- Home

- >

- Application

- >

- Laptop Adhesive

Laptop Adhesive

In the intricate world of portable devices, the unassuming yet indispensable component known as laptop adhesive quietly takes center stage. This comprehensive guide aims to unravel the significance of these adhesives in the manufacturing and repair of laptops, shedding light on their pivotal role in ensuring structural integrity, conductivity, and efficient thermal management. As we embark on this exploration, we will explore the diverse types of adhesives available, their impact on device durability, and the evolving landscape of eco-friendly alternatives.

Table of Contents

ToggleWhat is laptop adhesive, and why is it important?

Specialized bonding agents are crucial for assembling and maintaining portable devices, and laptop adhesives are often inconspicuous yet indispensable. With various formulations, these adhesives significantly contribute to laptops’ overall functionality and longevity.

Significance in Device Construction

The importance of laptop adhesives lies in their ability to create robust connections between different device components. They serve as the invisible backbone, ensuring the structural integrity of laptops and enabling seamless performance. This connectivity extends beyond physical elements, impacting thermal management and electrical conductivity.

Enhancing Robustness

Laptop adhesives play a crucial role in fortifying device durability and structural integrity. By securely bonding components, they contribute to the overall robustness of laptops, safeguarding against external stresses and enhancing the device’s resilience.

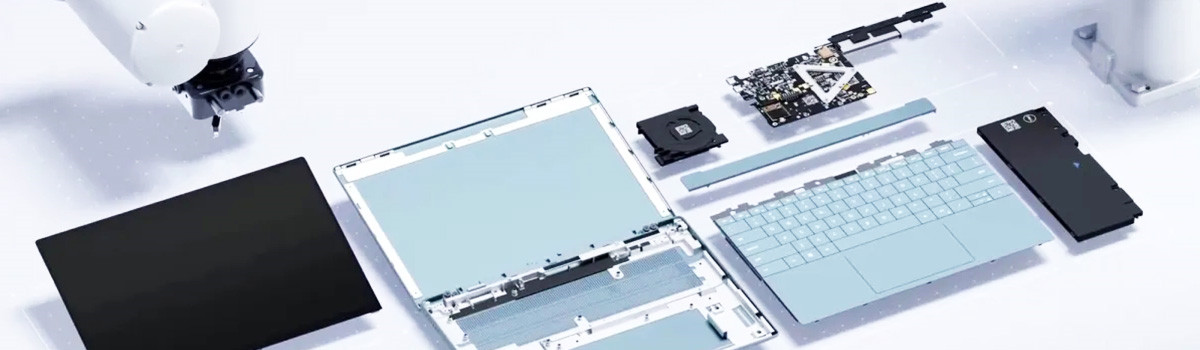

Tailored Adhesives for Specific Components

The diversity in laptop designs necessitates tailored adhesives for specific components such as screens or casings. Understanding these specialized adhesives is essential for effective repairs and ensuring optimal performance of each device part.

Impact on Thermal Conductivity

Beyond structural considerations, laptop adhesives significantly influence thermal conductivity. Proper thermal management is essential for preventing overheating, and the suitable adhesive ensures efficient heat dissipation, contributing to laptops’ overall performance and longevity.

What are the different types of laptop adhesives available in the market?

Understanding the specific roles and formulations of these laptop adhesives is crucial for manufacturers to ensure the reliability,

longevity, and performance of these portable computing devices in the hands of consumers. Each type serves a unique purpose, contributing to modern laptops’ intricate design and functionality.

Types of Laptop Adhesives:

Thermal Interface Materials (TIMs):

- Purpose:TIMs enhance the thermal conductivity between the laptop’s central processing unit (CPU) and the heat sink. They ensure efficient heat dissipation, preventing overheating and potential damage to internal components.

- Standard Formulations:Silicone-based TIMs are prevalent due to their thermal stability and effective heat transfer properties.

Structural Adhesives:

- Purpose:Structural adhesives are employed to bond various components of a laptop’s chassis, such as metal and plastic. They contribute to the overall rigidity and durability of the device.

- Standard Formulations:Epoxy adhesives are widely used for structural bonding in laptops, providing solid and resilient bonds.

Display Adhesives:

- Purpose:These adhesives are specifically formulated for bonding the display components, such as the LCD panel and the frame. They ensure a secure attachment while maintaining optical clarity.

- Standard Formulations:Acrylic-based adhesives are popular for display bonding due to their optical transparency and resistance to yellowing over time.

Conductive Adhesives:

- Purpose:Conductive adhesives connect and secure electrical components, such as connectors and circuits, within the laptop. They provide both adhesive properties and electrical conductivity.

- Standard Formulations:Silver-filled adhesives are often used for their excellent electrical conductivity and adhesive strength.

Pressure-Sensitive Adhesives (PSAs):

- Purpose:PSAs bond lightweight components, such as labels, rubber feet, or decorative elements, onto the laptop’s surface. They offer immediate adhesion upon contact.

- Standard Formulations:Acrylic-based PSAs are preferred for their versatility, offering a balance of adhesion and cohesion.

How do laptop adhesives contribute to the durability and structural integrity of devices?

Within the intricate world of laptop manufacturing, the role of adhesives is paramount in ensuring these portable devices’ durability and structural integrity. The careful selection and application of laptop adhesives play a vital part in enhancing the robustness and stability of various components, contributing to laptops’ overall longevity and reliability. In this exploration, we will delve into how laptop adhesives fortify these essential gadgets’ structural integrity.

Contribution of Laptop Adhesives to Durability:

Securing Components:

Adhesives are instrumental in securing diverse components within a laptop’s chassis. They create bonds between metal, plastic, and other materials, preventing unintended movements or vibrations that could compromise the device’s structural integrity.

Thermal Management:

Thermal Interface Materials (TIMs) are a specialized type of adhesive crucial for managing heat within laptops. By facilitating efficient heat transfer between the central processing unit (CPU) and the heat sink, TIMs prevent overheating, which can lead to component failure.

Reinforcing Chassis:

Structural adhesives play a crucial role in reinforcing the laptop’s chassis. By bonding metal and plastic parts, these adhesives contribute to the overall rigidity of the device, ensuring it can withstand the stresses of daily use and transportation.

Enhancing Structural Integrity:

Display Assembly:

Adhesives specifically formulated for displays create a solid bond between the LCD panel and the frame. This formulation ensures the stability of the display and prevents dust and contaminants from infiltrating the internal components.

Circuit Connection:

Conductive adhesives are critical for securing and electrically connecting components within the laptop. They contribute to structural integrity by maintaining secure connections between circuits, connectors, and other electrical elements.

Bonding Lightweight Components:

Pressure-sensitive adhesives (PSAs) bond lightweight components, such as labels and decorative elements, onto the laptop’s surface. While not bearing significant loads, these adhesives contribute to the overall aesthetics and user experience.

Are there specialized adhesives for specific laptop parts, like screens or casings?

Understanding the nuances of these specialized adhesives is essential for laptop manufacturers to ensure the precise assembly and functionality of individual components, contributing to the overall quality and performance of the devices. Each adhesive is tailored to meet the specific demands of the element it serves, reflecting the intricate nature of laptop design and construction.

Adhesives for Display Components:

- Display Bonding: Adhesives formulated for display components, such as the LCD panel and the frame, are crucial for creating a secure and durable bond. These adhesives must maintain optical clarity to ensure a high-quality visual experience for users.

- Acrylic-Based Formulations:Many adhesives for display applications are acrylic-based due to their transparency and resistance to yellowing over time. These formulations provide the necessary strength and clarity required for adequate display bonding.

Thermal Interface Materials (TIMs):

- Heat Management: Thermal Interface Materials are specialized adhesives designed to enhance the thermal conductivity between the laptop’s central processing unit (CPU) and the heat sink. Efficient heat transfer is essential for preventing overheating and ensuring the longevity of internal components.

- Silicone-Based Formulations: TIMs often utilize silicone-based formulations, which offer excellent thermal stability and conductivity. These adhesives help dissipate heat efficiently, contributing to the overall thermal management of the laptop.

Structural Adhesives for Chassis:

- Reinforcing the chassis: Structural adhesives bonding materials like metal and plastic to support the laptop’s chassis. These adhesives contribute to the overall rigidity of the device, ensuring it can withstand physical stresses.

- Epoxy-Based Formulations:Epoxy adhesives are commonly used for structural bonding in laptops. Their solid and resilient bonds make them suitable for securing materials within the laptop’s casing.

Conductive Adhesives for Electrical Components:

- Circuit Connection: Conductive adhesives are crucial in connecting and securing electrical components within the laptop. These adhesives provide both adhesion and electrical conductivity, ensuring reliable connections.

- Silver-Filled Formulations: Silver-filled adhesives are often preferred for their excellent electrical conductivity. They are utilized in applications where both adhesive strength and electrical connectivity are essential.

Can laptop adhesives affect the performance or cooling of the device?

While often overlooked, laptop adhesives play a crucial role in the performance and cooling of these devices. The type and application of adhesives can significantly impact thermal conductivity, structural integrity, and overall efficiency. In this exploration, we delve into how laptop adhesives can influence the performance and cooling of these essential computing devices.

Thermal Interface Materials (TIMs) and Cooling:

- Efficient Heat Transfer:Thermal Interface Materials are designed to enhance the thermal conductivity between the laptop’s central processing unit (CPU) and the heat sink. Efficient heat transfer is critical for preventing overheating and maintaining optimal performance.

- Impact on Cooling System:The choice of TIMs directly influences the effectiveness of the laptop’s cooling system. High-quality TIMs ensure that heat generated by the CPU is efficiently dissipated, preventing thermal throttling and maintaining stable performance.

Structural Adhesives and Performance:

- Rigidity and Performance: Structural adhesives contribute to the overall rigidity of a laptop’s chassis. A well-bonded chassis ensures that internal components are securely in place, preventing vibrations that could impact performance or lead to component failure.

- Impact on Durability: The structural integrity of adhesives can affect the laptop’s durability. Sturdy construction helps maintain the alignment of components, preventing issues that might arise from structural instability during usage.

Conductive Adhesives and Electrical Performance:

- Maintaining Electrical Connections:Conductive adhesives are crucial for securing and electrically connecting components within the laptop. These adhesives are vital in maintaining reliable electrical connections, directly impacting the device’s overall electrical performance.

- Influence on Circuitry: The quality of conductive adhesives can affect the conductivity of circuits within the laptop. A well-formulated adhesive ensures that electrical signals travel efficiently, preventing signal degradation and resistance.

Overall Impact on Performance:

- Comprehensive Performance Consideration: The cumulative effect of various adhesives on different components influences the laptop’s overall performance. From the CPU and display to electrical connections, the collective contribution of adhesives is integral to the device’s functionality.

- Balancing Thermal and Structural Needs: Laptop manufacturers must balance the thermal requirements for efficient cooling and the structural needs for stability. Optimal adhesive selection is critical to achieving this delicate balance.

What factors should one consider when choosing a laptop adhesive for repair or assembly?

Selecting the suitable laptop adhesive is a critical aspect of repair or assembly, influencing the device’s performance, durability, and overall functionality. Several factors must be considered to ensure optimal results. This exploration delves into the essential considerations when choosing a laptop adhesive for repair or assembly, covering aspects such as material compatibility, application methods, and environmental factors.

Material Compatibility:

- Substrate Compatibility: The adhesive must be compatible with the materials being bonded. Laptops often have a variety of materials, including metals, plastics, and glass. Choosing an adhesive with broad substrate compatibility ensures a strong and durable bond across different components.

- Thermal Compatibility: For components that generate heat, such as the central processing unit (CPU), selecting an adhesive with good thermal stability and conductivity, such as certain Thermal Interface Materials (TIMs), is crucial to prevent overheating.

Application Method:

- Ease of Application: The chosen adhesive should align with the repair or assembly process. Some adhesives come in convenient applicators like syringes or pens, facilitating precise application in tight spaces or intricate components.

- Curing Time: The curing time of the adhesive is a crucial consideration. Some applications may require fast-curing adhesives for quick repairs, while others may benefit from slower-curing adhesives to allow for adjustments during assembly.

Environmental Factors:

- Temperature Resistance: Adhesives used in laptops should withstand the temperature variations that devices may encounter during operation. Ensuring the adhesive can handle high and low temperatures is vital for long-term reliability.

- Environmental Impact: Considering the environmental impact of the adhesive is essential for sustainability. Opting for adhesives with low volatile organic compound (VOC) content or eco-friendly formulations aligns with modern ecological standards.

Performance Requirements:

- Structural Requirements: Depending on the application, the adhesive may need to provide structural support. Epoxy adhesives, known for their strength, are suitable for applications where structural integrity is crucial.

- Electrical Conductivity: In cases where the adhesive is used for electrical components, such as conductive adhesives for circuit connections, ensuring proper electrical conductivity without signal interference is essential.

Cost Considerations:

Budgetary Constraints: While performance is crucial, considering budget constraints is also necessary. High-quality adhesives are available at various prices, and choosing one that aligns with the budget without compromising performance is critical.

How does one properly apply laptop adhesive during repairs or assembly?

Laptop repairs and assembly often involve laptop adhesive to ensure a secure and durable bond between components. Whether fixing a loose screen, replacing a keyboard, or working on any other part of a laptop, understanding the correct application techniques for laptop adhesive is crucial. Here’s a step-by-step guide to help you apply laptop adhesive effectively:

Surface Preparation:

- Begin by cleaning the surfaces that will be bonded with the adhesive. Remove dust, grease, or residue using a gentle cleaning and lint-free cloth.

- Ensure the surfaces are dehydrated before applying the adhesive to promote optimal bonding.

Choosing the Right Adhesive:

- Different laptops may require different types of adhesives based on the materials involved. Common types include double-sided tape, liquid adhesive, and adhesive strips.

- Consider the specific needs of your repair or assembly job and select an adhesive suitable for your working materials.

Applying Double-Sided Tape:

- Cut the tape to the desired length using scissors or a precision knife.

- Carefully place the tape on the designated surface, ensuring complete coverage without any gaps.

- Press down firmly to secure the tape in place.

Using Liquid Adhesive:

- Apply a small amount of liquid adhesive to one of the surfaces using a syringe or precision applicator.

- Spread the adhesive evenly across the surface, avoiding excess that could squeeze out during assembly.

- Quickly join the surfaces together and apply gentle pressure until the adhesive sets.

Adhesive Strips Application:

- Peel off the protective backing from the adhesive strip.

- Align the strip with the designated area and press it firmly into place.

- Smooth out any air bubbles or wrinkles to ensure a secure bond.

Allowing Adequate Cure Time:

- After assembly, allow the adhesive to cure for the recommended time before putting stress on the bonded components.

- Follow the manufacturer’s instructions for optimal results.

- Following these step-by-step guidelines, you can ensure the proper application of laptop adhesive, promoting a reliable and long-lasting bond in your repair or assembly projects.

Are there eco-friendly or sustainable laptop adhesive options available?

In today’s rapidly evolving technological landscape, laptops have become indispensable tools for both work and leisure. However, as we delve into sustainability, the question arises: Are eco-friendly or sustainable laptop adhesive options available? This inquiry opens the door to explore adhesive alternatives that not only adhere to the demands of modern computing but also align with environmentally conscious practices.

Eco-friendly Laptop Adhesives:

- Biodegradable Materials:Some laptop adhesives utilize biodegradable materials, minimizing their environmental impact. These adhesives break down naturally over time, reducing the ecological footprint associated with traditional adhesives.

- Recyclable Packaging:Manufacturers are increasingly focusing on sustainable packaging for laptop adhesives. Packaging made from recyclable materials reduces waste and encourages responsible disposal practices among consumers.

- Water-Based Adhesives:Water-based laptop adhesives have gained popularity for their reduced toxicity and lower environmental impact than solvent-based alternatives. These adhesives eliminate or significantly reduce the emission of volatile organic compounds (VOCs).

Benefits of Eco-friendly Laptop Adhesives:

- Reduced Environmental Impact:By opting for eco-friendly laptop adhesives, consumers contribute to reducing harmful effects on ecosystems and wildlife. These adhesives break down naturally, preventing long-term environmental damage.

- Healthier Indoor Air Quality:Water-based adhesives, in particular, enhance indoor air quality by minimizing the release of harmful VOCs. This reduction is crucial for users who spend extended periods near their laptops.”

- Corporate Responsibility:Companies investing in sustainable laptop adhesives showcase a commitment to corporate responsibility. This commitment appeals to environmentally conscious consumers and sets a positive example for others in the industry.

Challenges and Future Prospects:

- Cost Considerations:While eco-friendly alternatives bring numerous benefits, the initial costs may be higher. As demand grows, however, economies of scale could help reduce these costs over time.

- Innovation Opportunities:Pursuing sustainable laptop adhesives encourages innovation in materials science and technology. This ongoing development holds the promise of even more environmentally friendly solutions.

As we navigate the evolving landscape of technology, the choice of laptop adhesive emerges as a pivotal aspect of a sustainable future. By embracing eco-friendly alternatives, we contribute to a healthier planet and drive innovation towards a more environmentally conscious computing experience.

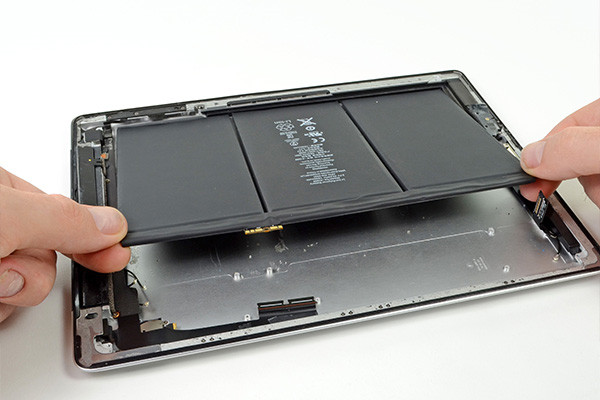

Can laptop adhesives be removed or replaced without damaging the device?

In the ever-evolving world of technology, the adhesive that secures the components of a laptop plays a crucial role. A pertinent question arises: Can laptop adhesives be removed or replaced without damaging the device? This inquiry delves into the realm of safe removal methods and considerations for replacing adhesives, ensuring the longevity and functionality of laptops without risking harm.

Safe Removal Methods:

- Heat Application:Utilizing controlled heat is a standard method for softening adhesives without causing damage. Heat guns or hair dryers set to a low temperature can gently warm the adhesive, making it more pliable for removal.

- Isopropyl Alcohol:Isopropyl alcohol is effective in dissolving adhesives. Applied with a soft cloth or cotton swab, it can break down the adhesive’s bond, allowing for careful removal without leaving residue.

- Adhesive Removers:Commercial adhesive removers formulated for electronics provide a targeted solution. Specifically designed to dissolve adhesives effectively, these products minimize the risk of damage to electronic components.

Considerations for Replacing Adhesives:

- Compatibility:When replacing adhesives, ensuring compatibility with the laptop’s materials is crucial. Using adhesives that match the original specifications helps maintain the structural integrity of the device.

- Thickness and Strength: The thickness and strength of the adhesive play a vital role in securing components, and replacing adhesives with similar thickness and strength options is essential to uphold the laptop’s structural stability.

- Residue Prevention:Proper cleaning and preparation are paramount when replacing adhesives. Residual adhesive or cleaning agents can interfere with the new bond, potentially compromising its effectiveness.

Benefits of Safe Removal and Replacement:

- Extended Device Lifespan:Safely removing and replacing adhesives contribute to the overall longevity of a laptop. This practice ensures that components stay securely in place, preventing issues related to loose or displaced parts.

- Maintenance of Aesthetics:A careful adhesive replacement process helps maintain the aesthetic appeal of laptops. Avoiding damage during removal prevents unsightly marks or blemishes on the device’s surface.

- User-Friendly Repairs:Devices that allow for safe adhesive removal and replacement facilitate user-friendly repairs. This accessibility empowers users to address issues without needing professional intervention, promoting a more sustainable approach to device maintenance.

As technology advances, understanding safe methods for removing and replacing laptop adhesives becomes increasingly crucial. By adopting these practices, users can confidently navigate repairs and upgrades, ensuring that their devices remain functional and aesthetically pleasing over time.

How do laptop adhesives contribute to waterproofing or resistance against external elements?

In the dynamic landscape of laptop technology, ensuring the resilience of these devices against external elements is paramount. A vital component of this protection is the role of laptop adhesives. This exploration will explore how certain adhesives contribute to waterproofing, enhancing laptops’ resistance against external elements and potential damage.

Waterproofing Mechanisms:

- Sealing Micro Gaps:Laptop adhesives often contain properties that allow them to fill micro gaps between components. This sealing function is a barrier against water intrusion, preventing moisture from reaching sensitive internal circuitry.

- Hydrophobic Coatings:Some laptop adhesives come equipped with hydrophobic coatings, which repel water. These coatings create a barrier on the laptop’s surface, preventing water from adhering and seeping into vulnerable areas.

- Chemical Resistance:Certain adhesives exhibit resistance to chemicals, including water. This chemical resilience ensures that the adhesive maintains its integrity even when exposed to moisture, contributing to the overall waterproofing of the laptop.

Benefits of Waterproofing Laptop Adhesives:

- Enhanced Durability:Waterproof adhesives contribute to the overall durability of laptops. By preventing water damage, these adhesives help extend the lifespan of electronic components, reducing the risk of malfunctions caused by moisture exposure.

- Protection Against Accidents:Laptops are prone to accidental spills or exposure to rain. Waterproof adhesives act as a protective barrier, mitigating the potential harm caused by liquid ingress and safeguarding the internal components from damage.

- Improved Reliability in Diverse Environments:Laptops are used in various environments, from offices to outdoor locations. Adhesives with waterproofing properties make laptops more reliable in diverse conditions, allowing users to use their devices in different settings without compromising performance.

Considerations for Manufacturers:

- Material Compatibility:Manufacturers must select adhesives compatible with the laptop’s materials to ensure effective waterproofing without compromising structural integrity.

- Testing and Certification:Rigorous testing and certification processes are essential to verify the effectiveness of waterproofing adhesives. These processes ensure that laptops meet industry standards for water resistance and durability.

- User Education: Providing users with information on the water-resistant features of their laptops, including the role of adhesives, enhances awareness and encourages responsible usage in various environments.

Are there any common issues or challenges associated with laptop adhesives?

While laptops have become integral to our daily lives, the reliability and performance of these devices hinge on various components, including laptop adhesives. However, the use of adhesives in laptops has its challenges. This exploration highlights common issues and challenges associated with laptop adhesives, ranging from adhesive failure to compatibility concerns and improper application.

Common Issues and Challenges:

Adhesive Failure:

- Bond Weakness:Adhesive failure can occur if the bond between components and adhesives is not strong enough, leading to the dislodgment of parts and affecting the laptop’s structural integrity.

- Temperature Sensitivity:Extreme temperatures can compromise adhesive strength. Adhesives that are not resistant to temperature variations may weaken or fail, leading to potential issues with laptop functionality.

Compatibility Issues:

- Material Mismatch:Laptop adhesives must be compatible with the materials they are bonding with. Mismatched adhesives may not adhere effectively, causing issues such as separation or degradation of components.

- Chemical Reactions:Incompatibility with other materials or chemicals in the laptop can lead to adverse reactions, affecting the adhesive and the components to which it bonds.

Improper Application:

- Inadequate Cleaning:Adhesive application requires a clean surface. If components are not adequately cleaned before application, contaminants may compromise the bond, leading to issues like poor adhesion or eventual failure.

- Incorrect Amounts:Applying too much or too little adhesive can result in uneven bonding or insufficient support for components, contributing to potential performance problems.

Mitigation Strategies:

Quality Control Measures:

Implementing rigorous quality control measures during manufacturing helps identify and address adhesive issues before laptops reach consumers.

Material Research and Development:

Continuous research into advanced adhesive materials that offer improved strength, durability, and compatibility can mitigate common challenges associated with adhesives.

User Education:

- Providing users with information on proper laptop care and maintenance, including the role of adhesives, can help prevent issues related to environmental factors or mishandling.

- Understanding and addressing these challenges associated with laptop adhesives are crucial for manufacturers and users. As technology evolves, the industry must adopt innovative solutions to enhance adhesive performance, ensuring laptops remain reliable and resilient in the face of various challenges.

Can laptop adhesives be used for DIY repairs, or is professional assistance necessary?

Using laptop adhesives in DIY repairs has become a subject of interest among users seeking to address minor issues or perform component replacements. However, the complexity of laptop structures and the specialized nature of adhesives raise questions about the feasibility and safety of DIY repairs versus seeking professional assistance.

Feasibility of DIY Laptop Repairs Using Adhesives:

Understanding Laptop Components:

- Component Identification:DIY repairs must accurately identify laptop components and understand their structural integration to determine the necessity of adhesive use.

- Knowledge of Adhesive Types:Familiarity with the specific types of adhesives required for various components is essential to ensure proper bonding and functionality.

Repair Scenarios:

- Battery Replacement:Some laptop battery replacements might necessitate adhesive removal and reapplication for secure placement.

- Screen or Display Repairs:Repairing or replacing laptop screens often involves adhesive usage to secure display components properly.

- Internal Component Adjustments: In some instances, repositioning or securing internal components might require adhesives for stability.

Tools and Techniques:

- Proper Tools:DIY repairers need specialized tools such as spudgers, adhesive remover solutions, and precision applicators to handle adhesives effectively.

- Precision Application:Accurate application of adhesives is critical for successful repairs; improper application can affect laptop functionality and durability.

Challenges and Risks:

- Complexity and Precision:Laptop structures are intricate, and adhesive application demands precision; improper handling can lead to component damage or malfunction.

- Adhesive Compatibility:Using the wrong adhesive or misapplying it may compromise the laptop’s structural integrity and performance.

Professional Assistance vs. DIY:

- Professional Expertise:Trained technicians possess expertise in handling adhesives, ensuring precise application, and minimizing risks associated with DIY repairs.

- Warranty Consideration:DIY repairs might void manufacturer warranties, while professional repairs often maintain warranty validity.

Are there any safety precautions one should follow when handling laptop adhesives?

While working with laptop adhesives, it’s crucial to prioritize safety measures to mitigate potential risks associated with these materials. Adhesives used in laptops often contain chemicals and compounds that require careful handling to ensure the safety of the user and the surrounding environment.

Safety Precautions for Handling Laptop Adhesives:

Personal Protective Equipment (PPE):

- Protective Gloves:Wear chemical-resistant gloves to prevent skin contact and potential irritation or allergic reactions caused by adhesive components.

- Safety Glasses or Goggles:Protect your eyes from splashes or accidental contact with adhesives by wearing appropriate eye protection.

Adequate Ventilation:

- Work in well-ventilated areas or utilize fume hoods to minimize exposure to potentially harmful vapors or fumes emitted by adhesives. Proper ventilation prevents inhalation of hazardous substances.

Handling Procedures:

- Read Safety Data Sheets (SDS):Familiarize yourself with the SDS provided by the adhesive manufacturer, which contains crucial information about handling, storage, and emergency procedures.

- Avoid Skin Contact:Prevent direct contact with adhesives by wearing appropriate clothing that covers exposed skin and promptly clean any accidental spills or splashes.

Storage and Disposal:

- Proper Storage: To maintain the integrity of adhesives, store them in designated areas away from heat sources and incompatible materials, following manufacturer guidelines.

- Safe Disposal:Dispose of adhesive waste according to local regulations and guidelines. Avoid pouring adhesives down drains or disposing of them in regular waste bins.

Emergency Preparedness:

- First Aid Measures:Ensure access to first aid supplies in case of accidental exposure or injury. Rinse affected skin thoroughly with water in case of contact and seek medical attention if necessary.

- Emergency Response:Be aware of emergency procedures in case of spills, exposure, or accidents involving adhesives. Have appropriate cleanup materials and protocols in place.

Training and Awareness:

- Training Programs:Train individuals handling adhesives, emphasizing safety protocols, proper handling techniques, and emergency response procedures.

- Awareness and Communication:Maintain clear communication regarding safety guidelines and encourage a culture of safety awareness among all individuals involved in handling adhesives.

How do manufacturers test the quality and reliability of laptop adhesives?

Ensuring the quality and reliability of laptop adhesives is paramount in the manufacturing process to guarantee the durability and performance of these devices. Manufacturers use rigorous testing methodologies to scrutinize the adhesives, ensuring they meet stringent standards and perform optimally in various conditions.

Adhesive Material Analysis:

- Material Composition Analysis:Manufacturers conduct in-depth analyses of the adhesive material composition using spectroscopy and microscopy to ensure the ingredients meet desired specifications and quality standards.

- Chemical and Thermal Stability Testing:Adhesives undergo testing to assess their chemical stability under different environmental conditions and their thermal resistance to ensure they can withstand the range of temperatures laptops might encounter during operation.

Mechanical Testing:

- Strength and Bonding Tests:Manufacturers perform tests to evaluate the adhesive’s bonding strength under tension, compression, and shear forces. These tests, such as peel, lap shear, and tensile tests, determine the adhesive’s ability to maintain structural integrity.

- Flexibility and Durability Assessments:Adhesives are subjected to bending and flexing tests to assess their ability to maintain bonding integrity under varying degrees of mechanical stress, mimicking real-world usage scenarios.

Environmental and Endurance Testing:

- Temperature and Humidity Cycling:Adhesives undergo cycles of extreme temperatures and humidity levels to simulate long-term exposure, ensuring they retain their adhesive properties without degradation.

- Vibration and Shock Testing:Laptops are subjected to vibration and shock tests to evaluate how well the adhesives withstand physical impacts, simulating transportation or accidental drops.

- Accelerated Aging Tests:Manufacturers conduct accelerated aging tests to predict the adhesive’s performance and lifespan over an extended period by subjecting them to harsh conditions, such as high temperatures and UV exposure.

- Adhesive Application and Process Validation:

- Application Consistency Tests:Manufacturers ensure uniform and precise application of adhesives across laptop components by employing quality control measures and inspecting adhesive application processes.

- Process Validation:Validation of the adhesive application process ensures that it aligns with standardized procedures and contributes to the overall quality and reliability of the laptop assembly.

What innovations or advancements are being made in the field of laptop adhesives?

In recent years, the field of laptop adhesives has undergone significant advancements and innovations, revolutionizing the way laptops are assembled and enhancing their durability and performance. Engineers and researchers have been exploring various materials and techniques to improve adhesive properties, ensuring better bonding, thermal management, and overall structural integrity of laptops.

Advancements in Laptop Adhesives:

- Nanotechnology Integration:Researchers are exploring nanomaterials to develop adhesives with enhanced properties like increased strength, better conductivity, and improved heat dissipation. Nanoparticles, such as graphene, carbon nanotubes, and nanodiamonds, are incorporated into adhesives to enhance thermal conductivity and mechanical strength.

- Structural Flexibility:Adhesives that offer robust bonding and flexibility are being developed to accommodate the demand for thinner and lighter laptops. These adhesives allow for structural integrity while enabling flexibility for sleek and portable laptop designs.

- Eco-Friendly Adhesives:Efforts are being made to create laptop adhesives that are environmentally friendly and sustainable. Biodegradable adhesives derived from natural sources or recyclable materials are being researched to reduce the environmental impact of laptop manufacturing.

- Thermal Management Solutions:Advanced adhesives with superior thermal conductivity properties are being developed to efficiently transfer heat away from critical components like CPUs and GPUs. This practice helps prevent overheating issues and improves laptops’ overall performance and lifespan.

- Self-Healing Adhesives:Innovations are being made in self-healing adhesives that can repair minor damages or cracks autonomously, contributing to the longevity and durability of laptops.

- Improved Adhesive Application Techniques:Manufacturers are exploring new application methods and technologies to ensure precise and uniform adhesive application, optimizing laptops’ overall performance and reliability.

The field of laptop adhesives is undergoing a transformative phase with advancements geared toward enhancing durability, thermal management, and environmental sustainability. These innovations are crucial in enabling the creation of more robust, efficient, and eco-friendly laptops to meet the evolving needs of consumers and the industry.

Can laptop adhesives deteriorate over time, and how can one prevent degradation?

Laptop adhesives, crucial for device integrity, can degrade over time due to various environmental factors. Understanding degradation mechanisms and implementing preventive measures are essential for maintaining adhesive efficacy and ensuring prolonged laptop functionality and reliability.

Factors Contributing to Degradation:

- Temperature variations leading to softening or hardening of adhesives

- Moisture exposure causing adhesive weakening or delamination

- Oxidation and UV exposure impacting adhesive stability and strength

- Mechanical stress inducing adhesive fatigue and failure over time

Preventive Measures to Counter Degradation:

- Controlled Environmental Conditions:Maintaining stable temperatures and humidity helps mitigate adverse adhesive effects.

- Quality Adhesive Selection:Using adhesives engineered for specific environmental resistance and durability.

- Protective Coatings or Encapsulation:Shielding adhesives from moisture, UV radiation, and oxidation to prolong their lifespan.

- Regular Maintenance and Inspection:Monitoring for signs of adhesive degradation and undertaking timely repairs or replacements.

- Adhesive Compatibility with Components:Ensuring compatibility between adhesives and different laptop materials to prevent chemical reactions causing deterioration.

- Proper Handling and Installation:Employing correct application techniques and handling procedures during assembly to prevent premature degradation.

- Periodic Testing and Evaluation:Conducting routine tests to assess adhesive performance and effectiveness over time.

Adopting a proactive approach by addressing environmental stressors, employing suitable adhesives, and implementing preventive maintenance measures can significantly mitigate the degradation of laptop adhesives, ensuring prolonged device functionality and structural integrity.

Are there any alternative solutions or technologies that might replace traditional laptop adhesives in the future?

The quest for alternative solutions to traditional laptop adhesives intensifies as technology advances. Innovations in materials science and engineering have spurred the exploration of diverse technologies poised to revolutionize laptop assembly, offering promising alternatives to conventional adhesives, aiming for enhanced performance, sustainability, and versatility.

- Nanomaterials and Nanotechnology:Exploring adhesive-free bonding through nanomaterial-based interlocking or surface interactions, reducing dependency on traditional adhesives.

- Biodegradable and Bioinspired Adhesives:Developing eco-friendly adhesives mimicking natural adhesion mechanisms, aiming for reduced environmental impact and biodegradability.

- Dry Adhesion Methods:Utilizing microstructures or surface modifications enables adhesion without traditional bonding agents, offering potential reusability and repairability.

- Self-Healing Polymers:Introducing materials with intrinsic healing properties, allowing repairs without conventional adhesive reapplication.

- Modular Assembly Mechanisms:Implementing magnetic or interlocking mechanisms for modular laptop components facilitates easy disassembly and reconfiguration.

- Non-Chemical Bonding: Exploring adhesion through molecular forces or intermolecular interactions reduces reliance on traditional adhesive materials.

- 3D Printing Techniques:Leveraging additive manufacturing for creating components with built-in bonding capabilities, potentially eliminating the need for separate adhesives.

- Reversible Bonding:Integrating heat-activated or reversible bonding methods for more straightforward repairs and component replacements.

These emerging alternative solutions signify a shift towards more adaptable, sustainable, and repair-friendly technologies in laptop manufacturing. As these innovations mature, they hold the potential to reshape the landscape of laptop assembly, emphasizing efficiency, environmental consciousness, and adaptability in adhesive technologies.

How do laptop adhesives differ from those used in other electronic devices?

Adhesives are integral to various electronic devices, but their composition and application can vary significantly. Understanding the distinctions in adhesive use between laptops and other electronics sheds light on the specific requirements and functionalities crucial for optimal device performance.

Composition and Formulation Differences

- Variety in adhesive types (epoxy, silicone, acrylic) based on device needs

- Specific additives for heat dissipation or electrical insulation in laptop adhesives

- Varying curing processes (thermal, UV, chemical) tailored to device specifications

Adhesive Applications Across Electronic Devices

- Smartphone and tablet adhesives emphasizing compactness and flexibility

- High-strength adhesives in wearables for durability and resistance to moisture

- Adhesives in larger electronic appliances focusing on stability and insulation

Environmental Considerations and Resistance

- Laptop adhesives engineered for wider temperature tolerances due to diverse usage scenarios

- Adhesives in rugged devices emphasizing resistance to shock, vibration, and harsh environments

- Electronics in controlled environments requiring adhesives with specific humidity or chemical resistance

Adhesive Placement and Purpose in Device Assembly

- Laptop adhesives are used for securing components, managing heat, and ensuring structural integrity

- Other device adhesives utilized for sealing, cushioning, or bonding specialized materials

- Varied stress points dictating adhesive application methods and bonding requirements

Technological Advancements and Research Trends

- Continuous innovation for thinner, more conductive adhesives in miniaturized electronics

- Integration of self-healing or reworkable adhesives for sustainability and repairability

- Enhanced adhesives for flexible and foldable device designs, adapting to bending stresses

Impact on Device Repairability and Lifecycle

- Laptop designs may incorporate adhesives hindering repair accessibility compared to modular assembly

- Repair challenges posed by specialized adhesives in sealed electronic devices

- Considerations for adhesive choice impacting device longevity and recyclability

Laptop adhesives present unique formulations and applications compared to other electronic devices, owing to their specific functional requirements and environmental considerations. Understanding these differences highlights the complexities of adhesive engineering across electronics. It underscores the need for tailored adhesive solutions to ensure optimal device performance, durability, and repairability in a rapidly evolving technological landscape.

Can excessive heat or cold affect the performance of laptop adhesives?

Laptop adhesives play a pivotal role in securing components within the device. The impact of extreme temperatures on these adhesives can be profound, potentially influencing laptops’ overall performance and longevity. Understanding how excessive heat or cold affects these adhesives is crucial for maintaining optimal laptop functionality.

Importance of Laptop Adhesives

- Securing internal components

- Ensuring structural integrity

- Heat dissipation and thermal management

Effects of Excessive Heat on Laptop Adhesives

- Softening or melting of adhesives

- Loss of adhesive strength

- Potential damage to internal components due to displacement

Impact of Extreme Cold on Laptop Adhesives

- Hardening or stiffening of adhesives

- Reduced flexibility and increased brittleness

- Potential cracking or delamination of adhesive layers

Factors Influencing Adhesive Resilience

- Quality and composition of adhesives

- Design and construction of laptop components

- Duration and intensity of temperature exposure

Mitigation Strategies for Temperature Effects

- Using adhesives with wider temperature tolerances

- Implementing thermal management solutions within laptops

- Limiting exposure to extreme temperature environments

Future Developments and Research Directions

- Advancements in adhesive technology for broader temperature resilience

- Enhanced testing methodologies to simulate real-world conditions

- Integration of adaptive materials for temperature-responsive adhesion

The impact of extreme temperatures on laptop adhesives is a critical consideration for ensuring the reliability and durability of portable devices. As technology advances, further research and innovative approaches in adhesive development and laptop design will be pivotal in enhancing their resilience to temperature variations, ultimately improving the performance and longevity of laptops in diverse environmental conditions.

Conclusion:

In conclusion, the journey through the realm of laptop adhesives has unveiled their multifaceted importance in device assembly and maintenance. From understanding the various types to addressing challenges and exploring future innovations, this guide provides a holistic view of these unassuming yet vital elements. The key takeaways underscore adhesives’ critical role in enhancing laptop robustness, the importance of considering environmental factors, and the ongoing advancements shaping the adhesive landscape. As laptops evolve, so will the adhesives that bind them, reflecting an ever-adapting synergy between technology and connectivity.

DeepMaterial

Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. More…

UV Curing Adhesives

UV light cure have a number of benefits making them a popular choice among many product assembly and manufacturing applications. Many UV light cure adhesives can provide a nearly instantaneous bond to difficult substrates like glass and plastic. UV cure adhesives often require an accelerator or UV light for a bond to form.

Adhesive Blogs & News

The latest adhesive industry science and technology, Deepmaterial news, and market trends and forecasts.

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy This article systematically expounds the quantitative relationship between the crosslinking density and the flexibility and hardness of adhesives. Combining the theories of polymer physics with experimental analysis methods, it reveals the mechanism of the action of the

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives UV adhesives have been widely used in many fields such as electronics, optics, and medicine due to their advantages of rapid curing, high bonding strength, and environmental protection. However, their rapid curing property also brings challenges in some application scenarios.

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields LED UV glue adhesive has been widely applied in numerous fields due to its advantages such as rapid curing and easy operation. However, in fields with stringent safety requirements like medical and food packaging, its biocompatibility after curing

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions The dispensing process is an important part of the application of LED UV glue adhesive, and the quality of this process directly affects the final performance of the product. The physical properties of the glue,