Protective Film

DeepMaterial is focus on providing adhesive and film application materials products and solutions for communication terminal companies and consumer electronics companies, semiconductor packaging and testing companies, and communication equipment manufacturers.

DeepMaterial functional protective film solutions

Functional protective film solutions can simplify and enhance the efficiency of many manufacturing processes.

In many engineering applications, protective film solutions are now doing jobs that previously required entire assembly components. These multifaceted products often combine several functionalities into a single element.

DeepMaterial supplies functional protective film solutions to guard a wide variety of surfaces, including freshly painted components, throughout your process and all the way to the dealer. These protective films remove cleanly and easily, even after extended exposure to the elements.

Functional protective film features

· Abrasion-resistant

· Chemical-resistant

· Scratch-resistant

· UV-resistant

Therefore, you can simplify your various production processes by opting for multi-functional films. Protective films are the best choice for protecting your product from defects.

Consumer electronics display/screen protectoer

· Abrasion-resistant

· Chemical-resistant

· Scratch-resistant

· UV-resistant

Anti-static Optical Glass Protection Film

The product is a high cleanliness anti-static protective film, the product mechanical properties and size stability, easy to tear off and tear up without leaving residual adhesive. It has good resistance to high temperature and exhaust. Suitable for material transfer, panel protection and other use scenarios.

Optical Glass UV Adhesion Reduction Film

DeepMaterial optical glass UV adhesion reduction film offer low birefringence, high clarity, very good heat and humidity resistance, and a broad range of colors and thicknesses. We also offer anti-glare surfaces and conductive coatings for acrylic laminated filters.

Semiconductor device fabrication begins with the deposition of extremely thin films of material on silicon wafers. These films are deposited one atomic layer at a time using a process called vapor deposition. Accurate measurements of these thin films and the conditions used to create them are becoming evermore critical as semiconductor devices such as those found in computer chips shrink. DeepMaterial partnered with chemical suppliers, deposition process tool manufacturers and others in industry to develop an advanced thin film deposition monitoring and data analysis scheme that provides a much-improved view of the systems and chemicals that form these ultrathin films.

DeepMaterial provides this industry with essential measurement and data tools that help identify optimal manufacturing conditions. Vapor deposition thin film growth depends on controlled delivery of chemical precursors to the silicon wafer surface.

Semiconductor equipment manufacturers use DeepMaterial measurement methods and data analysis to improve their systems for optimal vapor deposition film growth. For example, DeepMaterial developed an optical system that monitors film growth in realtime, with significantly higher sensitivity compared with traditional approaches. With better monitoring systems, semiconductor manufacturers can more confidently explore the use of new chemical precursors and how layers of different films react with each other. The result is better “recipes” for films with the ideal properties.

Semiconductor Packaging & Testing UV Viscosity Reduction Special Film

The product uses PO as the surface protection material, mainly used for QFN cutting, SMD microphone substrate cutting, FR4 substrate cutting (LED).

LED Scribing/Turning Crystal/Reprinting Semiconductor PVC Protective Film

LED Scribing/Turning Crystal/Reprinting Semiconductor PVC Protective Film

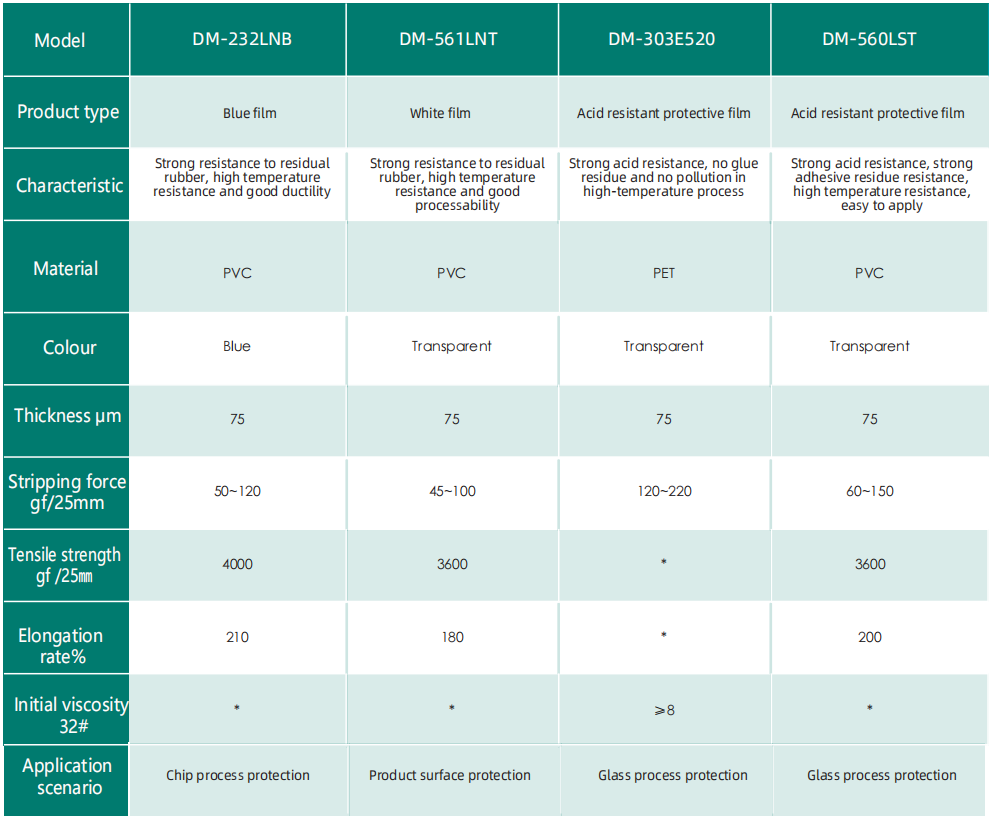

Protective Film Product Selection

| Product Seriess | Product name | Product typical application |

Wafer surface protection

| DM-232LNB | It is a surface protective fifilm material, which is processed with soft PVC fifilm and acrylic adhesive, and can be used for glass, metal and wafer cutting and processing protection. This product adopts special adhesive, which has excellent acid and alkali resistance, strong resistance to residual glue, easy to tear and not easy to break, and excellent oil resistance, heat resistance and drug resistance. |

| DM-561LNT | It is a kind of surface protection fifilm material, which is processed with soft PVC fifilm and acrylic adhesive. It can protect glass, metal and wafer surface in the process. This product uses special adhesive, with excellent processability, strong resistance to residual glue, easy to tear and not easy to break, and excellent oil resistance, heat resistance and drug resistance. | |

Anti-acid protective film

| DM-303E520 | A high cleanliness, transparent, high temperature and acid resistant protective fifilm. The product is evenly coated, has good adsorption, and is easy to peel without residual glue. It is applied to the protection of glass processing. |

| DM-560LST | It is a surface protective fifilm material, which is processed with soft PVC fifilm and acrylic adhesive, and can be used for glass, metal and wafer cutting and processing protection. This product adopts special adhesive, which has excellent acid resistance, strong adhesive residue resistance product series, easy to tear, not easy to break, excellent heat resistance and drug resistance. |

Product Data Sheet of Protective Film