Transparent adhesive, often called clear glue or see-through bonding agent, is a versatile and invaluable material in various industries and everyday applications. Known for its ability to create strong and durable bonds while remaining nearly invisible upon application, this adhesive is an indispensable tool for tasks ranging from arts and crafts to industrial manufacturing. Its transparent nature allows for seamless integration, making it an ideal choice when aesthetics and reliability are paramount.

Table of Contents

ToggleWhat Is Transparent Adhesive?

Transparent adhesive is a versatile substance that bonds materials together while remaining nearly invisible upon application. It is commonly used in various industries and everyday applications due to its precise, see-through nature and strong adhesive properties.

Composition

Transparent adhesives are typically made from polymers or synthetic resins, which allow for a clear, colorless appearance. These adhesives often contain additives to enhance their bonding strength and flexibility. Some formulations may also include solvents to aid in application and drying.

Applications

The versatility of transparent adhesive makes it a popular choice in several fields:

- Crafts and DIY:Used in arts and crafts projects for its ability to bond materials like paper, plastic, and fabric without leaving visible marks.

- Construction:Employed in installing transparent materials such as glass panels, acrylic sheets, and plastics in buildings.

- Packaging:Widely utilized in manufacturing clear packages and labels to create strong, nearly invisible seals.

- Medical Industry:Used in medical devices and wound care products due to its hypoallergenic and transparent properties for skin applications.

Properties

Key characteristics of transparent adhesive include:

- Clarity: Maintains transparency after application, ensuring a seamless look between bonded surfaces.

- Adhesion Strength:Provides strong bonding capabilities across various materials, ensuring durability.

- Flexibility: Offers some flexibility after curing, allowing for movement without compromising the bond.

- Water and Heat Resistance:Some formulations resist water, heat, or other environmental factors, depending on the specific product.

Application Techniques

The application of transparent adhesive can vary based on the material and purpose, but standard methods include:

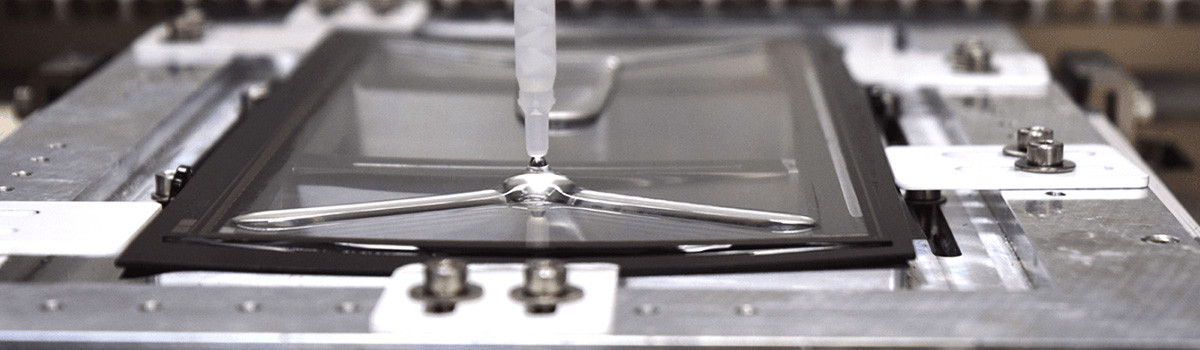

- Direct Application:A nozzle or applicator is used to apply the adhesive directly onto the surface.

- Spray Application:Employing spray bottles or specialized equipment for larger surfaces or distribution.

- Brushing or Rolling:Utilizing brushes or rollers for controlled and precise application on specific areas.

What Are the Types of Transparent Adhesives Available?

Regarding transparent adhesives, several varieties cater to diverse needs, offering different properties and applications. Here are the main types available:

Cyanoacrylate Adhesives (Super Glue)

- These adhesives, commonly known as superglue, are fast-acting and bond quickly to plastics, rubber, and metals.

- They’re highly efficient for minor repairs and intricate bonding due to their rapid setting and stronghold within seconds.

- It is best used for projects requiring precision and quick results.

Epoxy Resin Adhesives

- Epoxy adhesives necessitate mixing before application, as they comprise resin and hardener.

- They offer exceptional bonding strength across diverse materials, including glass, ceramics, and metals.

- Epoxy’s versatility lies in its ability to resist chemicals, ensuring durable and robust bonds.

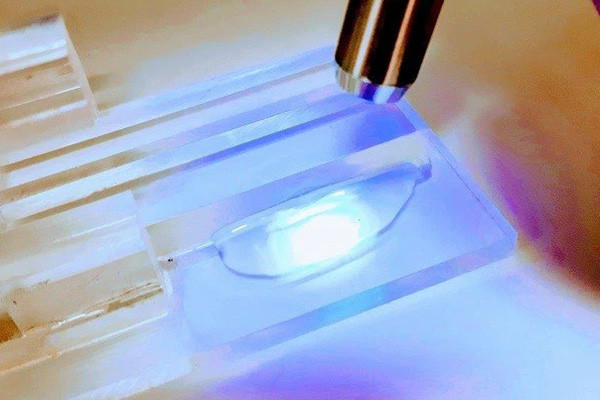

UV Curing Adhesives

- These adhesives solidify when exposed to ultraviolet light, resulting in rapid hardening.

- They’re versatile and known for their clarity and strength, suitable for glass, plastic, and electronics applications.

- It is ideal for precise bonding needs where a clean, rapid bond is essential.

Acrylic Adhesives

- Acrylic adhesives are highly durable on surfaces such as metals, plastics, and glass.

- They offer reliable bonds and are resistant to environmental factors like heat, chemicals, and moisture.

- Available in diverse forms like tapes and liquid adhesives, catering to various application methods.

Silicone Adhesives

- These adhesives excel in flexible bonding across materials like glass, plastics, and metals.

- They are known for resisting extreme temperatures and weather conditions, making them ideal for outdoor applications.

- They are frequently used in sealing due to their water-resistant properties.

Polyurethane Adhesives

- Polyurethane adhesives create strong bonds across various materials, including wood, plastics, and metals.

- Their flexibility makes them suitable for applications that involve movement or stress.

- They’re dependable in various conditions and offer good resistance to water and chemicals.

Each type of transparent adhesive possesses unique characteristics, catering to specific needs based on the materials to be bonded, required strength, environmental conditions, and application methods. Suitable adhesive ensures a reliable and durable bond, which is crucial for various projects and repair works. Understanding these adhesive types allows for informed decisions and successful bonding applications across different industries and personal projects.

How Does Transparent Adhesive Work?

Transparent adhesives are crucial in various industries, offering a seamless bonding solution without compromising visibility. Understanding the underlying science behind these adhesives sheds light on their functionality and the process of creating transparent bonds.

Chemical Composition

- Transparent adhesives often consist of polymers like acrylics or polyurethanes.

- These polymers are formulated to have low levels of color and impurities, ensuring optical clarity.

- Adding additives, such as stabilizers or UV inhibitors, maintains transparency and enhances durability.

Adhesion Mechanism

- The adhesive’s ability to create transparent bonds relies on its molecular structure and surface interaction.

- Surface energy plays a vital role; adhesives with similar surface energies to the bonded materials create stronger bonds.

- The adhesive molecules form intermolecular forces, such as van der Waals forces or hydrogen bonding, with the substrate, leading to adhesion.

Clarity and Refractive Index

- Transparency in adhesives is achieved by closely matching the refractive index of the adhesive to that of the substrate.

- Light passes through without distortion or scattering when the refractive indices align, resulting in a transparent bond.

- The absence of visible air pockets or gaps between the surfaces contributes to optical clarity.

Application and Curing Process

- During application, the adhesive is typically applied thinly and evenly on the surfaces to be bonded.

- The curing process, often activated by factors like heat, light, or moisture, initiates the cross-linking of polymer chains, forming a robust and transparent bond.

- Proper curing conditions and techniques are essential to maintain the adhesive’s transparency and bond strength.

Environmental Factors and Durability

- Environmental factors like temperature, humidity, and exposure to UV light can impact the transparency and longevity of the bond.

- UV inhibitors in the adhesive formulation help prevent yellowing or degradation caused by sunlight exposure.

- Proper surface preparation and selection of suitable adhesive for specific environmental conditions ensure the longevity of transparent bonds.

What Are the Applications of Transparent Adhesive in Construction?

Transparent adhesives are indispensable in modern construction practices, especially where aesthetics and structural integrity converge. These adhesives are pivotal in creating visually stunning and robust constructions, from bonding glass components to assembling transparent plastics, sealing joints, and enhancing facade systems. Their ability to form strong, invisible bonds contributes significantly to transparent materials’ functionality, durability, and aesthetic appeal in construction projects.

Glass Bonding

- Transparent adhesives use extensively in construction for bonding glass components, such as windows, facades, and glass panels.

- These adhesives offer a seamless and nearly invisible bond, enhancing the aesthetics of glass structures.

- Structural glazing systems rely on transparent adhesives to create strong, load-bearing bonds between glass panels, ensuring durability and visual appeal.

Plastic Bonding

- Transparent adhesives are vital in bonding transparent plastics like acrylics, polycarbonates, and PETG.

- They enable the assembly of plastic components, creating visually pleasing and structurally sound constructions.

- Applications range from creating transparent barriers, display cases, to assembling intricate plastic structures in architectural designs.

Sealing and Waterproofing

- Transparent adhesives are effective sealants for transparent construction elements, preventing water infiltration without compromising visibility.

- They seal glass joints, ensuring water-tightness in aquariums, glass roofs, or skylights.

- Waterproofing with transparent adhesives maintains the aesthetic appeal while offering robust protection against moisture ingress.

Facade and Cladding Systems

- Transparent adhesives contribute to installing facade and cladding systems by bonding transparent or translucent materials to building exteriors.

- They enable the seamless attachment of materials like glass, polycarbonate, or composite panels, enhancing the building’s visual appeal.

- These adhesives are critical in providing structural integrity and weather resistance to facade assemblies.

Point Fixing and Glass Assemblies

- Transparent adhesives facilitate the point fixing method, allowing glass panels to be attached to structures with minimal visible hardware.

- They enable the creation of frameless glass assemblies, emphasizing transparency and architectural elegance.

- Often seen in canopies or balustrades, point-fixed glass structures rely on these adhesives for secure bonding and unobstructed views.

Transparent adhesives are indispensable in modern construction practices, especially where aesthetics and structural integrity converge. These adhesives are pivotal in creating visually stunning and robust constructions, from bonding glass components to assembling transparent plastics, sealing joints, and enhancing facade systems. Their ability to form strong, invisible bonds contributes significantly to transparent materials’ functionality, durability, and aesthetic appeal in construction projects.

In What Ways Is Transparent Adhesive Used in Electronics?

Transparent adhesives are indispensable in construction, playing a multifaceted role in electronics, particularly in circuit assembly and screen bonding. Their unique properties enable seamless integration and structural support within electronic devices, fostering durability and functionality.

Circuit Assembly

- Transparent adhesives are utilized in electronics for affixing and bonding delicate electronic components onto circuit boards.

- They offer precision and reliability in securing components without interfering with electrical conductivity.

- These adhesives are crucial in assembling intricate circuits in smartphones, tablets, and computers.

Screen Bonding

- In screen manufacturing, transparent adhesives are crucial for affixing display panels onto electronic devices.

- They ensure a strong, nearly invisible bond between the screen and the device housing, providing structural support while maintaining visual clarity.

- This process is fundamental in producing seamless and durable screens for smartphones, TVs, monitors, and other display devices.

Optical Bonding

- Transparent adhesives are pivotal in optical bonding, enhancing screen visibility and durability in electronic displays.

- By bonding layers of glass or plastic together, these adhesives reduce reflections and increase contrast, improving the overall viewing experience.

- This application is crucial in high-end displays used in industrial equipment, medical devices, and automotive screens.

Heat Dissipation and Protection

- Some transparent adhesives offer properties that aid heat dissipation within electronic devices, ensuring optimal performance.

- They also provide protective coatings, safeguarding electronic components against moisture, dust, and other environmental factors without obstructing visibility.

Microelectronics and Wearable Devices

- Transparent adhesives are instrumental in assembling microelectronic devices, where precision and transparency are paramount.

- They play a role in bonding sensors, microchips, and components in wearable technology, supporting functionality while maintaining a sleek design.

What Advantages Does Transparent Adhesive Offer Over Other Adhesives?

Transparent adhesives stand out among various adhesive options due to their unique advantages, offering a blend of clarity, flexibility, and durability that cater to diverse applications. These adhesives have revolutionized bonding solutions, providing unmatched benefits across multiple industries and settings.

Clarity and Aesthetics

- One of the most significant advantages of transparent adhesives is their ability to create nearly invisible bonds, maintaining the visual integrity of materials.

- They excel in applications where aesthetics are crucial, such as bonding glass, plastics, or transparent substrates, ensuring that the adhesive doesn’t compromise the appearance of the joined materials.

- In construction, electronics, and product design, transparent adhesives elevate the overall visual appeal by seamlessly integrating components without visible bonding lines.

Flexibility and Adaptability

- Transparent adhesives exhibit flexibility, allowing for slight movement or expansion of bonded materials without compromising the bond’s integrity.

- This flexibility is precious in constructions or products subjected to temperature changes, vibrations, or mechanical stress, as it helps prevent cracks or bond failure.

Versatility in Material Compatibility

- These adhesives demonstrate compatibility with a wide range of materials, including glass, plastics, metals, and composites.

- They offer versatility in bonding various substrates, allowing for assembling dissimilar materials while maintaining optical clarity and structural strength.

Durability and Longevity

- Transparent adhesives are engineered to provide robust and durable bonds, ensuring longevity in diverse environmental conditions.

- They resist yellowing or degradation caused by exposure to UV light, making them ideal for outdoor applications, such as construction or automotive uses.

- In electronic devices, these adhesives contribute to the structural integrity of screens and circuit assemblies, enduring constant use and environmental factors without compromising performance.

Enhanced Optical Properties

- Certain transparent adhesives contribute to improved optical properties, reducing reflections or enhancing contrast in displays, thus improving visibility and user experience.

- Optical bonding techniques using these adhesives help eliminate air gaps between layers, minimizing glare and enhancing screen readability.

Ease of Application and Handling

- Transparent adhesives often come in formulations that are easy to apply and handle, whether through dispensing equipment or manual application methods.

- Their ability to cure quickly or adhere at room temperature streamlines manufacturing processes, reducing production time and costs.

Environmental and Health Considerations

- Many transparent adhesives are formulated to meet environmental regulations, offering low VOC (volatile organic compounds) emissions and being non-toxic.

- They contribute to sustainable practices in manufacturing by aligning with eco-friendly standards without compromising performance.

Are There Any Disadvantages or Limitations to Transparent Adhesive?

Transparent adhesive, known for its versatility and clarity, is a popular choice across various industries and applications due to its ability to bond materials seamlessly. However, despite its numerous advantages, this adhesive type also presents limitations and drawbacks that should be considered before use. Understanding these aspects is crucial for informed decision-making when choosing the suitable adhesive for specific purposes.

- UV Sensitivity:One of the primary limitations of transparent adhesive is its susceptibility to ultraviolet (UV) light. Prolonged exposure to UV rays can cause the adhesive to degrade or yellow over time, affecting its clarity and weakening its bonding strength. This limitation might not be suitable for applications involving outdoor or extended sunlight exposure.

- Temperature Sensitivity:Transparent adhesives may exhibit reduced performance in extreme temperatures. In extremely hot or cold conditions, the adhesive’s bonding properties might diminish, leading to weakened adhesion or even complete failure. This limitation can be a concern in environments with significant temperature variations or where the adhesive is subjected to extreme heat or cold.

- Chemical Compatibility:Another consideration is the compatibility of transparent adhesive with certain chemicals or substances. Some adhesives might not resist specific solvents or chemicals, leading to a breakdown in the adhesive properties or affecting the bonded materials. Understanding the chemical compatibility of the adhesive with the intended materials and environments is crucial to prevent potential failures.

- Peel Strength and Durability: While transparent adhesives offer excellent initial bonding strength, their long-term durability might vary. Factors such as surface preparation, application technique, and the type of materials being bonded can affect the adhesive’s peel strength over time. This limitation might impact applications with sustained or high mechanical stress, potentially leading to bond failure.

- Cost Consideration:Transparent adhesives, especially those with specialized formulations for clarity and performance, might be more expensive than other adhesive options. Cost-effectiveness is essential to evaluate, especially for large-scale or repetitive applications, where the adhesive cost could significantly impact the overall budget.

How Do You Apply Transparent Adhesive Correctly?

Correctly applying transparent adhesive is essential for achieving optimal bonding strength and durability in various applications. Whether it’s for DIY projects or industrial uses, understanding the correct application techniques is crucial to ensure a successful bond. From surface preparation to curing methods, following specific steps can significantly impact the effectiveness of transparent adhesive.

Surface Preparation:

- Cleaning: Begin by cleaning the surfaces that will be bonded with the adhesive. Remove any dust, grease, or contaminants using a suitable cleaner or solvent recommended for the materials involved. Proper cleaning ensures better adhesion and prevents potential bond failures.

- Surface Roughening: In some cases, especially with smooth or non-porous surfaces, lightly roughening the surface with sandpaper or similar abrasive material can enhance the adhesive’s grip by providing a better bonding surface.

Application Technique:

- Appropriate Amount: Apply the adhesive in the appropriate amount. Too much adhesive can lead to excess squeeze-out, while too little might result in weak bonds. Follow the manufacturer’s guidelines regarding the recommended quantity for the specific materials being bonded.

- Even Distribution: Ensure the adhesive is spread evenly across the surfaces to be bonded. Use tools like brushes, rollers, or spreaders to achieve uniform coverage, preventing air bubbles and ensuring maximum contact between the adhesive and the materials.

Curing and Setting:

- Time and Temperature: Follow the recommended curing time and temperature specified by the adhesive manufacturer. Allow sufficient time for the adhesive to cure properly, as inadequate curing time can result in weaker bonds. Maintain the recommended temperature range during the curing process for optimal bond strength.

- Clamping or Pressure: In some applications, applying pressure or using clamps to hold the bonded materials together during the curing process can enhance the bond strength. Ensure the pressure is evenly distributed across the bond line without causing damage to the materials.

Post-Application Considerations:

- Cleanup: Promptly clean any excess adhesive that may have squeezed out during the bonding process. Use appropriate solvents or methods recommended by the adhesive manufacturer to remove excess adhesive without damaging the bonded materials.

- Inspection: After the adhesive has fully cured, inspect the bonded area for any defects or irregularities. Ensure the bond is strong and meets the desired specifications for the intended application.

By following these steps and adhering to the specific guidelines provided by the transparent adhesive manufacturer, you can effectively apply the adhesive for optimal bonding results. Proper surface preparation, precise application techniques, and adherence to curing instructions are key factors in achieving strong and durable bonds in various projects and applications.

Can Transparent Adhesive Be Used in Medical Applications?

The use of transparent adhesive in medical applications has gained prominence due to its versatility, non-invasive nature, and compatibility with various healthcare needs. Its applications span medical devices, wound care, and other healthcare-related fields, offering solutions that prioritize patient comfort, durability, and adequate adhesion without causing harm or irritation to the skin or underlying tissues.

Medical Devices:

- Secure Bonding: Transparent adhesive finds extensive use in securing medical devices such as electrodes, sensors, and patches to the skin. Its hypoallergenic properties and gentle adhesion make it suitable for prolonged wear without causing skin irritation or discomfort to patients.

- Flexibility and Comfort: The flexibility of transparent adhesive allows it to conform to body contours, ensuring a comfortable fit for patients while maintaining a solid bond between the medical device and the skin.

Wound Care:

- Transparent Dressings: Transparent adhesive films or dressings are utilized in wound care to create a protective yet breathable barrier over wounds. These dressings facilitate wound healing by providing a moist environment while allowing for visual inspection of the wound without needing removal.

- Gentle Adhesion: The gentle adhesive properties of transparent dressings prevent damage to the wound area upon removal and reduce pain for patients during dressing changes.

Healthcare-Related Fields:

- Surgical Applications: In surgical settings, transparent adhesive tapes or films are employed for securing dressings, tubing, or medical devices during procedures. Their transparency enables monitoring and assessing the skin or wound beneath the dressing without removal.

- Medical Sealants: Transparent adhesive sealants are used in specific medical procedures for their ability to seal and protect incisions or wounds, providing an effective barrier against infection while promoting healing.

What Are Some Environmental Considerations with Transparent Adhesive?

Using transparent adhesive in healthcare and medical applications brings forth various environmental considerations encompassing its manufacturing, disposal, and impact on ecosystems. While transparent adhesive is a valuable tool in medical devices, wound care, and other healthcare-related fields, its environmental implications need assessment to ensure responsible use and minimize potential ecological effects.

Material Composition:

- Chemical Components: Understanding the chemical composition of transparent adhesives is crucial. Some adhesives may contain substances that can pose environmental risks if improperly handled or disposed of. Assessing the presence of potentially hazardous chemicals is essential for minimizing adverse environmental effects.

Manufacturing Processes:

- Resource Consumption: The manufacturing process of transparent adhesive may involve using natural resources, energy, and chemicals. Evaluating the environmental impact of these processes, such as carbon emissions or water usage, aids in selecting adhesives produced through eco-friendly practices or those with reduced ecological footprints.

Disposal and Biodegradability:

- Disposal Methods: Transparent adhesive used in medical applications, such as wound care, raises concerns regarding its disposal. Understanding proper disposal methods, including whether the adhesive is recyclable or requires special handling, is vital to prevent environmental contamination or landfill accumulation.

- Biodegradability: Assessing the biodegradability of transparent adhesive post-use is crucial. Biodegradable adhesives break down naturally over time, reducing their environmental impact compared to non-biodegradable counterparts. Exploring options with higher biodegradability aids in mitigating long-term ecological concerns.

Impact on Ecosystems:

- Ecotoxicity: The potential ecotoxicity of transparent adhesive is a concern, particularly in medical applications where it may come in contact with aquatic environments. Analyzing the impact on marine life and ecosystems due to the leaching of adhesive components or residues is crucial for preserving environmental health.

Sustainability and Alternatives:

- Sustainable Practices: Encouraging the adoption of sustainable practices in adhesive manufacturing, such as using renewable resources or reducing waste generation, minimizes the environmental footprint.

- Exploring Alternatives:Investigating alternative adhesive options with lower environmental impact, such as bio-based adhesives or those derived from natural sources, presents opportunities to promote environmentally friendly choices in healthcare settings.

Are There Special Considerations for Storage and Shelf Life?

By understanding the special storage considerations, ensure that transparent adhesives remain viable and perform when needed. Proper storage, considering factors such as temperature, humidity, exposure to light, and packaging, is essential to maintain these adhesives’ effectiveness and shelf life, preserving their quality and longevity.

Optimal Conditions:

- Temperature Control:Store transparent adhesives within specified temperature ranges recommended by the manufacturer. Extreme temperatures can degrade the adhesive’s performance, leading to changes in viscosity or chemical breakdown. Typically, a relaxed, dry environment is ideal for adhesive storage.

- Humidity Management:Controlling humidity levels is crucial, as excessive moisture can compromise the adhesive’s integrity. Storing adhesives in a low-humidity environment prevents moisture absorption, which might affect their bonding properties.

Light Exposure:

- UV Protection: Transparent adhesives can be sensitive to ultraviolet (UV) light, which can cause degradation over time. Store adhesives in opaque or UV-protected containers to shield them from direct light exposure, preserving their clarity and adhesive strength.

Container Considerations:

- Sealed Packaging: Ensure that adhesive containers are tightly sealed when not in use. Properly sealing containers prevents evaporation, contamination, or exposure to external elements that could compromise the adhesive’s quality.

- Avoid Contamination:Keep storage containers clean and free from residue or contaminants. Any foreign substances that come in contact with the adhesive might alter its properties or cause inconsistencies in bonding.

Handling Guidelines:

- Avoid Freezing: Some transparent adhesives can be sensitive to freezing temperatures, leading to irreversible changes in their chemical composition. Prevent exposure to freezing temperatures during storage or transportation to maintain their effectiveness.

- Rotational Use: Adhere to a “first-in, first-out” practice when using multiple batches or containers of adhesive to ensure the utilization of older batches first. This approach helps prevent the expiration or degradation of adhesives due to prolonged storage.

Monitoring Shelf Life:

- Expiration Dates: Transparent adhesives typically come with specified shelf life recommendations. Regularly check the expiration dates and adhere to them to ensure optimal performance. Using adhesives beyond their recommended shelf life might result in decreased effectiveness.

Proper storage of transparent adhesives is vital to ensure their longevity and maintain their adhesive properties. Adhering to specific storage conditions involving temperature control, humidity management, protection from light exposure, and appropriate container handling safeguards the quality of these adhesives. Monitoring expiration dates and adhering to manufacturer guidelines enables users to maximize transparent adhesive’s shelf life and effectiveness, ensuring reliable performance when applied in various applications.

What Innovations or Developments Are Happening in the Field of Transparent Adhesive?

The field of transparent adhesive continues to witness innovative advancements and developments aimed at enhancing performance, expanding applications, and addressing specific industry needs. These ongoing innovations are revolutionizing the properties and capabilities of transparent adhesives, catering to diverse sectors and driving efficiency in bonding solutions.

Nano-Technology Integration:

Nano-Adhesives: Innovations in nano-technology have led to the development of nano-adhesives with exceptional bonding strength and improved transparency. These adhesives leverage nanomaterials to create more robust and resilient bonds, expanding possibilities in industries requiring superior adhesive performance.

Enhanced Functionality:

- Self-Healing Adhesives:Researchers are exploring self-healing properties in transparent adhesives, enabling them to repair minor damages autonomously. This innovation holds promise in applications with critical longevity and durability, potentially reducing maintenance and replacement needs.

- Innovative Adhesives:Advancements in materials science are paving the way for intelligent adhesives equipped with functionalities such as responsiveness to environmental changes or stimuli. These adhesives adapt their properties based on external factors, offering tailored solutions for specific applications.

Environmental Sustainability:

- Bio-Based Formulations:The focus on eco-friendly solutions has spurred the development of bio-based transparent adhesives derived from renewable sources. These formulations aim to reduce environmental impact and address concerns regarding traditional adhesive manufacturing processes.

- Biodegradable Adhesives:Efforts are underway to create biodegradable transparent adhesives that break down naturally, minimizing environmental footprint and waste accumulation. Such innovations align with sustainability goals across various industries.

Application-Specific Solutions:

- Medical-grade Adhesives:Continuous advancements in transparent adhesives for medical applications are focused on enhancing biocompatibility, skin-friendliness, and longer wear times for medical devices, wound care, and surgical applications. These developments prioritize patient comfort and health outcomes.

- High-Performance Bonding:Innovations cater to industries requiring high-performance bonding solutions in challenging environments, such as automotive, aerospace, and electronics. Transparent adhesives with improved resistance to extreme temperatures, chemicals, and mechanical stresses continuously evolve to meet these demands.

How Can Transparent Adhesive Aid in Automotive Applications?

Transparent adhesive is a valuable component in the automotive industry, offering various assembly, repair, and maintenance applications. Its versatility, durability, and ability to provide strong bonds make it a crucial tool in automotive manufacturing and upkeep facets, contributing to improved vehicle performance, aesthetics, and efficiency.

Assembly:

- Structural Bonding: Transparent adhesive plays a pivotal role in structural bonding within automotive assembly, seamlessly joining diverse materials like metals, plastics, and composites. Its ability to distribute stress evenly across bonded surfaces enhances vehicle rigidity while reducing weight compared to traditional joining methods like welding or riveting.

- Panel Bonding: Automotive body panel bonding using transparent adhesives ensures uniform stress distribution and contributes to the vehicle’s overall structural integrity. This process eliminates the need for mechanical fasteners, reducing weight and enhancing aesthetics by creating sleek, smooth joints.

Repairs and Maintenance:

- Windshield and Glass Repairs: Transparent adhesive, commonly used in windshield and glass repairs, securely bonds glass components to the vehicle body, ensuring safety and structural integrity. Its transparent nature maintains visibility while providing a solid and durable bond.

- Plastic Component Repairs: In repairing plastic components, transparent adhesive is an effective solution, allowing for solid and inconspicuous repairs. It offers a seamless finish, ensuring the rebuilt parts maintain their structural strength.

Specialized Applications:

- Sealing and Gasketing: Transparent adhesives have applications in sealing components and gasketing, providing airtight and watertight seals. Preventing water from entering the vehicle, reducing noise levels, and improving overall vehicle performance are crucial.

- Vibration Dampening: Transparent adhesives also aid in reducing vibrations and noise within the vehicle by bonding components, mitigating unwanted sounds, and enhancing passenger comfort.

What Safety Precautions Should Be Taken When Using Transparent Adhesive?

A versatile bonding agent, transparent adhesive is commonly used in various settings, from crafting to industrial applications. While its transparency and adhesive solid properties make it a valuable tool, ensuring safety during its use is crucial. Several precautions should be taken to safely handle and apply transparent adhesive to prevent accidents or health risks.

Ventilation and Air Circulation

Ensure adequate ventilation in the workspace when using transparent adhesive. Proper air circulation helps disperse potentially harmful fumes emitted during the adhesive’s application. Working in well-ventilated areas or using fans and open windows can minimize exposure to these fumes, reducing health risks associated with inhaling them.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is imperative. Gloves safeguard the skin from direct contact with the adhesive, preventing skin irritation or allergic reactions. Safety glasses or goggles shield the eyes from accidental splashes or spills, averting potential eye irritation or injury.

Handling and Storage

Properly handle and store transparent adhesive according to manufacturer instructions. Ensure the lid or cap is securely closed when not in use to prevent accidental spills or leaks. Store the adhesive in a cool, dry place away from direct sunlight or heat sources, as extreme temperatures might alter its properties.

Avoiding Skin Contact and Inhalation

Minimize skin contact using tools like brushes, spatulas, or applicators when working with transparent adhesive. Refrain from touching the adhesive with bare hands to prevent skin irritation or allergic reactions. Additionally, avoid breathing in vapors by working in a well-ventilated area and positioning oneself away from direct exposure to the adhesive.

Clean-Up and Disposal

After use, promptly clean any spills or excess adhesive using appropriate solvents or cleaning agents suggested by the manufacturer. Dispose of empty containers or unused adhesives following local regulations and guidelines for hazardous waste disposal.

What Are the Differences Between Transparent Adhesive and Regular Glue?

Transparent and regular glue are adhesive substances used in various applications, yet they differ significantly in composition, strength, and preferred use cases. Understanding these distinctions can guide users in selecting the most suitable adhesive for their needs, considering factors like transparency, bonding strength, and intended application.

Composition

Transparent adhesive, often based on cyanoacrylate, boasts a clear, see-through consistency, offering an almost invisible bond after drying. In contrast, regular glue encompasses a broader category, including various types such as polyvinyl acetate (PVA), epoxy, or rubber-based adhesives. Everyday glue may come in multiple colors and opacities, lacking the transparency characteristic of transparent adhesive.

Strength

The transparent adhesive is renowned for its high bonding strength, creating durable bonds on various materials, including plastics, metals, and glass. Its fast-curing properties allow for quick bonding, often within seconds or minutes of application. While available in different strengths depending on its type, regular glue might require longer curing times and offer a different instantaneous bonding level than transparent adhesive.

Specific Use Cases

Transparent adhesive favors applications where an invisible bond is crucial, such as in crafts, jewelry making, or repairing glassware. Its ability to bond fine materials without leaving visible residue makes it ideal for projects requiring aesthetic appeal. With its diverse formulations, regular glue suits various applications, including woodworking, paper crafts, fabric bonding, and general household repairs, offering versatility in bonding multiple materials.

Transparent adhesive and regular glue differ significantly in composition, strength, and specific use cases. While transparent adhesive provides a delicate and robust bond, particularly on fine materials, everyday glue encompasses a broader range of formulations suitable for various applications. Considering the desired transparency, bonding strength, and intended use is crucial in selecting the most appropriate adhesive for any given project or task. These differences empower users to make informed choices, ensuring optimal results and performance based on their specific adhesive needs.

Can Transparent Adhesive Bond Different Types of Materials Together?

Transparent adhesive, with its versatile bonding capabilities, often raises questions about its ability to bond different materials together. Understanding its compatibility with various surfaces is essential to determine its efficacy in joining disparate materials, ranging from plastics to metals or glass.

Plastic to Plastic

Transparent adhesive demonstrates excellent bonding strength when used to combine various plastics. Acceptable adhesive forms strong bonds between polycarbonate, acrylic, PVC, or other plastic derivatives, creating a seamless connection without compromising their transparency.”

Metal to Plastic or Glass

Transparent adhesive also exhibits the ability to bond metals to plastics or glass. While achieving a solid bond between metal and plastic or glass can be challenging due to their differing properties, specific formulations of transparent adhesive, designed explicitly for multi-material bonding, can effectively join these surfaces, offering durability and reliability in the bond.

Glass to Glass or Other Surfaces

One of the notable applications of transparent adhesive lies in bonding glass to glass or other surfaces. Whether it’s repairing glassware, creating artistic glass projects, or affixing glass elements to different materials, the transparent adhesive provides a strong, nearly invisible bond, maintaining the clarity and aesthetic appeal of the glass.

Considerations and Limitations

While transparent adhesive showcases impressive bonding capabilities across various materials, it’s essential to consider factors like surface preparation, cleanliness, and the specific type of adhesive used. Some formulations might not bond certain materials as effectively as others, and surface preparation ensuring surfaces are clean and free of contaminants plays a crucial role in achieving optimal bonding results.

How Does Transparent Adhesive Perform Under Extreme Conditions (Heat, Cold, Moisture)?

The performance of transparent adhesive under extreme conditions, such as exposure to heat, cold, and moisture, is critical in assessing its reliability and durability. Understanding how transparent adhesive withstands these challenging environments helps determine its suitability for various applications, from everyday use to industrial settings where environmental conditions vary significantly.

Heat Resistance

Transparent adhesive often exhibits decent heat resistance, maintaining its bonding strength within a specific temperature range. Depending on the formulation, some transparent adhesives can withstand temperatures ranging from -40 °C to over 120°C, ensuring stability and strength in bonded materials even under moderate heat exposure.

Cold Resistance

In cold environments, the performance of transparent adhesive can vary. While some formulations maintain their bonding strength in low temperatures, others might experience reduced effectiveness. Transparent adhesive typically performs better under cold conditions than regular glue. Still, prolonged exposure to extreme cold might affect its adhesive properties, potentially leading to brittleness or reduced bond strength.

Moisture and Water Resistance

Transparent adhesive often boasts good moisture and water resistance, making it suitable for applications where exposure to humidity or occasional water contact occurs. However, prolonged immersion in water or exposure to high moisture levels might weaken the bond over time, especially if the adhesive is not explicitly formulated for underwater or continuous wet conditions.

Transparent adhesive exhibits varying degrees of performance under extreme conditions like heat, cold, and moisture. While it generally demonstrates decent resistance to moderate temperatures and humidity, its performance can be affected by prolonged exposure to extreme conditions. Choosing the appropriate formulation to withstand specific environmental challenges is crucial for ensuring optimal bonding strength and durability of transparent adhesive in applications where exposure to harsh conditions is anticipated.

What Factors Should Be Considered When Choosing Transparent Adhesive?

Choosing a suitable transparent adhesive involves considering various factors that ensure its effectiveness in different applications. From the nature of the surfaces being bonded to the environmental conditions, each aspect plays a crucial role in determining the suitability of the adhesive. Here are some essential factors to ponder when selecting transparent adhesives:

Factors to Consider When Choosing Transparent Adhesive:

- Substrate Compatibility:Assess the materials you intend to bond. Ensure the adhesive is compatible with both surfaces, considering porosity and chemical composition factors.

- Transparency and Clarity: The primary characteristic of transparent adhesives is their ability to maintain optical clarity. Consider the level of transparency needed for your application, ensuring it doesn’t compromise visual aesthetics.

- Adhesive Strength:Evaluate the required bond strength based on the application. Factors like shear, tensile, and peel strengths should align with the project’s demands to ensure durability and reliability.

- Curing Time: Consider the curing or setting time of the adhesive. Some applications require quick bonding, while others allow longer setting times for precision alignment.

- Environmental Resistance: Assess the ecological conditions the adhesive will endure factors such as temperature, humidity, and exposure to chemicals or UV light can affect adhesive performance.

- Application Method:Determine the ease of application whether via dispensing systems, manual application, or automated processes and choose accordingly based on the project’s requirements.

- Safety and Regulations: Ensure the adhesive complies with safety standards and regulations, particularly concerning toxicity, flammability, and other relevant safety measures.

- Long-Term Stability: Consider the adhesive’s longevity. Will it maintain its properties over time or degrade, affecting the bond’s strength and clarity?

- Cost and Availability:Factor in the adhesive’s cost per unit and availability. Balancing quality with affordability is essential for cost-effective solutions.

Are There DIY Applications for Transparent Adhesive?

Transparent adhesive, prized for its versatility and strong bonding properties, finds a multitude of do-it-yourself (DIY) applications in crafting and home projects. Its clear and nearly invisible bonding makes it a valuable tool for various creative and practical endeavors, offering many possibilities for DIY enthusiasts looking to enhance their projects.

Crafting:

- Jewelry Making:Transparent adhesive is perfect for securely bonding delicate beads, gems, and metals in jewelry crafting, providing a seamless finish without visible residue.

- Paper Crafts:It’s ideal for intricate paper projects like card-making or scrapbooking, allowing precise bonding of paper elements without marring their appearance.

- DIY Decor: Use transparent adhesive to affix decorative elements like sequins, rhinestones, or embellishments onto surfaces like fabric or glass for customized decor items.

Home Repairs:

- Fixing Glassware: Transparent adhesive effectively repairs broken glass items like vases, cups, or ornaments, creating strong, nearly invisible bonds that restore functionality and appearance.

- Plastic Repairs:It’s handy for fixing plastic household items such as toys, containers, or kitchenware, providing a durable and precise bond.

Electronics and Gadgets:

- Device Repair: Use transparent adhesive to repair small electronic components or fix cellphone screens, ensuring a secure and transparent bond without affecting device aesthetics.

- Circuitry and Hobby Electronics:It’s suitable for affixing small components in DIY electronic projects, ensuring a secure connection without obstructing visibility.

Model Making and Hobbies:

- Scale Modeling: Transparent adhesive is invaluable in scale model construction, seamlessly bonding tiny parts like windows or precise components.

- Dioramas and Miniatures:Use it to assemble intricate dioramas or miniature scenes, ensuring solid and inconspicuous bonds between various materials.

Transparent adhesive is a versatile and indispensable tool for DIY enthusiasts, offering many applications in crafting and home projects. Its precise, strong bonding capabilities make it a go-to adhesive for diverse creative endeavors, from crafting jewelry to repairing household items or enhancing hobby projects, allowing individuals to achieve professional-looking results in their DIY ventures.

What Is the Future Outlook for Transparent Adhesive?

The world of adhesives continues to evolve, and transparent adhesives are on a trajectory of significant advancements. The future outlook for transparent adhesives is promising, marked by technological innovations and increasing demand across various industries. Here are some key points that shed light on the anticipated future trends and developments in transparent adhesives:

Future Outlook for Transparent Adhesive:

- Advanced Formulations:Expect continuous research and development to yield adhesives with enhanced properties such as improved strength, greater flexibility, and adaptability to a broader range of substrates.

- Nano and Bio-Based Adhesives:Anticipate the rise of nano-adhesives offering superior bonding at microscopic levels and the advent of bio-based adhesives, aligning with sustainability initiatives, reducing environmental impact, and ensuring biodegradability.

- Innovative Adhesives:The future might witness the integration of intelligent features within adhesives, enabling functionalities like self-healing capabilities, self-monitoring for integrity, and responsiveness to environmental stimuli.

- Industry-Specific Solutions:Expect tailored adhesive solutions catering to specific industries like automotive, electronics, healthcare, and construction, meeting the stringent demands of each sector with precision and efficiency.

- Increased Transparency and Clarity:With a growing emphasis on aesthetics and design, anticipate improvements in transparency and clarity, allowing for seamless bonding in applications where visual appearance is crucial.

- Rapid Cure and Adaptable Application Methods:Future adhesives may offer faster curing times and more versatile application methods, facilitating quicker production processes and improved efficiency.

- Environmentally Conscious Solutions:A shift towards eco-friendly formulations, recyclable materials, and reduced volatile organic compounds (VOCs) aligns with global sustainability goals, driving the development of environmentally conscious adhesive options.

- Integration of Functionalities: Integrating multiple functionalities within a single adhesive such as bonding, sealing, and conducting electricity will likely become more prevalent, enhancing the versatility and utility of transparent adhesives.

Conclusion

The world of transparent adhesives holds boundless possibilities for creative endeavors—their versatility and effectiveness in bonding materials open doors to innovation and unique project outcomes. As you delve into transparent adhesives, consider this a starting point—a catalyst for your exploration. Embrace experimentation, discover new techniques, and push the boundaries of your projects. Embracing the transparency in adhesives might unveil a whole new dimension to your creative pursuits. So, take that leap, delve more deeply, and uncover how these adhesives can elevate your craftsmanship and imagination.

DeepMaterial

Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. More…

UV Curing Adhesives

UV light cure have a number of benefits making them a popular choice among many product assembly and manufacturing applications. Many UV light cure adhesives can provide a nearly instantaneous bond to difficult substrates like glass and plastic. UV cure adhesives often require an accelerator or UV light for a bond to form.

Adhesive Blogs & News

The latest adhesive industry science and technology, Deepmaterial news, and market trends and forecasts.

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy This article systematically expounds the quantitative relationship between the crosslinking density and the flexibility and hardness of adhesives. Combining the theories of polymer physics with experimental analysis methods, it reveals the mechanism of the action of the

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives UV adhesives have been widely used in many fields such as electronics, optics, and medicine due to their advantages of rapid curing, high bonding strength, and environmental protection. However, their rapid curing property also brings challenges in some application scenarios.

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields LED UV glue adhesive has been widely applied in numerous fields due to its advantages such as rapid curing and easy operation. However, in fields with stringent safety requirements like medical and food packaging, its biocompatibility after curing

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions The dispensing process is an important part of the application of LED UV glue adhesive, and the quality of this process directly affects the final performance of the product. The physical properties of the glue,