- Home

- >

- Application

- >

- Display Screen Adhesive

Display Screen Adhesive

In today’s tech-dominated landscape, the unsung hero behind seamless device operation is one essential element often overlooked: Display Screen Adhesive. This adhesive, pivotal yet often unnoticed, plays a monumental role in upholding the durability and functionality of screens. As screens evolve and become integral to our daily lives, understanding the intricacies of Display Screen Adhesive becomes imperative. Let’s embark on an enlightening journey to unlock the power and significance of this adhesive, discovering its profound impact on our technological experiences.

Table of Contents

ToggleWhat is Display Screen Adhesive and Why Does it Matter?

Display screen adhesive, or optically clear adhesive (OCA), is a specialized adhesive used to assemble electronic screens. It’s a transparent and often ultra-thin layer that adheres to the different components of a screen, such as the cover glass, touch sensor, and LCD or OLED panel. This adhesive must maintain optical clarity, ensuring it doesn’t obstruct the display quality while securely holding the layers together.

Why Does it Matter?

- Structural Support:Display screen adhesive acts as a cohesive force, binding the various layers of a screen together. This structural support is vital in preventing delamination or separating layers, ensuring the screen functions seamlessly.

- Enhanced Durability:By providing a strong bond between layers, OCA significantly improves the durability of screens. It protects against potential impact damage, reducing the risk of cracks or breakages.

- Optical Clarity:Maintaining optical clarity is crucial for screen quality. The transparency of the adhesive ensures that it doesn’t distort or diminish the display’s visual output.

- Protection from Elements:Display screens encounter various environmental factors like dust, moisture, and temperature changes. The adhesive acts as a barrier, shielding the sensitive electronic components from these elements, thereby prolonging the screen’s lifespan.

- Touch Sensitivity:In touch-enabled screens, OCA plays a role in preserving the responsiveness and accuracy of touch inputs. It ensures the touch sensor remains closely integrated with the display, maintaining precise functionality.

Applications Across Devices

Display screen adhesive is ubiquitous across a spectrum of devices:

- Smartphones: Essential for holding together the layers of the phone’s display, ensuring both functionality and sleek design.

- Laptops and Tablets: Maintains the integrity of screens in portable devices, withstanding frequent handling and transportation.

- Large Displays and TVs:Even in larger screens, OCA is critical for maintaining picture quality and preventing damage from external factors.

How Does Display Screen Adhesive Ensure Bonding Perfection?

In essence, the display screen adhesive is an unsung technological hero. Its significance extends beyond mere adhesion; it’s a linchpin for the structural integrity, visual quality, and durability of devices we rely on daily.

Here’s a closer look at how to display screen adhesive guarantees bonding perfection:

Precision Engineering

- Display screen adhesive is formulated precisely to adhere to various screen materials, such as glass or plastic, with impeccable accuracy.

- Its composition accounts for thermal expansions and contractions, maintaining integrity under varying temperature conditions.

Seamless Bonding

- The adhesive’s microscopic-level properties allow it to fill in minuscule gaps between the display screen and its casing, facilitating a snug fit.

- This seamless bonding eradicates air pockets, reducing the likelihood of dust accumulation or moisture ingress, which could compromise the screen’s clarity.

Enhanced Durability

- Display screen adhesive isn’t just about adhesion; it’s about fortifying the screen structure. It acts as a shock absorber, mitigating the impact of accidental drops or jolts.

- This adhesive also shields the screen from vibrations and structural stress, elevating the device’s overall durability.

Optical Clarity

- Often engineered to be optically transparent, the adhesive maintains the screen’s visual transparency, preserving the crispness and vibrancy of displayed content.

- Its minimal reflection properties ensure that the user’s viewing experience remains uncompromised.

Longevity and Reliability

- The quality of the display screen adhesive directly correlates with the device’s longevity. High-quality adhesives resist degradation over time, ensuring a reliable bond throughout the device’s lifecycle.

- As a result, users experience fewer issues such as screen lifting, delamination, or deterioration, which commonly occur with inferior adhesives.

Manufacturing Efficiency

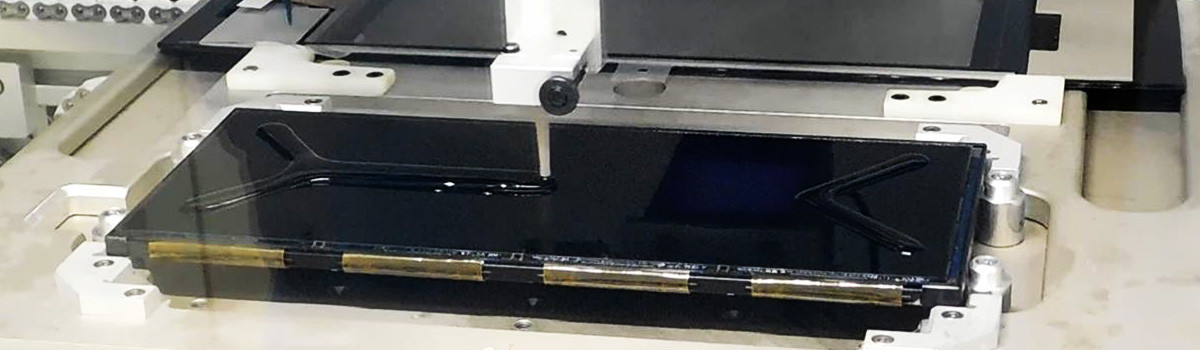

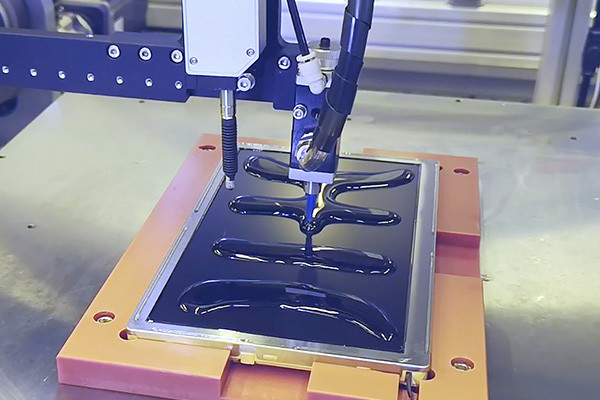

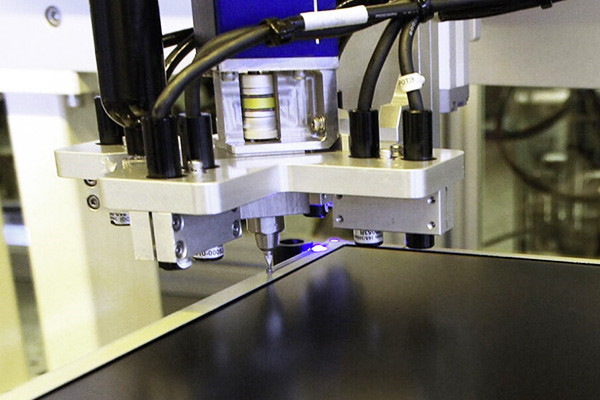

- When formulated for efficient application, display screen adhesive streamlines the manufacturing process, reducing assembly time and increasing production yields.

- Its compatibility with automated application methods optimizes efficiency and consistency in mass production.

Are there different types of display screen adhesives? How can they be compared in a comparative analysis?

In the world of technology, display screens are omnipresent, from smartphones to TVs, laptops to tablets. Behind these sleek screens lies a crucial element often overlooked: the adhesive that bonds the display components. Display screen adhesives are pivotal in ensuring structural integrity, functionality, and visual quality. Understanding the various types can significantly impact device performance and longevity.

Here’s a comparative analysis of different types of display screen adhesives:

Optical Clear Adhesives (OCA)

- Functionality:OCA adhesives are optically transparent, ensuring minimal interference with display clarity.

- Application:They are commonly used in touchscreens and LCD panels because of their ability to reduce reflection and enhance image quality.

- Benefits:Provides a seamless touch experience and improves overall display aesthetics.

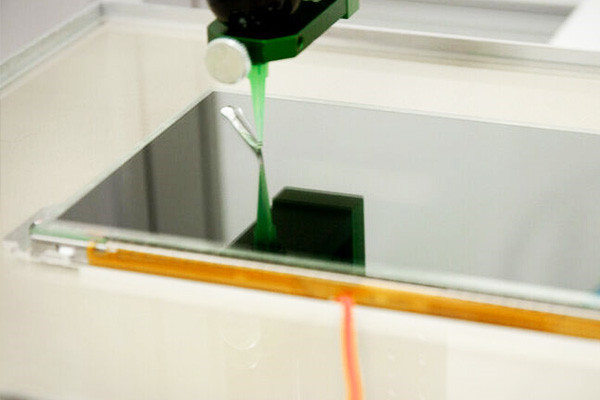

Liquid Optically Clear Adhesives (LOCA)

- Functionality:These liquid-based adhesives solidify under UV light, forming a robust and evident bond.

- Application: Predominantly used in smartphone screens to bond the digitizer to the cover lens, offering durability and touch sensitivity.

- Benefits: Excellent for curved displays and offers improved impact resistance.

Structural Adhesives

- Functionality:These adhesives, known for their strength and durability, provide structural support to the display assembly.

- Application:These materials are used in large displays like TVs and monitors to stabilize and withstand mechanical stress.

- Benefits:Ensures long-term bonding and rigidity, crucial for more extensive and heavier screens.

Pressure-Sensitive Adhesives (PSA)

- Functionality: These adhesives bond on applying pressure and are removable without leaving residue.

- Application:Ideal for temporary bonding, screen protectors, and films where repositioning is necessary.

- Benefits:They offer easy application, reusability, and minimal damage during removal.

Comparative Factors

- Transparency:OCAs and LOCAs excel in optical clarity, which is ideal for maintaining screen visibility.

- Strength and Durability:Structural adhesives outperform in providing long-term support, especially for larger screens.

- Flexibility:LOCAs offer flexibility for curved displays, while PSAs allow repositioning.

- Specialized Applications:Each adhesive type suits specific device requirements, ensuring optimal performance.

Innovations in Display Screen Adhesive Technology: What’s Next?

Innovations in display screen adhesive technology are pivotal in driving the evolution of modern screens. From nanotechnology to eco-friendly formulations and self-healing capabilities, the future holds promising advancements. As demands for thinner, more durable, and versatile displays increase, display screen adhesives will continue to be instrumental in shaping the next generation of visual technology.

Advancements Driving Change

- Nanotechnology Integration:Nano-scale adhesives are revolutionizing display screen technology, offering superior bonding at a microscopic level. These adhesives enhance screen resilience and enable slimmer, more lightweight designs.

- Flexible Substrates:Adhesives tailored for flexible screens enable bendable and foldable displays. With improved flexibility, screens can withstand repeated bending without compromising performance.

- High Thermal Conductivity: Advanced adhesives with enhanced thermal conductivity efficiently dissipate heat from screens, preventing overheating issues. This innovation ensures a prolonged screen lifespan, especially in high-performance devices.

Trends Reshaping the Industry

- Optical Clarity Enhancement:Adhesives with improved optical properties enhance display clarity, reducing distortion and enhancing user experience, crucial for augmented reality (AR) and virtual reality (VR) applications.

- Environmentally Conscious Formulations:The industry is shifting towards eco-friendly adhesive formulations. Manufacturers are exploring bio-based and recyclable materials, reducing environmental impact without compromising performance.

- Self-Healing Adhesives:Innovations in self-healing adhesives are on the horizon. These adhesives can autonomously repair minor scratches or damages on display screens, ensuring prolonged usability and aesthetics.

Future Projections and Challenges

- Microscopic Bonding:Advancements aim to refine adhesive application techniques to achieve stronger and more precise bonding at a microscopic level, leading to even thinner and lighter screens.

- Durability and Longevity:The quest for adhesives that offer unparalleled durability and longevity remains a primary focus. Future formulations aim to withstand extreme conditions while maintaining optimal performance.

- Integration with Emerging Technologies:As technology converges, display screen adhesives will integrate with emerging tech like foldable displays, transparent screens, and wearable devices, presenting unique adhesive challenges and opportunities.

How to Choose the Right Display Screen Adhesive for Your Device?

Selecting the appropriate display screen adhesive is critical to ensure your device’s longevity, performance, and reliability. Making the right choice can be overwhelming with an array of adhesives available. Here’s a guide to help you navigate through the selection process effectively:

Consider Your Device and Screen Type

- Screen Material:Determine the material of your display screen (e.g., glass, plastic, OLED). Different adhesives are designed for specific screen materials to ensure optimal bonding without causing damage.

- Flexibility Requirements:If your device incorporates flexible or curved screens, opt for adhesives explicitly formulated for flexibility to prevent cracking or detachment during use.

Assess Environmental Factors

- Temperature and Humidity Resistance:Consider the environmental conditions your device will encounter. Adhesives with high-temperature resistance are crucial for devices exposed to heat, while moisture-resistant adhesives are vital in humid environments.

- Chemical Resistance:Evaluate if your device will be exposed to chemicals or solvents. Select adhesives that offer resistance against these substances to maintain adhesive integrity.

Performance Specifications

- Adhesive Strength:Assess the required bond strength based on the size and weight of the screen. High bond strength is essential for more extensive displays or devices subjected to constant movement or stress.

- Optical Clarity:For displays requiring impeccable clarity, opt for adhesives with excellent optical properties to prevent distortion or haziness.

Application and Installation Considerations

- Curing Time:Consider the time needed for the adhesive to set completely. Some applications require quick-curing adhesives for faster production processes.

- Ease of Application:Evaluate the application method and ensure compatibility with your manufacturing process. Some adhesives come in specific forms like tapes, films, or liquids, each with its application requirements.

Compliance and Safety Standards

- Regulatory Compliance:Ensure the selected adhesive complies with industry standards and regulations regarding safety, environmental impact, and product quality.

- Health and Safety:Consider adhesives that emit low volatile organic compounds (VOCs) to maintain a safe working environment during application.

Consultation and Testing

- Expert Advice:When you’re uncertain, it’s helpful to consider consulting adhesive specialists or manufacturers for recommendations tailored to meet your device’s specific requirements.

- Sample Testing:Conduct small-scale tests using samples of different adhesives to assess compatibility and performance before full-scale implementation.

DIY Screen Repair: Can Display Screen Adhesive Save the Day?

In a world where our daily lives revolve around screens, encountering a cracked or damaged display can feel like a technological crisis. A shattered screen can disrupt productivity, communication, and entertainment, whether it’s a smartphone, tablet, laptop, or any other device. Enter display screen adhesive a potential savior for DIY enthusiasts aiming to mend their damaged screens without breaking the bank.

The Challenge of Screen Damage

Screen damage is a common woe for gadget users. Dropping a device or applying excessive pressure can lead to cracks, scratches, or shattered displays. Professional repairs often come with hefty price tags, prompting many to explore alternative solutions. Display screen adhesive is a plausible option for those who venture into DIY repairs.

Understanding Display Screen Adhesive

Display screen adhesive is a specialized glue designed to bond shattered screens, securing loose components without compromising visibility or touchscreen functionality. It offers a viable solution for minor cracks or shattered displays, provided the damage doesn’t interfere with the underlying technology.

Pros of Using Display Screen Adhesive

- Cost-effective: Repairing a screen using adhesive is significantly cheaper than opting for professional services or purchasing a new device.

- Accessibility:Display screen adhesives are readily available in the market, often coming in kits that include the necessary tools for application.

- DIY-Friendly: Applying display screen adhesive can be a feasible DIY project with proper instructions and patience.

- Versatility:Adhesive solutions cater to various screen types, from smartphones to laptops, making them a versatile option for multiple devices.

Caveats and Considerations

While display screen adhesive presents an appealing DIY solution, it’s essential to acknowledge its limitations and potential risks:

- Skill Requirement:Precise application is crucial. DIY repairs demand steady hands and attention to detail.

- Compatibility:Not all screen damages are fixable with adhesive. Severe cracks or damage to the underlying technology might require professional intervention.

- Voiding Warranties:Attempting a DIY repair could void warranties or insurance policies on the device.

- Risk of Further Damage:Mishandling adhesive or incorrect application may exacerbate the damage.

Does display screen adhesive have an impact on display quality?

While the impact of display screen adhesive might seem subtle, its significance cannot be overstated. Manufacturers continually strive to optimize this crucial component to deliver superior display quality to consumers.

Let’s delve deeper into this critical element to understand its impact on the visual experience:

- Adhesive Composition:Display screen adhesive is engineered to bond layers within the display stack, securing components like the glass, touch panel, and backlight. Silicones, acrylics, or specialized bonding materials are commonly used.

- Visual Clarity:The adhesive’s transparency and refractive index significantly affect how light passes through the layers. An adhesive with optimal transparency ensures minimal distortion and clear, sharp visuals.

- Color Accuracy:The color reproduction on a screen can be altered if the adhesive material interacts unfavorably with the display components. High-quality adhesive minimizes color distortion, preserving accurate color representation.

- Durability and Longevity:Adhesive quality directly impacts the durability of the display. A robust adhesive withstands temperature changes, moisture, and mechanical stress, ensuring the display’s longevity.

- Touch Sensitivity:In touch-enabled displays, the adhesive layer influences touch responsiveness. A well-engineered adhesive maintains optimal touch sensitivity without compromising its bonding properties.

- Reduction of Optical Anomalies:Inferior adhesive materials may introduce optical anomalies like glare, reflection, or halo effects, detracting from the viewing experience. Premium adhesives mitigate these issues.

- Manufacturing Precision:The application process of the adhesive demands precision. Any irregularities during application can lead to air bubbles or uneven bonding, affecting display uniformity.

- Repair and Maintenance:The adhesive quality used during initial assembly can also impact repair processes. A poorly bonded display might complicate repair attempts or reduce the effectiveness of repairs.

Environmental Considerations: Are Display Screen Adhesives Eco-Friendly?

In pursuing technological advancement, the world is increasingly aware of the environmental impact of every component within our devices. Among these often-overlooked elements, display screen adhesives play a significant role in determining the quality of our screens and their eco-friendliness.

Let’s explore the environmental considerations associated with display screen adhesives:

- Material Composition:Traditionally, display screen adhesives encompassed materials that posed environmental concerns due to their chemical composition. However, a shift towards eco-friendly alternatives is underway. Silicones, acrylics, and bio-based materials are being explored to minimize environmental impact.

- Toxicity and Emissions:Conventional adhesives might release harmful volatile organic compounds (VOCs) during manufacturing and usage, contributing to air pollution. Eco-friendly adhesives aim to reduce or eliminate VOC emissions, prioritizing human health and environmental safety.

- Recyclability and Disposal:Disposing of electronic devices and their components poses a significant environmental challenge. Eco-friendly adhesives allow for easier separation of components during recycling and can reduce electronic waste, promoting a circular economy.

- Renewable and Sustainable Sources:Manufacturers increasingly source adhesive materials from renewable and sustainable sources. Bio-based adhesives derived from plant-based or recycled materials reduce reliance on non-renewable resources.

- Energy Consumption:Producing display screen adhesive often involves significant energy consumption. Innovations focus on reducing the energy footprint through more efficient manufacturing techniques.

- Regulatory Compliance:Adhesive manufacturers are subject to environmental regulations and certifications. Adhering to stringent standards ensures compliance with eco-friendly practices and encourages continuous improvement in sustainability.

- Lifecycle Assessment:Assessing the complete lifecycle of display screen adhesives helps identify areas for improvement. From raw material extraction to disposal, analyzing each stage enables a more holistic approach to reducing environmental impact.

The drive towards eco-friendly display screen adhesives aligns with the growing consumer demand for sustainable technology. Manufacturers are increasingly investing in research and development to create adhesives that meet performance criteria and uphold environmental responsibility.

What are the challenges in display screen adhesive applications? Is there a troubleshooting guide available?

In the dynamic world of technology, display screens play a pivotal role in various devices, from smartphones to large-scale monitors. Ensuring their seamless functionality involves intricate details, one critical element being the adhesive that holds these screens in place. However, this seemingly simple component can pose several challenges in display screen applications, demanding meticulous troubleshooting for effective resolution.

Challenges in Display Screen Adhesive Applications

Adhesive Compatibility

- Different screen types require specific adhesives, necessitating precise compatibility.

- The diverse range of screen materials, including glass, plastic, or OLED, requires customized adhesive solutions to suit their characteristics and needs.

Environmental Factors

- Temperature variations during application affect adhesive properties and bonding strength.

- Humidity levels impact curing time, potentially leading to suboptimal bonding.

Application Technique

- Inaccurate application techniques might result in uneven adhesive distribution, affecting screen integrity.

- Improper handling can introduce air bubbles or dust particles, compromising display clarity.

Bonding Strength and Durability

- Adhesive failure due to inadequate bonding strength leads to screen detachment.

- Longevity and resilience of the adhesive under stress or impacts are crucial for sustained performance.

Troubleshooting Guide for Display Screen Adhesive Applications

Adhesive Selection

- Research and ensure the compatibility of the adhesive with screen materials.

- Consult manufacturers’ guidelines or experts for suitable adhesive recommendations.

Environmental Controls

- Maintain optimal temperature and humidity conditions during application and curing.

- Use controlled environments or specialized equipment to mitigate environmental effects.

Precision in Application

- Follow precise application guidelines provided by adhesive manufacturers.

- Utilize tools like rollers or templates for even adhesive distribution and bubble prevention.

Quality Assurance

- Conduct thorough inspections pre and post-application for any defects or irregularities.

- Perform stress tests to evaluate the bonding strength and durability of the adhesive.

Remedial Actions

- In case of bonding issues, identify the root cause and address it promptly.

- Consider reapplication or using supplementary adhesives as per expert recommendations.

Display Screen Adhesive in Smartphones: A Critical Component?

In the intricate world of smartphone design and functionality, a critical yet often overlooked hero is the display screen adhesive. This tiny, unassuming component plays a pivotal role in our beloved handheld devices’ seamless operation and structural integrity. Let’s dive deeper into this unsung hero and explore its significance:

The Backbone of Display Assembly

- Display screen adhesive is the binding agent that holds together the various layers of a smartphone’s display assembly.

- It secures the delicate components, including the touch-sensitive panel, digitizer, LCD or OLED screen, and protective glass, ensuring they function harmoniously.

Structural Support and Durability

- Beyond mere adhesion, this adhesive provides structural support, preventing the display layers from separating and safeguarding against potential damage from impacts and external pressures.

- It contributes significantly to the device’s durability and longevity, crucial in an era where smartphones endure constant handling and occasional drops.

Optical Clarity and User Experience

- The adhesive material’s quality directly impacts the display’s visual clarity. A well-chosen adhesive maintains optical transparency, ensuring a crisp and vibrant screen display.

- It influences the user experience by enabling smooth touch responsiveness and minimizing interference between layers, enhancing the overall usability of the device.

Technological Advancements

- With advancements in smartphone technology, the demands on display screen adhesive have intensified. Thinner and more flexible screens require adhesives that can withstand bending without compromising functionality.

- Innovations in adhesive materials aim to strike a delicate balance between flexibility, durability, and optical clarity, pushing the boundaries of what’s possible in display technology.

Challenges and Innovations

- Adhesive failure or degradation can lead to display malfunctions or visual defects. Manufacturers constantly face the challenge of selecting adhesives that endure various environmental conditions and usage patterns.

- Research and development efforts focus on creating adhesives that offer stronger bonds, improved resistance to temperature changes, and better compatibility with evolving display technologies.

What is the chemistry behind display screen adhesives? How can we break it down?

Display screen adhesives serve multifaceted purposes, including bonding layers within the screen assembly, reinforcing structural stability, and shielding against external elements. The chemistry behind these adhesives is a fusion of precision and innovation, often leveraging a combination of materials and compounds for optimal performance.

Core Components

- Acrylic Polymers:Acrylic-based adhesives are frequently utilized for their versatility and robust bonding properties. These polymers offer excellent adhesion to various substrates and maintain stability across multiple temperatures.

- Polyurethane Resins:Polyurethane resins contribute to the adhesive’s ability to withstand mechanical stress and environmental factors, ensuring the screen’s durability through their resilience and flexibility.

- Silicone Compounds:Silicone-based adhesives offer superior thermal conductivity and shock absorption, safeguarding the delicate electronic components within the display.

The Chemical Reactions

The chemistry of display screen adhesives involves complex reactions that occur during the curing process:

- Polymerization:Acrylic polymers undergo polymerization when exposed to specific curing agents or UV light, forming molecular solid bonds.

- Cross-Linking:Polyurethane resins undergo cross-linking, wherein molecular chains interconnect, enhancing the adhesive’s strength and flexibility.

- Condensation Reactions:During curing, silicone compounds undergo condensation reactions that form a stable network structure, enhancing their ability to dissipate heat and provide mechanical cushioning.

Breaking Down the Chemistry

Understanding the chemistry of display screen adhesives involves dissecting their molecular compositions and reaction mechanisms:

- Identifying Components:Analyzing the adhesive’s ingredients and their respective roles elucidates its functionality.

- Examining Curing Methods:Exploring various curing techniques, thermal, UV, or moisture-curing, reveals how specific reactions take place under different conditions.

- Testing Performance:Evaluating the adhesive’s performance under stress, temperature variations, and environmental exposure helps comprehend its chemical resilience.

Durability Testing: How Reliable is Your Display Screen Adhesive?

In today’s tech-driven world, display screens are integral in various devices, from smartphones and tablets to TVs and laptops. Ensuring the reliability of these screens involves meticulous attention to detail, particularly regarding the adhesive that holds them together. The durability of display screen adhesive is a critical factor determining the longevity and quality of these devices.

Understanding Display Screen Adhesive

- Display screen adhesive is the binding force between layers, securing the delicate components in place.

- It’s engineered to withstand various stresses, including temperature changes, pressure, and environmental factors.

- The adhesive’s properties directly impact the screen’s ability to resist cracks, moisture, and detachment.

Importance of Durability Testing

Durability testing is the litmus test for display screen adhesive reliability. It involves subjecting the screens to rigorous conditions to simulate real-world scenarios. Here’s why it’s crucial:

- Assessing Longevity: Durability tests evaluate how well the adhesive holds up, ensuring the screen remains intact throughout the device’s lifespan.

- Quality Assurance:Manufacturers utilize rigorous testing to identify potential weak points, enabling them to refine and improve adhesive formulations, ultimately enhancing their performance.

- Performance Verification:Testing validates whether the adhesive meets industry standards and specifications, ensuring it performs reliably under diverse conditions.

Factors Impacting Durability

Several key elements influence the reliability of display screen adhesive during durability testing:

- Temperature Extremes:Adhesives must endure high and low temperatures without losing their adhesive properties.

- Mechanical Stress:The adhesive should withstand physical impacts and flexing without compromising its integrity.

- Chemical Resistance:Resistance to chemicals and moisture is vital to prevent degradation over time.

Future Innovations and Challenges

As technology evolves, the demand for more durable and resilient adhesives increases. Innovations focus on enhancing adhesive strength while maintaining flexibility, enabling thinner and lighter screens without sacrificing durability. Challenges, however, persist:

- Miniaturization:As devices become smaller and sleeker, engineers face the challenge of maintaining adhesive strength in tighter spaces.

- Environmental Impact:Balancing durability with environmentally friendly materials remains challenging in adhesive development.

What do you need to know about display screen adhesive and its heat resistance?

Display screen adhesive plays a pivotal yet often overlooked role in the assembly of electronic devices. Its significance lies in securing delicate components like screens, ensuring durability and functionality. Heat resistance is a key factor influencing performance and longevity among its critical attributes.

Here’s what you need to know about display screen adhesive and its heat resistance:

Purpose of Display Screen Adhesive

- Vital in securing display screens onto electronic devices.

- Ensures proper bonding between various layers without compromising visual quality or touch sensitivity.

Composition and Properties

- Typically made of specialized materials like acrylics or silicones.

- Adhesives are designed to withstand environmental factors such as moisture, dust, and temperature variations.

- Variations in viscosity and curing time cater to different application requirements.

Heat Resistance

- The crucial factor determining the adhesive’s performance under varying temperatures.

- High heat resistance ensures the adhesive maintains its integrity and bond strength, even in elevated temperatures.

- Protects the display screen from damage due to excessive heat, preventing delamination or detachment.

Factors Affecting Heat Resistance

- Chemical composition:Some adhesives are inherently more heat-resistant due to their formulation.

- Thickness and application technique: Proper application and thickness impact the adhesive’s ability to withstand heat.

- Quality of materials:High-quality adhesives designed explicitly for electronic screens enhance heat resistance.

Applications and Industries

- Widely utilized in manufacturing smartphones, tablets, laptops, and various electronic displays.

- Automotive industry: Used in-vehicle infotainment systems and dashboard displays.

- Medical devices and industrial equipment also rely on display screen adhesive for secure assembly.

Importance of Heat Resistance

- It prevents screen detachment or damage, particularly in high-temperature environments.

- This process ensures the consistent performance and reliability of electronic devices.

- Enhances the device’s longevity by maintaining the display assembly’s structural integrity.

Future Innovations and Advancements

- Ongoing research focuses on developing adhesives with even higher heat resistance.

- Innovations target eco-friendly formulations and improved bonding properties.

What are the case studies showcasing successful stories of effective display screen adhesive usage?

Display screen adhesive has revolutionized the way electronic devices are assembled and maintained. Its versatile applications and adhesive solid properties have led to numerous success stories in the industry. Case studies highlighting the practical usage of display screen adhesive underscore its importance in enhancing device performance and durability.

Here are a few compelling case studies that showcase the successful utilization of display screen adhesive:

Mobile Devices Industry

Case Study: Smartphone Waterproofing

- Display screen adhesive played a pivotal role in sealing smartphone screens, making them water-resistant without compromising touch sensitivity. This innovative usage enhanced the durability of smartphones, reducing water-related damages and increasing customer satisfaction.

Automotive Sector

Case Study: In-Car Display Panels

- Adhesive technology was instrumental in affixing display screens within car dashboards, ensuring secure placement even under varying temperature and vibration conditions. As a result of these improvements, long-lasting and reliable display panels were achieved, enhancing both the driving experience and safety features.

Medical Equipment Manufacturing

Case Study: Medical Monitors

- Display screen adhesive was utilized in assembling critical medical monitors, ensuring a secure bond between the screens and housing. The advancements made in this field contributed to the reliability and accuracy of these devices, which are crucial in medical diagnostics and patient care.

Consumer Electronics

Case Study: Tablet and Laptop Assembly

- Adhesive technology enabled thin, lightweight displays to be securely fixed within tablets and laptops, maintaining structural integrity while enhancing portability. This usage led to sleeker designs without compromising device durability.

Industrial Displays and Machinery

Case Study: Industrial Control Panels

- Display screen adhesive played a vital role in constructing rugged industrial control panels. These panels endured harsh environmental conditions, such as extreme temperatures and vibrations, ensuring uninterrupted operation in industrial settings.

These case studies highlight the transformative impact of display screen adhesive across diverse industries. The adhesive’s ability to securely bond screens while withstanding environmental challenges has significantly contributed to product reliability, customer satisfaction, and technological advancements.

What are the common misconceptions about display screen adhesive that have been debunked?

Display screen adhesive is a crucial component in technology, ensuring screens remain intact and functional. However, several misconceptions surrounding this adhesive have been debunked through careful analysis and advancements in technology.

Let’s unravel these misconceptions:

Permanent Damage to Screens

- Debunked:One of the prevalent myths is that display screen adhesive causes irreversible damage to screens during application or removal.

- Truth:Modern adhesive formulas are designed to be non-destructive. They adhere firmly but can be removed without leaving residue or causing harm to the screen when done correctly.

Incompatibility with Screen Types

- Debunked:Many believe that display screen adhesive is only suitable for specific screen types.

- Truth: Advanced adhesives cater to various screen materials, including glass, plastic, and OLED, ensuring compatibility across different devices without compromising functionality or appearance.

Compromised Screen Sensitivity

- Debunked:A common misconception is that applying adhesive affects the touch sensitivity of screens.

- Truth:High-quality adhesives maintain the screen’s sensitivity, ensuring seamless touch response without compromising performance.

Limited Durability

- Debunked:Some assume that screen adhesives have a short lifespan, requiring frequent replacements.

- Truth:Modern adhesives are engineered for durability, providing long-lasting bonds that withstand daily use and environmental factors, reducing the need for frequent replacements.

Complexity in Application

- Debunked:Many believe that applying screen adhesive is complicated and intricate.

- Truth:While precision is crucial, advancements have simplified the application process with user-friendly kits and detailed instructions, making it accessible for DIY repairs while ensuring adequate bonding.

Adverse Effects on Screen Clarity

- Debunked:There’s a misconception that adhesives may impact screen clarity or create air bubbles.

- Truth: Quality adhesives are formulated to maintain optical clarity and prevent air bubbles, preserving the screen’s visual integrity and ensuring a seamless viewing experience.

Irreversibility of Adhesion

- Debunked:Some believe that the adhesive cannot be reversed or readjusted once applied.

- Truth:Certain adhesives can be repositioned during application, enabling adjustments to achieve the perfect alignment before the bond fully sets.

What does the historical perspective reveal about the evolution of display screen adhesive?

In the digital age, where screens dominate our daily lives, the evolution of display screen adhesive might not be the most apparent narrative. However, delving into its historical journey unveils a fascinating tale of innovation, precision, and technological advancement.

Origins

- Display screen adhesive finds its roots in the early developments of display technologies.

- Initially, screens relied on mechanical fastenings or cumbersome adhesives that lacked the finesse needed for delicate screens.

- Early adhesives were often messy, prone to failure, and inadequate for the demands of emerging display technologies.

Innovations Driving Change

- Transitioning from bulky CRT monitors to sleeker LCD and LED screens necessitated adhesive advancements.

- Scientists and engineers focused on creating adhesives that offered robust bonding while being non-intrusive and adaptable to various screen types.

- Silicone-based adhesives emerged as game-changers, providing the flexibility and durability required for modern displays.

Technological Leap

- The evolution of display screen adhesive paralleled the technological leaps in screen manufacturing.

- With the advent of touchscreen devices, the demand for adhesives that facilitated sensitivity while maintaining structural integrity skyrocketed.

- Nano-adhesives entered the scene, allowing for minute bonding at the molecular level, enhancing both functionality and aesthetics.

Precision and Specialization

- As screens diversify in size and composition, adhesives transform to meet specific requirements.

- Ultra-thin screens demanded adhesives that provided strong bonding without adding bulk.

- Specialized adhesives resistant to heat, moisture, and environmental factors became crucial for outdoor displays and rugged devices.

Current Innovations and Future Prospects

- Today, the focus is not just on bonding screens but also on enhancing user experience and sustainability.

- Adhesives with self-healing properties are being explored to address minor damages and prolong screen life.

- Bio-based adhesives and eco-friendly alternatives are gaining traction, aligning with the global push for sustainable technologies.

How can one navigate the world of display screen adhesive compliance amidst regulations and standards?

In the ever-evolving landscape of technology, display screens have become integral in our daily lives, from smartphones to TVs and beyond. However, behind the vivid displays and seamless touch experiences lies a crucial component often overlooked: display screen adhesive. Understanding its compliance with regulations and standards is paramount in ensuring product safety, performance, and environmental responsibility.

Regulatory Landscape

- RoHS Directive (Restriction of Hazardous Substances): This EU directive restricts hazardous electrical and electronic equipment materials, including display screen adhesives. Compliance involves determining substances like lead, mercury, cadmium, and more.

- REACH Regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals): Within the EU, REACH governs the use of chemicals in products. Adhesive manufacturers must comply with hazardous substance restrictions and report the usage of certain chemicals.

- UL Standards (Underwriters Laboratories): UL evaluates products for safety and performance. Display screen adhesive manufacturers can seek UL certification to ensure their products meet safety standards.

Navigating Compliance

- Material Composition Analysis:Manufacturers must conduct thorough analyses of adhesive compositions to ensure they meet regulatory requirements. It involves identifying and limiting substances restricted by various directives and regulations.

- Testing Protocols:Rigorous testing protocols are crucial. Manufacturers must perform tests for substance presence, durability, and environmental impact to ensure compliance with regulations like RoHS and REACH.

- Certifications and Documentation:Seek certifications from reputable bodies like UL and maintain detailed documentation of compliance measures undertaken during adhesive production. This documentation serves as evidence of adherence to standards.

Challenges and Solutions

- Complex Supply Chains:Adhesive manufacturers often source materials globally, leading to complex supply chains. Implementing strict supplier guidelines and regular audits can ensure compliance throughout the chain.

- Constantly Evolving Standards:Regulatory standards are subject to updates and changes. Staying abreast of these changes through continuous monitoring and industry collaborations is essential to ensure ongoing compliance.

Environmental Responsibility

- Circular Economy Initiatives:Embrace eco-friendly practices by developing adhesives that support recycling and sustainable disposal methods, contributing to a circular economy approach.

- Reducing Environmental Impact: Minimize the use of hazardous substances and promote biodegradable alternatives to mitigate the environmental impact of display screen adhesive.

What tips can help prolong the screen lifespan through display screen adhesive maintenance?

Before delving into maintenance tips, understanding the significance of display screen adhesive is vital. This adhesive is responsible for holding the various layers of the screen together, ensuring structural integrity, and preventing delamination.

Tips for Effective Maintenance:

Cleanliness is Key

- Regularly clean the screen using a soft, lint-free cloth. Remove dust, fingerprints, and other particles potentially interfering with the adhesive’s effectiveness.

- Avoid using harsh chemicals or abrasive materials during cleaning, as these can damage the adhesive or the screen.

Avoid Extreme Temperatures

- Keep your devices within optimal temperature ranges. Extreme heat or cold can affect the adhesive’s properties, leading to its deterioration and potential screen detachment.

- Avoid leaving devices in direct sunlight or excessively cold environments for prolonged periods.

Handle with Care

- Be gentle when handling devices with display screens. Rough handling can compromise the adhesive, leading to loosening or detachment of the screen layers.

- Use protective cases or covers to minimize the risk of physical damage that can impact the adhesive’s effectiveness.

Prompt Repairs

- Address any screen damage or detachment issues promptly. Ignoring minor problems can exacerbate the situation, leading to more significant damage and adhesive failure.

- Seek professional assistance for repairs to ensure proper handling and maintenance of the adhesive.

Avoid Moisture Exposure

- Prevent exposure to moisture or liquids as they can seep into the screen layers, affecting the adhesive’s bonding properties.

- In case of accidental spills, immediately power off the device and seek professional help to prevent further damage.

Regular Inspection

- Periodically inspect the screen for any wear, detachment, or bubbles. Early detection of issues allows for timely intervention and prevents further damage to the adhesive.

What role does display screen adhesive play in touchscreen technology?

In essence, while display screen adhesive might seem inconspicuous, its role is pivotal in elevating the performance and durability of touchscreen technology. Advancements in adhesive materials and application techniques continue to refine the user experience, pushing the boundaries of what touchscreens can achieve.

Structural Integrity

- Display screen adhesive acts as the invisible bond that holds together various layers of a touchscreen panel, ensuring structural stability.

- It secures the delicate layers of glass, touch sensors, protective coatings, and display components into a cohesive unit, safeguarding against disintegration.

Sensitivity Enhancement

- The adhesive layer influences the touchscreen’s responsiveness, which affects the touch sensitivity.

- Precision in the application of adhesive helps maintain the sensitivity of the touch panel, enabling accurate and smooth user interactions.

Optical Clarity

- The quality of display screen adhesive directly impacts the clarity of the screen.

- High-quality adhesive minimizes air gaps between layers, enhancing optical clarity and reducing distortions for a clearer display.

Durability and Protection

- Beyond bonding, it serves as a shield, protecting the delicate components from environmental factors like moisture, dust, and shocks.

- A properly applied adhesive layer ensures durability, safeguarding against wear and tear and contributing to the device’s longevity.

Manufacturing Precision

- During manufacturing, the precise application of display screen adhesive is crucial.

- Advanced techniques ensure uniform distribution and thickness of adhesive, contributing to the consistency and quality of the touchscreen.

Customization and Innovation

- Adhesive technology continues to evolve, offering opportunities for customization and innovation in touchscreen design.

- Manufacturers experiment with different adhesives to improve performance, enable flexible displays, and explore new form factors.

What are the unconventional applications of display screen adhesive beyond screens?

Display screen adhesive, typically associated with screen repairs and installations, possesses an array of unconventional applications that transcend the realm of screens. This adhesive, designed for precision and durability, unveils its potential beyond its conventional use. Let’s explore the surprising and innovative applications of display screen adhesive:

Artistic Innovation

- When mixed with pigments or dyes, screen adhesive transforms into a versatile medium for captivating artwork.

- Artists use it to create stunning textures and layers in mixed media art, adding depth and dimension to their pieces.

Industrial Bonding

- Display screen adhesive’s robust bonding properties make it an excellent choice for industrial applications.

- Industries employ it for bonding materials in manufacturing, enhancing structural integrity and durability.

Medical Advancements

- This adhesive finds a niche in the medical field, aiding in developing advanced medical devices.

- It assembles intricate medical equipment, ensuring secure and sterile bonds critical for functionality.

Automotive Excellence

- Within the automotive industry, display screen adhesive plays a pivotal role in vehicle assembly.

- It facilitates the installation of screens and electronic components in cars, ensuring secure placements and longevity.

Aeronautical Applications

- Aerospace engineers leverage display screen adhesive’s reliability for building and repairing aircraft components.

- It contributes to lightweight yet durable constructions vital for the aviation industry.

Fashion and Textiles

- Surprisingly, display screen adhesive has made its way into fashion and textiles.

- Designers utilize its adhesive properties in creating innovative fabric textures or bonding unconventional materials in clothing.

Environmental Solutions

- As sustainability becomes paramount, display screen adhesive finds a purpose in eco-friendly initiatives.

- It aids in repairing and refurbishing electronic devices, extending their lifespan and reducing electronic waste.

Construction Innovations

- In construction, this adhesive isn’t limited to screens but is a reliable bonding agent for various materials.

- It contributes to assembling structures, offering strong adhesion for diverse building components.

Sports Equipment Enhancement

- Manufacturers use display screen adhesive to reinforce and repair sports equipment.

- It ensures the longevity and safety of items like racquets, bats, and protective gear.

Conclusion

In conclusion, the world of display screen adhesive is vast and dynamic, influencing the core of our technological experiences. From the basics of bonding to futuristic innovations, this guide has unveiled the crucial role of display screen adhesives in shaping the devices we rely on daily. As technology evolves, so does choosing the suitable adhesive for optimal performance and longevity. With this knowledge, readers can make informed decisions, ensuring that the bond between screens and adhesives remains unbreakable.

DeepMaterial

Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. More…

UV Curing Adhesives

UV light cure have a number of benefits making them a popular choice among many product assembly and manufacturing applications. Many UV light cure adhesives can provide a nearly instantaneous bond to difficult substrates like glass and plastic. UV cure adhesives often require an accelerator or UV light for a bond to form.

Adhesive Blogs & News

The latest adhesive industry science and technology, Deepmaterial news, and market trends and forecasts.

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy This article systematically expounds the quantitative relationship between the crosslinking density and the flexibility and hardness of adhesives. Combining the theories of polymer physics with experimental analysis methods, it reveals the mechanism of the action of the

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives UV adhesives have been widely used in many fields such as electronics, optics, and medicine due to their advantages of rapid curing, high bonding strength, and environmental protection. However, their rapid curing property also brings challenges in some application scenarios.

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields LED UV glue adhesive has been widely applied in numerous fields due to its advantages such as rapid curing and easy operation. However, in fields with stringent safety requirements like medical and food packaging, its biocompatibility after curing

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions The dispensing process is an important part of the application of LED UV glue adhesive, and the quality of this process directly affects the final performance of the product. The physical properties of the glue,