- Home

- >

- Application

- >

- Electronic Cigarette Adhesive

Electronic Cigarette Adhesive

The spotlight rarely shines on a silent yet pivotal player in electronic cigarettes: the Electronic Cigarette Adhesive. While e-cigarettes capture attention for their components, this unsung adhesive quietly holds everything together. Its role isn’t merely structural. It’s intertwined with safety and functionality. Understanding the nuances of these adhesives is a gateway to unlocking the safety concerns and impacts on vaping devices, urging a closer examination for both users and industry players.

Table of Contents

ToggleWhat is Electronic Cigarette Adhesive?

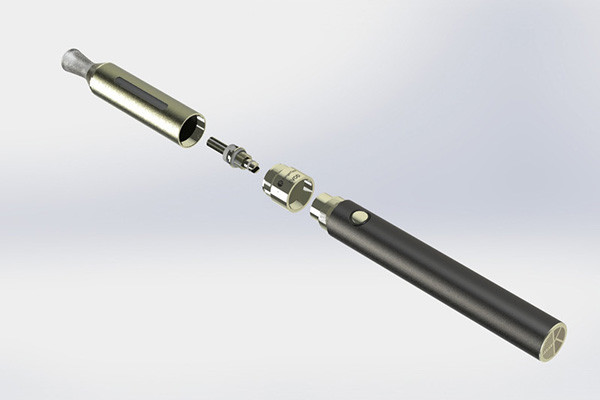

Electronic cigarettes, commonly known as e-cigarettes, have revolutionized smoking habits globally. However, the functionality of these devices relies on a crucial component often overlooked: electronic cigarette adhesive. This adhesive plays a pivotal role in maintaining the structural integrity of e-cigarettes, ensuring their proper functioning and safety.

Understanding Electronic Cigarette Adhesive

- Composition:Electronic cigarette adhesive typically comprises specialized compounds that withstand varying temperatures and pressures. Silicone-based adhesives are frequently used due to their resilience and resistance to heat.

- Purpose:The adhesive serves multiple purposes within an e-cigarette. It secures components together, such as the battery, heating element, and cartridge, ensuring they remain in place during use.

- Heat Resistance:E-cigarettes generate heat during operation, especially at the heating coil. The adhesive’s heat-resistant properties prevent detachment or degradation of essential parts, contributing to the device’s longevity.

- Sealant:The adhesive serves beyond structural support; it acts as a sealant, preventing leaks and ensuring airtightness in critical areas. Avoiding exposure to harmful substances or potential malfunctions due to fluid leakage is crucial.

Importance in E-Cigarette Manufacturing

- Quality Assurance:Manufacturers prioritize high-quality adhesive to maintain the reliability and safety of their e-cigarettes. Substandard adhesive could compromise the device’s functionality and pose potential user risks.

- Safety Compliance:Adhesive materials must comply with safety regulations to ensure that the final product meets industry standards and does not pose health hazards to consumers.

- Innovation and Research:Continuous research focuses on developing advanced adhesive solutions that enhance e-cigarette performance, durability, and safety standards.

Impact on User Experience and Safety

- Reliability:Well-designed adhesive contributes to a reliable e-cigarette experience by minimizing the chances of malfunctions or component detachment during usage.

- Safety:Properly applied adhesive prevents leaks or exposure to hazardous substances, ensuring a safer vaping experience for users.

- Longevity:Quality adhesive prolongs the lifespan of e-cigarettes by maintaining the integrity of internal components, reducing the need for frequent replacements.

How crucial is Adhesive in E-Cigarette Manufacturing?

Electronic cigarettes have revolutionized the smoking experience for millions worldwide, offering a safer alternative to traditional cigarettes. However, behind the sleek designs and innovative technology lies a crucial component often overlooked: electronic cigarette adhesive. This adhesive plays a pivotal role in the manufacturing process and the overall functionality of these devices.

Here’s why electronic cigarette adhesive is indispensable in the manufacturing of these modern smoking devices:

Assembly Precision

- Adhesives are instrumental in securely joining various e-cigarette components, ensuring assembly precision. From bonding the battery to the housing to securing the circuitry, the adhesive forms a strong, reliable bond that withstands regular usage.

Sealing and Protection

- E-cigarette adhesives provide sealing capabilities, safeguarding internal components from external elements such as moisture and dust. This protection is vital in maintaining the device’s performance and longevity.

Thermal Management

- Adhesives with thermal conductive properties assist in managing heat generated within the device. They facilitate heat dissipation from critical components, preventing overheating and potential malfunctions.

Battery Stability

- Ensuring the stability and secure attachment of the battery is paramount in e-cigarette manufacturing. Adhesives are crucial in firmly securing the battery, reducing the risk of displacement or damage during use.

Enhanced Durability

- The right adhesive choice significantly contributes to the durability of electronic cigarettes. It allows the device to withstand constant handling, temperature changes, and other environmental factors without compromising its structural integrity.

Regulatory Compliance

- Adhesives used in e-cigarette manufacturing must comply with stringent safety and material composition regulations. Manufacturers must ensure that the adhesive used meets all required standards for consumer safety.

Overall Performance

- Ultimately, the adhesive’s quality directly impacts the electronic cigarette’s overall performance. A well-chosen adhesive enhances the device’s reliability, functionality, and user experience.

What types of Adhesives are Used in E-Cigarettes?

Electronic cigarettes have revolutionized the smoking industry, offering a cleaner and often considered safer alternative to traditional cigarettes. However, behind their sleek exteriors lies a complex assembly of components, and one crucial yet often overlooked element is the adhesive that holds these parts together. Adhesives play a pivotal role in the construction of e-cigarettes, ensuring their structural integrity, safety, and functionality. Let’s delve into the types of adhesives used in these devices:

Epoxy Resins

- Commonly employed due to their exceptional bonding strength and resistance to heat and chemicals.

- Used to secure various components like the battery, heating element, and circuitry in place.

Cyanoacrylate Adhesives

- They are known for their fast-curing properties and strong bond formation.

- Often utilized in attaching smaller parts or sealing connections within the e-cigarette.

Silicone Adhesives

- Highly flexible and resistant to extreme temperatures.

- Employed in sealing and insulating electronic components to prevent leakage or short-circuiting.

Acrylic Adhesives

- Provide a balance of strength and versatility, suitable for bonding different materials.

- Used in securing the casing and other external components of e-cigarettes.

Polyurethane Adhesives

- Offer excellent durability and resistance to environmental factors.

- Applied in assembling parts that require a robust and long-lasting bond.

Functions of these Adhesives

Bonding and Assembly

- Adhesives serve as the binding force, securely attaching the diverse components of e-cigarettes, ensuring they stay intact during use.

Sealing and Protection

- They create a barrier against moisture, preventing liquid or vapor leakage that could damage sensitive electronic parts.

Thermal Management

- Certain adhesives play a role in aiding heat dissipation, thereby safeguarding the device from overheating and maintaining optimal performance.

Safety and Reliability

- By providing stability and reinforcement, adhesives contribute to the overall safety and reliability of the e-cigarette, reducing the risk of malfunctions or accidents.

Are there Specific Safety Concerns with E-Cigarette Adhesives?

Electronic cigarette adhesives play a crucial role in assembling the various components of e-cigarettes, including the battery, cartridge, and heating element. These adhesives are responsible for securing parts and ensuring the device functions properly. However, questions have arisen about the safety of these adhesives and their potential impact on users.

Safety Concerns

Chemical Composition

- Electronic cigarette adhesives may contain various chemicals to strengthen components’ bonds. Concerns arise when these chemicals are potentially harmful or toxic.

- Some adhesives may release volatile organic compounds (VOCs) when heated, leading to health implications for users.

Heating Element Interaction

- E-cigarettes operate by heating a liquid solution to produce vapor. Adhesives near the heating element may be subjected to high temperatures, raising questions about their stability and potentially releasing harmful substances.

Inhalation Risks

- Users inhale the vapor e-cigarettes produce, and any substances released from adhesives during heating could be inhaled into the lungs.

- The long-term effects of inhaling adhesive-related compounds are not well-studied, prompting concerns about respiratory health.

Quality Control and Manufacturing Standards

- The need for standardized regulations in the manufacturing of e-cigarettes raises concerns about the quality control of adhesives used in their production.

- Inconsistent manufacturing practices may result in variations in adhesive composition and quality.

Addressing Safety Concerns

Research and Regulation:

- Further research is needed to assess electronic cigarette adhesives’ safety and potential health impacts.

- Regulatory bodies should consider establishing guidelines and standards for using adhesives in e-cigarette manufacturing.

Consumer Awareness

- Educating consumers about the potential risks associated with electronic cigarette adhesives is essential.

- Increased awareness can empower users to make informed decisions about their choice of e-cigarettes.

How does Adhesive Impact the Performance of E-Cigarettes?

Electronic cigarettes, also known as e-cigarettes, have revolutionized the smoking landscape, offering an alternative to traditional tobacco consumption. While their functionality relies on various components like batteries, heating elements, and e-liquid cartridges, the adhesive that holds these parts together is an often overlooked yet critical element in their construction. The quality and effectiveness of the electronic cigarette adhesive play a significant role in these devices’ overall performance and safety.

Key Points

- Structural Integrity:Electronic cigarettes comprise multiple parts that must be securely assembled. Adhesives are the binding agent, ensuring these components stay intact and functional. A high-quality adhesive prevents leaks and ensures airtight seals, which is crucial for the proper functioning of e-cigarettes.

- Heat Resistance:E-cigarettes operate by heating the e-liquid to create vapor. Adhesives used in these devices must exhibit exceptional heat resistance to withstand the temperature fluctuations without degrading. Heat-resistant adhesives maintain the structural integrity of the device, preventing any malfunction due to adhesive failure.

- Chemical Compatibility:E-liquids contain various chemicals, including flavorings, nicotine, propylene glycol, or vegetable glycerin. Adhesives in e-cigarettes must be chemically compatible with these substances to prevent any adverse reactions that could compromise the device’s performance or pose health risks to users.

- Safety and Reliability:A reliable adhesive ensures that the different parts of the e-cigarette remain securely attached, reducing the risk of accidental disassembly or malfunction. This reliability contributes to the device’s safety, preventing potential user hazards.

- Longevity and Durability:High-quality adhesives contribute to the longevity of e-cigarettes by providing a durable bond between components. A well-constructed device with a robust adhesive ensures a longer lifespan, providing users with a more reliable and cost-effective product.

- User Experience:The performance of an e-cigarette is directly linked to the quality of its adhesive. A well-designed device with a dependable adhesive enhances the user experience by ensuring consistent functionality, minimal maintenance, and fewer chances of leaks or failures.

Can Adhesive Impact the Safety of E-Cigarettes?

In electronic cigarettes, the discussion often revolves around battery safety, e-liquid ingredients, and device design. However, an element that significantly impacts the safety of these devices yet remains understated is the electronic cigarette adhesive. Understanding how adhesive choices can affect the safety of e-cigarettes is crucial in ensuring a reliable and secure vaping experience.

Key Points

- Seal Integrity:Adhesives play a pivotal role in maintaining the seal integrity of an e-cigarette. A secure seal prevents leakage of e-liquids and ensures that the device functions properly without any spillage, thereby minimizing potential hazards such as exposure to nicotine or other harmful substances.

- Heat Resistance:E-cigarettes operate at elevated temperatures to vaporize the e-liquid. Adhesives used in these devices must exhibit high heat resistance to withstand the thermal stress without degradation. Failure of adhesive under heat can lead to device malfunctions or even accidents, posing safety risks to users.

- Avoiding Chemical Interactions:Certain chemicals in e-liquids can react with subpar adhesives, leading to deterioration of the adhesive material or releasing toxic fumes. Using chemically compatible adhesives with e-liquid components is crucial to prevent potential health hazards or device malfunction due to chemical reactions.

- Preventing Device Failures:Adhesive failure can disintegrate device components. Such separation could result in the vital parts, such as the battery or heating element, being potentially compromised, leading to short circuits, fires, or other safety hazards for users.

- User Handling:E-cigarettes are frequently carried and may be subject to mild impacts or pressure. An adhesive’s strength and reliability ensure that the device remains structurally sound, reducing the likelihood of accidental breakage or damage that could pose safety risks.

- Regulatory Compliance:Adhesives used in e-cigarettes must adhere to safety standards and regulations to ensure that the materials used in these devices do not pose risks to users’ health. Manufacturers must prioritize using adhesives that meet or exceed safety guidelines.

What Makes a High-Quality E-Cigarette Adhesive?

Electronic cigarettes have revolutionized smoking habits, offering a cleaner and potentially safer alternative to traditional cigarettes. Behind the scenes of these devices lies a crucial component that often goes unnoticed but plays a pivotal role: the electronic cigarette adhesive. A high-quality adhesive is imperative for these modern smoking devices’ durability, safety, and overall performance.

Here are the key factors that contribute to making a high-quality electronic cigarette adhesive:

- Heat Resistance:E-cigarettes operate at elevated temperatures, demanding adhesives that can withstand heat without deteriorating or releasing harmful substances. A superior adhesive maintains its integrity even under high temperatures, ensuring the structural stability of the device.

- Chemical Stability:The composition of e-cigarette liquids containing various chemicals and flavors can vary widely. A top-tier adhesive must resist chemical degradation, preventing any interaction between the adhesive and the e-liquid components, which could compromise safety or alter the vaping experience.

- Bond Strength:The adhesive’s ability to create a strong bond between different e-cigarette components is critical. A robust bond ensures the device remains intact, preventing leaks and ensuring consistent performance.

- Non-Toxicity:Safety is paramount in e-cigarette manufacturing. A high-quality adhesive is non-toxic, ensuring it does not release harmful substances or fumes when heated, safeguarding the users’ health.

- Durability and Longevity:E-cigarettes are designed for prolonged use. An adhesive that maintains its strength and adhesive properties over time contributes to the device’s durability, reducing the need for frequent repairs or replacements.

- Compatibility with Materials:E-cigarettes often contain diverse materials such as plastics, metals, and ceramics. A superior adhesive should exhibit compatibility with these materials, ensuring a secure bond without causing any damage or alteration to the components.

- Manufacturing Standards:Following strict manufacturing standards and quality control processes is crucial. A reputable manufacturer ensures that the adhesive meets industry standards and undergoes rigorous testing for reliability and safety.

Are there Regulations Governing E-Cigarette Adhesives?

E-cigarettes consist of various parts, including batteries, cartridges, and heating elements, all held together by adhesives. These adhesives play a vital role in ensuring the structural integrity and safety of the device.

Regulatory Oversight

Surprisingly, no specific regulation currently governs the use of adhesives in e-cigarettes. While regulatory bodies like the FDA (Food and Drug Administration) oversee certain aspects of e-cigarette manufacturing, more explicit directives must be given concerning the adhesives used.

Potential Concerns

The absence of specific regulations raises concerns about the safety and quality of adhesives employed in e-cigarettes. Manufacturers may use different types of adhesives, and without clear guidelines, substandard or potentially hazardous adhesives can be utilized.

Industry Standards and Self-Regulation

Without strict governmental oversight, some manufacturers adhere to industry standards and self-regulation. Reputable companies often prioritize safety and quality, choosing adhesives that meet specific standards even if not explicitly mandated by regulations.

Calls for Regulatory Action

Public health and safety advocates have called for regulatory action to address this gap. They argue that explicit regulations on e-cigarette adhesives are crucial to ensure consistency, security, and quality across all products in the market.

Moving Forward

Regulatory bodies must consider specific guidelines for adhesives used in e-cigarettes to enhance consumer safety and confidence in these devices. Comprehensive regulations would establish standards, testing procedures, and material restrictions, promoting safe and reliable adhesives.

How does Adhesive Impact the Longevity of E-Cigarettes?

Electronic cigarettes, or e-cigarettes, have become increasingly popular as a modern alternative to traditional smoking. The electronic cigarette adhesive is one crucial yet overlooked component contributing to their longevity and performance. This adhesive plays a significant role in these devices’ structural integrity and functionality, impacting their lifespan and user experience.

Importance of Electronic Cigarette Adhesive

- Structural Integrity:Adhesive compounds are essential for holding together various components of an e-cigarette, such as the battery, heating element, and cartridge. A strong adhesive ensures these parts remain securely attached, preventing potential malfunctions or breakdowns.

- Sealing and Insulation:Adhesives create seals that protect sensitive electronic components from moisture, dust, and other environmental factors. Proper sealing prevents damage and ensures consistent performance over time.

- Heat Resistance:E-cigarettes generate heat during operation. Adhesive materials with high heat resistance help maintain the device’s stability and prevent the detachment of crucial parts, enhancing safety and longevity.

- Prevention of Leaks:Adhesive plays a critical role in sealing the connections between elements, including the tank or cartridge. Properly applied adhesive prevents leaks, preserving the device’s integrity and the vaping experience’s quality.

Impact on Longevity

- Enhanced Durability:A well-designed adhesive significantly extends the lifespan of an e-cigarette by providing stability and preventing component detachment, reducing the need for frequent replacements.

- Consistent Performance:Adhesives maintain the structural integrity of the device, ensuring consistent functionality over time. This reliability is essential for a satisfying vaping experience.

- Safety Assurance:High-quality adhesives contribute to the safety of e-cigarettes by preventing potential hazards such as short circuits or component failures, promoting user confidence and trust in the product.

Choosing the Right Adhesive

- Quality Standards:Opt for e-cigarettes that utilize adhesives, meeting stringent quality and safety standards. It ensures reliability and minimizes risks associated with subpar materials.

- Manufacturer Reputation:Consider products from reputable manufacturers known for their attention to detail in selecting adhesives. Established brands often prioritize quality to maintain their reputation.

- User Maintenance:While adhesive quality is crucial, proper care and maintenance by users, such as avoiding exposure to extreme temperatures or excessive force, also contribute to the longevity of e-cigarettes.

What are the Common Issues with E-Cigarette Adhesives?

E-cigarettes, hailed for their potential as a less harmful alternative to traditional smoking, rely on various components to function effectively. One crucial yet often overlooked element is the adhesive that holds these devices together. However, despite their importance, electronic cigarette adhesives can pose various issues that impact the device’s performance and user experience.

Here are some common issues associated with e-cigarette adhesives:

Temperature Sensitivity

- Adhesives used in e-cigarettes can be sensitive to temperature changes, leading to weakened bonds or even detachment of components in extreme conditions.

- Excessive heat from prolonged use or exposure to high external temperatures can compromise the adhesive’s effectiveness, causing parts to loosen or separate.

Chemical Reactivity

- E-cigarette adhesives might react with the e-liquid or other substances used in the device, altering their properties and potentially leading to adhesive degradation.

- Chemical reactions between the adhesive and components of the e-liquid may weaken the bond, affecting the device’s structural integrity over time.

Moisture and Humidity

- Moisture and high humidity levels can negatively impact certain adhesives, causing them to lose their adhesive properties and weaken bonds.

- Exposure to moisture can lead to corrosion or rust of metallic parts within the e-cigarette, exacerbating the adhesive’s deterioration.

Inadequate Bonding Strength

- Some adhesives used in e-cigarettes may have insufficient bonding strength, resulting in loose or detached parts during regular usage.

- Weak bonding can lead to malfunctioning devices, compromising user safety and usability.

Long-Term Durability

- Over time, continuous use and exposure to various environmental factors can deteriorate the adhesive’s durability, reducing its effectiveness in holding the device components together.

Long-term durability issues can result in frequent repairs or replacements, causing inconvenience and added user expenses.

Can Adhesive Influence E-Cigarette Performance in Different Environments?

In the world of electronic cigarettes, the role of adhesive might seem inconspicuous, yet it significantly impacts the overall performance of these devices. The adhesive used in constructing an e-cigarette is crucial in maintaining structural integrity, ensuring proper insulation, and withstanding various environmental conditions. The question arises: Can adhesive influence e-cigarette performance in different environments? Let’s delve deeper.

Adhesive and E-Cigarette Construction

- Structural Integrity:Adhesive secures the components of an e-cigarette, ensuring they remain intact during use and transportation.

- Heat Resistance:In the face of high temperatures generated during vaping, the adhesive’s heat resistance prevents the device from malfunctioning or breaking down.

- Sealing and Insulation:Adhesive seals electronic connections and insulates sensitive components, safeguarding against leaks and short circuits.

Environmental Impact on Adhesive

- Temperature Extremes:Extreme temperatures can affect the adhesive’s properties, potentially leading to weakened bonds or structural issues.

- Humidity:Moisture can compromise adhesive integrity, causing it to degrade and impacting device performance.

- Chemical Exposure:Contact with certain environmental chemicals may deteriorate the adhesive, affecting its ability to hold components together effectively.

Influence on Performance

- Battery Life:A well-chosen adhesive that withstands environmental factors can contribute to prolonged battery life by ensuring proper insulation and protection.

- Vapor Production:Adhesive integrity plays a role in maintaining airtight seals, which is crucial for optimal vapor production.

- Device Durability:Adhesive resilience directly impacts the overall durability of an e-cigarette, affecting its lifespan and reliability.

Adaptive Adhesive Solutions

Manufacturers are continually exploring and employing advanced adhesive technologies to combat environmental challenges. These solutions aim to enhance the following:

- Temperature Tolerance:Adhesives designed to withstand a broad range of temperatures, ensuring consistent performance.

- Moisture Resistance:Waterproof or moisture-resistant adhesives prevent degradation due to humidity.

- Chemical Stability:Adhesives that resist chemical exposure preserve their bonding strength.

Are There Sustainable Alternatives to Traditional E-Cigarette Adhesives?

In electronic cigarettes, adhesive materials are crucial in holding together various components, ensuring functionality and safety. However, the environmental impact of traditional e-cigarette adhesives raises concerns. With an increasing focus on sustainability, researchers and manufacturers are delving into alternative materials that offer both efficacy and eco-friendliness.

Here’s an insightful look at whether sustainable alternatives exist for traditional e-cigarette adhesives:

Challenges Posed by Traditional Adhesives

- Toxicity Concerns:Conventional adhesives used in e-cigarettes often contain chemicals harmful to the environment and human health.

- Disposal Issues:Improper disposal of e-cigarettes with non-biodegradable adhesives contributes to environmental pollution.

- Manufacturing Processes:The production of traditional adhesives may involve energy-intensive processes, further impacting the environment.

Exploring Sustainable Options

- Biodegradable Adhesives:Researchers are exploring bio-based adhesives derived from natural sources like plant-based materials or biopolymers. These materials offer biodegradability, reducing the ecological footprint.

- Water-Based Adhesives: Water-based adhesives, typically composed of renewable resources, show promise in e-cigarette manufacturing. They are non-toxic, emit fewer volatile organic compounds (VOCs), and can enhance recyclability.

- Natural Resins:Some companies are experimenting with adhesives derived from natural resins like rosin, which are renewable and biodegradable.

Benefits of Sustainable Alternatives

- Environmental Impact:Sustainable adhesives contribute to reducing pollution levels and limit the carbon footprint associated with e-cigarette production and disposal.

- Health Considerations:Non-toxic, eco-friendly adhesives diminish the risk of exposure to harmful chemicals for both users and the environment.

- Consumer Appeal: With a growing demand for eco-conscious products, e-cigarettes using sustainable adhesives may attract environmentally aware consumers.

Challenges and Future Outlook

- Performance Standards:Ensuring that sustainable adhesives meet traditional options’ durability and performance criteria remains a challenge in the industry.

- Cost and Scalability:The cost-effectiveness and scalability of eco-friendly adhesive production need further development to compete with conventional options.

- Regulatory Compliance:Manufacturers must navigate regulatory frameworks to ensure the safety and compliance of new adhesive materials.

How Should Users Assess the Quality of E-Cigarette Adhesives?

Electronic cigarettes have gained popularity due to their perceived safety over traditional smoking. However, the quality of components, including adhesives, remains a critical factor in their safety and performance.

Significance of E-Cigarette Adhesives

- Structural Integrity:Adhesives play a crucial role in holding together various components of an e-cigarette, ensuring its structural stability.

- Safety Concerns:When heated, low-quality adhesives may release harmful chemicals, impacting the vapor produced and potentially posing health risks to users.

- Performance Impact:Adhesives affect the overall performance and longevity of an e-cigarette. Subpar adhesives can lead to device malfunctions or premature wear and tear.

Factors to Assess Quality

- Chemical Composition:High-quality adhesives should be free from toxic substances like formaldehyde, acetaldehyde, and other volatile compounds, especially when heated.

- Heat Resistance:The adhesive should withstand the heat generated during vaping without degrading or releasing harmful fumes.

- Certifications and Standards:Look for adhesives that comply with industry standards and certifications, ensuring they meet safety and quality benchmarks.

- Manufacturer Reputation:Trustworthy brands prioritize using safe adhesives and maintain a reputation for product quality and safety.

Testing and Research

- Independent Reviews:Check for reviews or studies on specific e-cigarette brands to understand if any concerns have been raised regarding adhesive quality.

- Material Analysis:Some users conduct or rely on independent material analysis to determine the chemical composition and safety of adhesives used in e-cigarettes.

User Responsibility

- Read Product Information:Pay attention to the information provided by manufacturers regarding the materials used, including adhesives, in the construction of e-cigarettes.

- Regular Maintenance:Proper maintenance of e-cigarettes can prevent adhesive-related issues by ensuring the device remains in optimal condition.

- Dispose Responsibly:When disposing of e-cigarettes, users should consider proper disposal methods to minimize environmental impact, especially concerning adhesives and other components.

What Research Exists on the Safety of E-Cigarette Adhesives?

The rise of electronic cigarettes has sparked debates regarding their safety, and amidst this discussion, the role of adhesives used in their construction remains a topic of interest. While the focus often centers on the liquid and hardware of e-cigarettes, the adhesive compounds also warrant attention.

Understanding E-Cigarette Adhesives

- Adhesives play a crucial role in assembling the various components of e-cigarettes, such as the battery, cartridge, and heating element.

- These adhesives ensure the device’s structural integrity, preventing leakages and securing the elements.

- Commonly used adhesives include cyanoacrylates, epoxies, and silicones, each with its chemical composition.

Existing Research and Safety Concerns

- Limited studies specifically address the safety of adhesives in e-cigarettes.

- Research has primarily focused on the health implications of e-cigarette liquids and their vapor.

- However, some concerns have been raised about the potential risks associated with the heating and vaporization of adhesive compounds.

The Need for Comprehensive Studies

- Given the lack of extensive research, there’s a critical need for comprehensive studies evaluating the safety of these adhesive compounds.

- These studies should encompass the impact of heat, inhalation, and potential chemical reactions when adhesive compounds are heated.

Potential Health Implications

- Heating adhesives may lead to the release of volatile organic compounds (VOCs) or other harmful substances.

- Inhalation of these compounds could pose risks to respiratory health.

- The long-term effects of inhaling vaporized adhesive components remain largely unknown.

Regulatory Considerations and Industry Responsibility

- Regulatory bodies should consider including adhesive compounds in their assessments and regulations concerning e-cigarette safety.

- Manufacturers are responsible for prioritizing safe adhesive materials and conducting thorough safety evaluations.

Are there Allergies Associated with E-Cigarette Adhesives?

In recent years, electronic cigarettes, or e-cigarettes, have gained significant popularity as an alternative to traditional smoking. However, concerns about the materials used in these devices have emerged, including the adhesive components. While many focus on the liquid and battery aspects, the adhesive holding these devices together warrants attention, raising questions about potential allergies.

Understanding Electronic Cigarette Adhesives

- Adhesives in E-Cigarettes:These devices often comprise various materials, including adhesives, to hold components together. Adhesives play a crucial role in ensuring the stability and functionality of e-cigarettes.

- Adhesive Types:Cyanoacrylate, epoxy, and silicone-based adhesives are commonly used in e-cigarette assembly due to their strength and resistance to temperature changes.

- Potential Allergens:Adhesive components may contain compounds that some individuals could be allergic to, causing adverse reactions upon exposure.

Allergic Reactions and Concerns

- Skin Contact Allergies: Direct skin contact with adhesives can lead to allergic reactions such as redness, itching, or rashes. Users might experience discomfort or irritation at the point of contact.

- Respiratory Allergies:Vapor emitted by e-cigarettes might contain traces of adhesive components. For individuals sensitive to these compounds, inhalation could trigger respiratory issues or exacerbate conditions like asthma.

Mitigating Allergy Risks

- Material Awareness:Manufacturers can enhance transparency by disclosing the types of adhesives used in their products. It allows users to identify potential allergens and make informed decisions.

- Testing and Certification:Rigorous testing and certification processes can help identify and eliminate potentially allergenic compounds in adhesives, ensuring safer products for consumers.

Can Adhesive Impact E-Cigarette Maintenance?

E-cigarettes have become a popular alternative to traditional smoking, offering a cleaner and potentially safer option. However, their maintenance is crucial for optimal performance. Surprisingly, the adhesive used in construction is one often overlooked factor in e-cigarette maintenance. Here’s how electronic cigarette adhesive can significantly impact maintenance:

- Sealing Integrity:Adhesive plays a vital role in sealing the components of an e-cigarette. Any compromise in this seal due to poor adhesive quality can lead to leakages, affecting the device’s functionality and user experience.

- Durability:High-quality adhesive ensures the durability of the device. It prevents parts from loosening or detaching, enhancing the longevity of the e-cigarette. Conversely, low-quality adhesive might result in frequent disintegration, increasing maintenance needs.

- Heat Resistance:E-cigarettes generate heat during operation. The adhesive used must withstand this heat to maintain its adhesive properties. If the adhesive fails under high temperatures, it can cause parts to loosen or detach, affecting the device’s functionality.

- Moisture Protection:Adhesive helps prevent moisture ingress, which is crucial for the protection of internal electronic components. Moisture can corrode the circuitry, leading to malfunctioning and potentially rendering the device unusable.

- Cleaning Challenges:Some adhesives are more prone to collecting dust and debris, making cleaning the device a more cumbersome task. Residue from low-quality adhesive can build up and interfere with the device’s operation, necessitating frequent and thorough cleaning.

- Compatibility with Materials:Different materials are used in e-cigarette construction. The adhesive should be compatible with these materials to ensure a secure bond. Incompatibility can lead to adhesive failure and compromise the structural integrity of the device.

Proper maintenance of e-cigarettes involves more than just cleaning and battery care. Considering the impact of adhesive on device performance is crucial. Users can ensure longevity and functionality by choosing e-cigarettes constructed with high-quality adhesive.

How does Adhesive Impact the Design of E-Cigarettes?

E-cigarettes, known for their sleek design and innovative technology, rely on various components to function effectively. Among these elements, the often underestimated yet critical factor in their design is the adhesive used. Here’s a closer look at how electronic cigarette adhesive impacts their overall design:

- Structural Integrity:Adhesive is the binding force for different components of an e-cigarette. It ensures the structural integrity of the device, holding together various parts such as the battery, tank, and mouthpiece. High-quality adhesive contributes to a sturdy, well-built design.

- Seamless Integration:A well-selected adhesive facilitates the seamless integration of different materials used in the construction of e-cigarettes. Whether joining metal, plastic, or glass components, the adhesive must provide a strong bond without compromising the device’s aesthetics.

- Form Factor and Ergonomics:The choice of adhesive affects the form factor and ergonomics of e-cigarettes. A strong yet flexible adhesive allows for sleek and ergonomic designs, contributing to user comfort and convenience during handling and use.

- Leak Prevention:Adhesive quality directly impacts the prevention of leaks in e-cigarettes. A reliable adhesive creates a tight seal between components, such as the tank and the device body, ensuring no e-liquid leakage. This crucial aspect enhances user experience and minimizes potential mess.

- Heat Resistance and Safety:E-cigarettes generate heat during operation. The adhesive must be heat-resistant to maintain its integrity and prevent any risk of melting or releasing toxic fumes. Ensuring the safety of the adhesive material is paramount for user health and device reliability.

- Innovative Features Implementation:Advanced functionalities, such as temperature control or airflow adjustments, often require intricate design elements. Adhesive compatibility with these features is essential for their successful integration into the overall design of the e-cigarette.

- Manufacturability and Cost:Adhesive selection impacts the manufacturing process and overall cost. Efficient adhesives streamline assembly processes, reducing production time and costs without compromising quality.

What Are the Future Trends in E-Cigarette Adhesive Technology?

In the ever-evolving world of electronic cigarettes (e-cigarettes), the role of adhesive technology is often underestimated. However, it’s a crucial element that contributes significantly to the performance, safety, and overall user experience. As the industry continues to expand, future trends in e-cigarette adhesive technology are poised to revolutionize how these devices are manufactured and used.

Let’s delve into the emerging trends shaping the future landscape of electronic cigarette adhesives:

Advanced Materials

- Nano adhesives:Utilizing nanotechnology to develop adhesives that offer enhanced bonding strength and durability, ensuring components stay securely in place within the e-cigarette.

- Bio-based adhesives: Moving towards eco-friendly solutions derived from natural sources, reducing environmental impact without compromising performance.

Customized Formulations

- Temperature-resistant adhesives:To address the heat generated by e-cigarettes, manufacturers are developing adhesives capable of withstanding higher temperatures without deteriorating.

- Chemical-resistant adhesives: Creating adhesives resistant to the corrosive nature of e-liquids, ensuring stability and longevity of the device’s components.

Application Techniques

- Precision dispensing systems:Implementing advanced dispensing methods to apply adhesives accurately and efficiently during manufacturing, optimizing product quality and consistency.

- Automated assembly lines:Integrating mechanical systems for adhesive application, reducing human error, and enhancing productivity in mass production.

Safety and Compliance

- Adhesives with low volatile organic compounds (VOCs): Striving for formulations that minimize harmful emissions, promoting user safety and meeting regulatory standards.

- Health-conscious formulations:Research into adhesives that release fewer toxins when heated, prioritizing user health and well-being.

Integration of Smart Technologies

- Conductive adhesives: Developing adhesives with electrical conductivity properties, facilitating seamless integration of electronic components, and ensuring efficient functioning.

- Sensor-embedded adhesives: Exploring adhesives embedded with sensors to monitor device usage, temperature variations, and battery performance for enhanced safety and user experience.

Collaborative Research and Innovation

- Industry partnerships:Collaborative efforts between adhesive manufacturers, e-cigarette companies, and research institutions to drive innovation and develop cutting-edge adhesive solutions.

- Continuous R&D investment: Investing in ongoing research and development to stay at the forefront of technological advancements and address evolving consumer demands.

How Should Users Dispose of E-Cigarettes Considering Adhesive Components?

In recent years, electronic cigarettes (e-cigarettes) have gained immense popularity as an alternative to traditional smoking. However, as users enjoy the convenience and potential health benefits, there arises a critical concern: the proper disposal of e-cigarettes, especially considering the presence of electronic cigarette adhesive components. Let’s delve into the importance of responsible disposal and how users should handle e-cigarettes at the end of their lifespan.

The Role of Electronic Cigarette Adhesive

- E-cigarettes are intricate devices comprising various components, including batteries, cartridges, and an array of adhesive materials.

- Adhesives play a crucial role in keeping different parts securely in place, contributing to the device’s overall functionality.

Environmental Impact

- The improper disposal of e-cigarettes can lead to environmental hazards due to the presence of hazardous materials, including adhesives.

- Electronic cigarette adhesive components may contain substances that, if not disposed of responsibly, can potentially leach into the soil and water, posing a risk to ecosystems.

Steps for Responsible Disposal

- Separate Components:Before disposal, disassemble the e-cigarette into its components. It includes removing the battery, cartridge, and any other detachable parts.

- Recycling Batteries:Batteries, a vital component of e-cigarettes, should be recycled separately. Many local recycling programs have specific guidelines for battery disposal.

- Check Local Regulations:Different regions may have specific regulations regarding the disposal of e-cigarettes and their components. Users should familiarize themselves with local guidelines to ensure compliance.

- Dispose of Adhesives Properly:Adhesive components should be handled with care. Check for any recycling options for adhesive materials. If recycling is not available, place them in the general waste bin.

- Secure Disposal Bags:Consider using disposal bags for each component to prevent any potential leakage of harmful substances. It ensures the waste is contained and does not pose a risk during transportation.

- Collection Programs:Some manufacturers or local entities may offer collection programs for e-cigarette components. Users should explore these options to ensure that their e-cigarettes are disposed of in an environmentally friendly manner.

What Should Consumers Look for in E-Cigarette Adhesive Labels or Specifications?

Electronic cigarettes have expanded rapidly, offering consumers a vast array of choices. The adhesive labels or specifications accompanying these products are among the essential elements often overlooked. These labels are crucial in ensuring safety, authenticity, and product information. When considering e-cigarette adhesive labels or specifications, consumers should look for several key aspects:

Legitimate Brand Information

- Authentic adhesive labels should prominently feature the manufacturer or distributor’s brand name, logo, and contact information.

- Look for consistency in branding across packaging and labels to identify genuine products.

Clear Product Details

- Labels should provide clear information about the contents, including nicotine levels, flavor additives, and other pertinent ingredients.

- Check for clarity in usage instructions and warnings to ensure safe and appropriate usage.

Compliance with Regulations

- Ensure the label meets the regulatory standards of the region or country. Compliance might include warnings about nicotine content, age restrictions, and health advisories.

- Look for certifications or compliance marks indicating adherence to safety and quality standards.

Durability and Quality of Adhesive

- The adhesive used on labels should be durable and moisture-resistant, ensuring it remains intact throughout the product’s lifespan.

- Labels should not easily peel off, ensuring continued access to essential information.

Authenticity Features

- Some labels might feature anti-counterfeit measures, such as holographic stickers or unique identifiers, to verify the product’s authenticity.

- Consumers should be wary of missing or tampered-with labels, which could indicate potential counterfeit goods.

Clarity in Batch and Expiry Information

- Labels should display batch numbers, manufacturing, and expiration dates for traceability and safety purposes.

- Verify the freshness and validity of the product by checking this information before purchase.

Eco-friendly and Safe Material Usage

- Labels should ideally use eco-friendly materials that are safe for the environment and do not pose risks upon disposal.

- Consumers concerned about sustainability can look for labels made from recyclable materials.

CONCLUSION

The landscape of electronic cigarettes is a tapestry woven with components often overshadowed by their more conspicuous counterparts. However, the unassuming Electronic Cigarette Adhesive emerges as a linchpin for safety, performance, and user satisfaction. As consumers navigate the plethora of options, Awareness of adhesive significance empowers informed decisions. By recognizing its influence on device integrity, longevity, and even environmental impact, users wield a critical tool in their hands, an instrument that shapes not just their vaping experience but potentially their safety. Awareness paves the way for a safer, more discerning vaping landscape.

DeepMaterial

Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. More…

UV Curing Adhesives

UV light cure have a number of benefits making them a popular choice among many product assembly and manufacturing applications. Many UV light cure adhesives can provide a nearly instantaneous bond to difficult substrates like glass and plastic. UV cure adhesives often require an accelerator or UV light for a bond to form.

Adhesive Blogs & News

The latest adhesive industry science and technology, Deepmaterial news, and market trends and forecasts.

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy

The Quantitative Influence of Crosslinking Density on the Flexibility and Hardness of Adhesives and the Formulation Optimization Strategy This article systematically expounds the quantitative relationship between the crosslinking density and the flexibility and hardness of adhesives. Combining the theories of polymer physics with experimental analysis methods, it reveals the mechanism of the action of the

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives

Technical Strategies for Balancing the Rapid Curing Property and Long Operating Time of UV Adhesives UV adhesives have been widely used in many fields such as electronics, optics, and medicine due to their advantages of rapid curing, high bonding strength, and environmental protection. However, their rapid curing property also brings challenges in some application scenarios.

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields

Biocompatibility of LED UV Glue Adhesive and Its Application Potential in Medical and Food Packaging Fields LED UV glue adhesive has been widely applied in numerous fields due to its advantages such as rapid curing and easy operation. However, in fields with stringent safety requirements like medical and food packaging, its biocompatibility after curing

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions

Influence of Viscosity and Thixotropy of Glue on the Quality of Glue Dots in the Dispensing Process and Solutions The dispensing process is an important part of the application of LED UV glue adhesive, and the quality of this process directly affects the final performance of the product. The physical properties of the glue,