- Home

- >

- Material Bonding

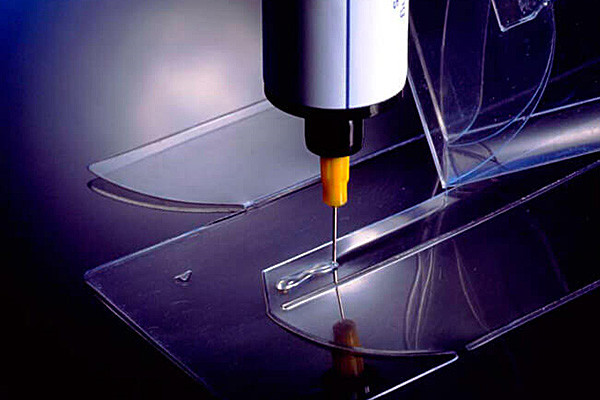

A variety of adhesives readily material bonding. It can be challenging to choose the best metal bonding adhesive, since there are so many options available. Each chemistry has its own unique benefits.

In contrast, adhesives can provide multiple benefits as an alternative to the traditional methods. For example, liquid adhesives can flow and conform to the shape of the bond area to fill gaps. They typically provide strong bonds. It comes in multiple formats providing design and production flexibility. In addition to formats, adhesives come in a variety of strengths to match a wide range of substrate and design needs.

Industrial adhesives provide key benefits over other industrial assembly methods, including:

*Eliminate drilling and holes to reduce labor costs and stress concentration

*Use thinner, lightweight materials to reduce product weight and energy usage

*Distribute stress evenly across the bond to optimize performance

*Bond dissimilar materials to enable new designs and prevent corrosion

*Bond and seal simultaneously to eliminate process steps

*Reduce vibration in final product to enhance customer experience