairs must be performed by authorized service providers.

*Availability of Parts:Obtaining the exact adhesive used by the manufacturer can be challenging for the average consumer. Using an incorrect adhesive may compromise the integrity of the device.

*Professional Repairs:If the smartphone is under warranty or you need clarification on performing the repair yourself, it’s advisable to seek professional help. Authorized service centers or technicians experienced in smartphone repairs are better equipped to handle these tasks.

If you’re determined to attempt a repair, it’s crucial to follow detailed guides or videos specific to your device, use the right tools, and exercise caution. However, remember that some repairs, especially adhesive ones, may be best left to professionals to ensure the device’s proper functioning and longevity.

Do Different Smartphone Brands Use Different Adhesive Technologies?

Different smartphone brands may use other adhesive technologies to manufacture their devices. Adhesives play a crucial role in assembling various smartphone components, such as attaching the display, securing the battery, connecting internal circuitry, and bonding the chassis.

The specific adhesive technologies used can vary based on factors such as the design, materials, and manufacturing processes chosen by each smartphone manufacturer. Some standard adhesive technologies include:

- Double-sided tape:This is a simple and widely used adhesive method. It’s often used to secure components like batteries and display panels.

- Liquid adhesive:Some manufacturers use liquid adhesives that are applied in a controlled manner during the assembly process. These adhesives can be cured through various methods, such as heat or ultraviolet (UV) light.

- Pressure-sensitive adhesives (PSA)are applied in sheets or films and require pressure to form a bond. PSA is commonly used in applications with a solid yet removable bond.

- Thermal adhesives:These adhesives are designed to conduct heat away from components. They are often used when efficient heat dissipation is crucial, such as attaching heat sinks to processors.

- Structural adhesives:In some cases, manufacturers may use structural adhesives that provide robust and durable bonds. These adhesives are designed to withstand stress and provide additional structural integrity to the device.

The choice of adhesive technology depends on factors like the materials used in the device, the desired strength of the bond, assembly processes, and manufacturing costs. Different smartphone manufacturers may adopt different combinations of these adhesive technologies based on their preferences and requirements for each specific model. It’s worth noting that specific details about the adhesive technologies used by a particular smartphone brand are often proprietary and may not be publicly disclosed by the manufacturers.

How Does Adhesive Impact the Wireless Charging Capability of Smartphones?

The impact of adhesive on the wireless charging capability of smartphones depends on the specific adhesive used and how it affects the transmission of electromagnetic fields between the wireless charger and the smartphone.

Wireless charging typically relies on electromagnetic induction or resonance to transfer energy from the charging pad to the smartphone. There should be minimal interference between the charging pad and the device for this process to work efficiently. Adhesives, especially those that contain metal components, can interfere with the wireless charging process.

Here are a few considerations regarding the impact of adhesive on wireless charging:

Metal Content in Adhesive:

- Some adhesives may contain metal particles or components that can obstruct the transmission of electromagnetic fields. These metal components can absorb or reflect the energy intended for the smartphone, leading to reduced charging efficiency.

Thickness and Composition:

- The thickness and composition of the adhesive layer can also influence wireless charging. If the adhesive coating is too thick or has properties that impede the transmission of electromagnetic waves, it may hinder the charging process.

Positioning and Alignment:

- Proper alignment of the smartphone on the charging pad is crucial for efficient charging. Adhesive materials that affect the alignment or create uneven surfaces may interfere with the optimal positioning of the device, resulting in slower charging or charging failure.

Heat Generation:

- Some adhesives may generate heat during the curing process or due to the wireless charging. Excessive heat can negatively impact the performance of the charging pad and the smartphone’s battery. It’s essential to choose adhesives with thermal properties compatible with wireless charging.

Compatibility Testing:

- Smartphone manufacturers often conduct compatibility testing with various adhesives to ensure the wireless charging function is not compromised. Using adhesives that have been tested and approved for wireless charging applications is advisable.

While certain adhesives may potentially impact wireless charging, it’s essential to consider the specific properties of the adhesive and how they may interfere with electromagnetic fields. Smartphone manufacturers typically consider these factors during the design and testing phases to ensure that wireless charging functionality is not compromised. If you are using third-party accessories or modifying your device, it’s crucial to choose materials known to be compatible with wireless charging technology.

Are There Safety Concerns Related to Smartphone Adhesives?

Smartphone manufacturers typically use adhesives to bond various components and secure the display. These adhesives are generally designed to meet safety standards and regulations.

However, it’s important to note that manufacturers’ materials and adhesives used in electronic devices vary. Some concerns have been raised about the potential release of harmful substances during manufacturing or in the event of device damage, such as exposure to heat or fire. For example, certain adhesives may contain volatile organic compounds (VOCs), and exposure to high temperatures could lead to the release of these compounds.

To ensure the safety of smartphone adhesives, manufacturers are expected to comply with relevant regulations and standards established by consumer safety organizations and government agencies. Additionally, consumers should follow the device manufacturers’ proper handling and care instructions to minimize potential risks.

What Challenges Do Manufacturers Face in Developing Advanced Adhesives?

Manufacturers face several challenges in developing advanced adhesives as they strive to create products with improved performance, versatility, and environmental sustainability. Some of the key challenges include:

Bonding Diverse Materials:

- Many industries require adhesives that effectively bond diverse materials, such as plastics, metals, composites, and ceramics. Developing adhesives that exhibit strong and durable bonds across a wide range of substrates can be challenging.

Performance Under Extreme Conditions:

- Adhesives are often used in applications that must withstand extreme conditions, such as high temperatures, humidity, or chemical exposure. Developing adhesives with consistent performance under such conditions is a significant challenge.

Cure Time and Processing Speed:

- Manufacturers aim to create adhesives that have a fast curing time without compromising the strength of the bond. Balancing the need for quick processing with achieving optimal adhesive performance can be a complex task.

Environmental Impact and Sustainability:

- There is an increasing emphasis on developing environmentally friendly and sustainable adhesives. This includes reducing toxic ingredients, minimizing waste, and creating adhesives with a lower carbon footprint.

Regulatory Compliance:

- Adhesive manufacturers must navigate a complex landscape of regulations and standards related to health, safety, and environmental impact. Ensuring adhesives comply with regional and global rules can be challenging.

Cost Considerations:

- Balancing the need for advanced adhesive performance with cost considerations is crucial for manufacturers. Developing cost-effective formulations without sacrificing quality can be a delicate balance.

Adhesion to Low-Energy Surfaces:

- Some materials, such as low-energy surfaces like polyethylene and polypropylene, pose challenges for adhesion. Creating adhesives that can effectively bond to these surfaces without additional surface treatments is an ongoing challenge.

Durability and Long-Term Stability:

- Adhesives are often expected to provide long-term stability and durability. Ensuring that adhesives can withstand the effects of aging, environmental exposure, and mechanical stress over an extended period is a critical consideration.

Application-Specific Requirements:

- Different industries have unique requirements for adhesives based on their specific applications. Tailoring adhesive formulations to meet the particular needs of industries such as automotive, aerospace, electronics, and medical devices can be demanding.

Innovation and Research:

- Continuous innovation is essential to stay ahead in the development of advanced adhesives. Keeping up with the latest technologies, materials, and manufacturing processes requires ongoing research and development efforts.

Addressing these challenges requires collaboration between material scientists, chemists, engineers, and other experts to develop adhesive solutions that meet the evolving demands of various industries.

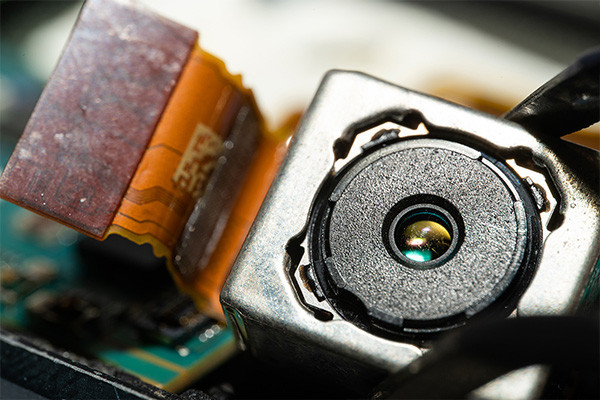

Does Adhesive Play a Role in Enhancing the Durability of Smartphone Cameras?

Adhesive does play a role in enhancing the durability of smartphone cameras, but it is just one of many factors. Smartphone cameras are complex systems that include various components, such as lenses, image sensors, and other electronic elements. Adhesives are used in the assembly process to bond these components together and to secure them within the camera module.

Here are some ways in which adhesive contributes to the durability of smartphone cameras:

- Vibration and Shock Resistance:Adhesive helps in securing the delicate components of the camera module, preventing them from getting dislodged due to vibrations or shocks. This is particularly important in a device like a smartphone that may be subject to drops and impacts.

- Environmental Protection:Adhesives can provide a barrier against environmental factors like dust, moisture, and other contaminants. This helps in protecting the sensitive electronic components of the camera from damage caused by exposure to the elements.

- Alignment and Precision:Adhesives are used in the precise assembly of camera components, ensuring that they are aligned correctly. Proper alignment is crucial for the optimal functioning of the camera, and adhesive plays a role in achieving and maintaining this alignment.

- Heat Dissipation:Some adhesives are designed to have thermal conductivity properties, helping in the efficient dissipation of heat generated by the camera components during operation. This is important for preventing overheating, which can affect the performance and lifespan of the camera.

It’s important to note that while adhesive contributes to durability, other factors such as the quality of materials, design, manufacturing processes, and overall build quality of the smartphone also play significant roles. Manufacturers typically use a combination of materials and techniques to ensure the durability and reliability of smartphone cameras. Additionally, advancements in materials science and manufacturing technologies continue to influence the design and durability of smartphone components.

How Long Does Smartphone Adhesive Typically Last?

The lifespan of smartphone adhesive can vary based on several factors, including the quality of the adhesive used, the environmental conditions to which the smartphone is exposed, and the overall build quality of the device. Smartphone manufacturers typically use adhesives that are designed to last for the expected lifespan of the device, which is typically around two to five years for most users.

Here are some considerations regarding the lifespan of smartphone adhesive:

- Quality of Adhesive:High-quality adhesives are designed to be durable and reliable over an extended period. Manufacturers often select adhesives that can withstand the stresses and environmental conditions that smartphones may encounter during regular use.

- Environmental Factors:Exposure to extreme temperatures, humidity, or other harsh environmental conditions can impact the longevity of adhesives. For instance, excessive heat can cause adhesives to degrade over time. However, smartphones are generally designed to operate within specified temperature and humidity ranges to minimize these effects.

- Build Quality:The overall build quality of the smartphone, including the design and assembly processes, can influence how well the adhesive holds up over time. A well-constructed device with precise assembly is more likely to maintain its structural integrity and adhesive bonds.

- User Handling:The way users handle their smartphones can also affect the lifespan of adhesives. Dropping the phone, applying excessive force, or subjecting it to physical stress can potentially impact the adhesive’s effectiveness.

It’s essential to note that, over several years, any adhesive may experience some degree of degradation. However, smartphone manufacturers aim to use materials and adhesives that provide reliable performance throughout the typical lifespan of the device.

If a smartphone is subjected to unusual stress, damage, or environmental conditions, it may impact the adhesive and overall device durability. In such cases, users might experience issues like components becoming dislodged or reduced resistance to water and dust. If you have concerns about the adhesive or durability of your smartphone, it’s advisable to follow the manufacturer’s guidelines for proper use and care and seek assistance from the manufacturer or authorized service centers if needed.

Are There DIY Solutions for Fixing Adhesive Issues in Smartphones?

Fixing adhesive issues in smartphones can be challenging, and it’s important to note that attempting DIY solutions may void the warranty or further damage the device if not done correctly. However, if you are comfortable with electronics and have some experience, here are some general tips that might help with some adhesive-related issues:

- Reapplying Adhesive:

- If a component, such as a battery or a back cover, is not sticking correctly, you may attempt to reapply the adhesive. However, it’s crucial to use the appropriate adhesive for the specific component, as different parts may require different types of adhesives.

- Battery Adhesive:

- Some smartphones use adhesive strips or pads to secure the battery in place. If the battery is loose, consider obtaining replacement adhesive strips designed for your specific model. Follow guides or videos for your particular device to ensure proper application.

- Repair Kits:

- There are adhesive repair kits available that include specific adhesives for smartphone components. These kits often come with detailed instructions. Make sure to purchase a kit that is compatible with your smartphone model.

- Heating to Reactivate Adhesive:

- In some cases, carefully heating the adhesive can make it more pliable. For instance, using a hair dryer on a low setting to warm the area before attempting to reattach a component might help. Be cautious not to overheat the device.

- Consult Manufacturer or Professional Repair:

- If you are unsure or uncomfortable attempting a DIY solution, it’s recommended to contact the smartphone manufacturer or seek assistance from a professional repair service. Authorized service centers have the expertise and tools needed for proper repairs.

Before attempting any DIY solution, it’s essential to research and understand the specific adhesive requirements for your smartphone model. Remember that smartphones are complex devices, and improper handling during repair attempts can lead to further damage.

If your smartphone is still under warranty, consider contacting the manufacturer or an authorized service center for advice and potential repair options. If the contract has expired, you should explore professional repair services to ensure a safe and effective solution to adhesive-related issues.

How Has Adhesive Technology Evolved Over the Years in the Smartphone Industry?

Adhesive technology in the smartphone industry has evolved significantly over the years, driven by the need for improved device durability, miniaturization, and advancements in materials science. Here are some key ways in which adhesive technology has evolved:

Nano-Adhesives and Microencapsulation:

- Manufacturers have started using nano-adhesives, tiny adhesive particles, to achieve more robust and precise bonds. Microencapsulation involves embedding adhesive materials into small capsules, allowing for controlled release and improved bonding in specific conditions.

Thermal Conductive Adhesives:

- As smartphones have become more powerful, managing heat has become a critical concern. Thermal conductive adhesives are designed to efficiently transfer heat away from components, helping to prevent overheating. This is particularly important for components like processors and cameras.

Flexible Adhesives for Foldable Devices:

- With the introduction of foldable smartphones, there’s a need for adhesives that can withstand repeated bending without losing their adhesive properties. Flexible adhesives play a crucial role in ensuring the structural integrity of foldable devices.

Waterproof and Dustproof Adhesives:

- Modern smartphones often come with water and dust resistance. Adhesives are vital in sealing the device and preventing water and particles from entering. Waterproof adhesives have improved to provide a reliable barrier against environmental elements.

UV-Curing Adhesives:

- UV-curing adhesives have gained popularity due to their ability to bond quickly when exposed to ultraviolet light. This allows for faster manufacturing processes and can contribute to increased production efficiency.

Environmentally Friendly Adhesives:

- There is a growing emphasis on environmentally friendly materials in the electronics industry, including adhesives. Manufacturers are exploring adhesives with reduced environmental impact in production, use, and disposal.

Precision Application Techniques:

- Advancements in manufacturing processes have led to more precise application techniques for adhesives. This precision is crucial in assembling small, intricate smartphone components, ensuring accurate alignment and bonding.

Improved Adhesive Testing and Quality Control:

- Quality control measures and testing methods for adhesives have improved, ensuring manufacturers can consistently produce high-quality devices with reliable adhesive bonds.

Adhesives for Wireless Charging Components:

- As wireless charging becomes more common in smartphones, the adhesives used to assemble charging components must be compatible with the technology and provide adequate insulation and bonding.

The evolution of adhesive technology is closely linked to the overall development of smartphone design and functionality. As smartphones continue to advance, adhesive technologies will likely also progress to meet the demands of new features and form factors.

What Future Trends Can We Expect in Smartphone Adhesive Development?

Ongoing advancements will likely influence the future trends in smartphone adhesive development in materials science, the demand for more compact and durable devices, and emerging technologies. Here are some potential trends to expect in the development of smartphone adhesives:

Flexible and Foldable Device Adhesives:

- As foldable and adjustable smartphones become more common, an increased focus will be on adhesives that can withstand repeated bending without losing their adhesive properties. These adhesives will need to provide flexibility while maintaining strong bonds.

Advanced Thermal Management Adhesives:

- With smartphones becoming more powerful, efficient thermal management is crucial. Future adhesives may have enhanced thermal conductivity properties to dissipate heat from high-performance components like processors and cameras effectively.

Biodegradable and Sustainable Adhesives:

- The industry is likely to see a growing emphasis on environmentally friendly adhesives. Manufacturers may explore using biodegradable materials or adhesives with minimal environmental impact in response to increasing awareness of sustainability.

Innovative Adhesives with Sensing Capabilities:

- Adhesives with sensing capabilities may be developed to monitor factors like temperature, pressure, or structural integrity. This could contribute to the overall health monitoring of a device and enable predictive maintenance.

Nano-Adhesives for Miniaturization:

- Nano-adhesives with tiny particles may continue to be used for more robust and precise bonds. These adhesives are well-suited for the miniaturization trend in smartphones, allowing for compact designs without compromising structural integrity.

Enhanced Water and Dust Resistance:

- Adhesives will likely play a key role in further improving smartphones’ water and dust resistance. Future developments may focus on creating even more effective barriers against environmental elements.

Rapid Curing Technologies:

- Rapid-curing adhesives could become more prevalent in manufacturing processes, allowing quicker production cycles. This could enhance efficiency in smartphone assembly lines.

Improved Durability for Harsh Environments:

- Adhesives that withstand harsh environmental conditions, such as extreme temperatures or high humidity, may become more common. This is especially important as smartphones continue to be used in diverse climates and situations.

Adhesives for Advanced Display Technologies:

- As display technologies advance, adhesives must be tailored to support these innovations. For example, adhesives for under-display cameras or foldable displays will be designed to meet the specific requirements of these technologies.

Customized Adhesives for Specific Components:

- Adhesives may be formulated and customized to particular smartphone components, considering each part’s unique requirements for bonding and overall device performance.

It’s important to note that these trends are speculative, and the actual direction of adhesive development will depend on various factors, including technological breakthroughs, market demands, and environmental considerations. The smartphone industry is dynamic, and ongoing research and innovation will continue to shape the future of adhesive technologies in these devices.

Conclusion:

In conclusion, Smartphone Adhesive is an often overlooked but crucial element in the design and functionality of our beloved devices. Understanding the nuances of these adhesives provides insights into the engineering marvels behind our smartphones and empowers consumers to make informed decisions about device maintenance and repair. Stay tuned as we delve deeper into the world of Smartphone Adhesives, keeping you at the forefront of technological advancements in the mobile industry.

DeepMaterial

Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. More…

UV Curing Adhesives

UV light cure have a number of benefits making them a popular choice among many product assembly and manufacturing applications. Many UV light cure adhesives can provide a nearly instantaneous bond to difficult substrates like glass and plastic. UV cure adhesives often require an accelerator or UV light for a bond to form.

Adhesive Blogs & News

The latest adhesive industry science and technology, Deepmaterial news, and market trends and forecasts.

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives UV adhesives have been widely used in many fields such as electronics, optics, and medicine due to their advantages of rapid curing, high bonding strength, and environmental protection. However, their rapid curing property also brings challenges in some application scenarios.

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields LED UV glue adhesive has been widely applied in numerous fields due to its advantages such as rapid curing and easy operation. However, in fields with stringent safety requirements like medical and food packaging, its biocompatibility after curing

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions The dispensing process is an important part of the application of LED UV glue adhesive, and the quality of this process directly affects the final performance of the product. The physical properties of the glue,

Aging Mechanism and Modification Strategies of LED UV Glue under Long-term Ultraviolet Irradiation

Aging Mechanism and Modification Strategies of LED UV Glue under Long-term Ultraviolet Irradiation LED UV glue, with its advantages of fast curing speed, high bonding strength, and environmental friendliness, has been widely used in fields such as optical device packaging, electronic assembly, and medical devices. However, in scenarios where it is exposed to ultraviolet environments