Low Yellowing & Fast Curing UV Liquid OCA Glue for Touch Screens

The relentless pursuit of thinner, brighter, and more durable display technologies has placed immense pressure on the materials used in their assembly. Optical Clear Adhesives (OCAs) are critical components in modern touch screen modules, responsible for laminating the cover glass to the sensor and display unit. While traditional film OCAs have served the industry well, the emergence of advanced display architectures—such as flexible OLEDs, under-display cameras, and ultra-narrow bezels—has exposed their limitations. This article explores the technological leap offered by a new class of UV-curable liquid Optical Clear Adhesives (LOCAs) engineered specifically for low yellowing and ultra-fast curing. We delve into the chemical principles behind their superior optical clarity, the manufacturing efficiencies gained through rapid photopolymerization, and their pivotal role in enabling the next generation of electronic devices.

The Critical Role of Optical Bonding

In a touch screen module, the air gap between the cover glass (lens) and the display (LCD or OLED) is a significant source of optical inefficiency. This air gap causes light to refract and reflect at each interface, reducing contrast and brightness. Optical bonding is the process of filling this gap with a transparent adhesive, effectively marrying the layers into a single optical unit. This process yields several critical benefits:

-

Enhanced Optical Performance: By eliminating the air gap, refractive index matching reduces surface reflections, significantly improving sunlight readability, contrast ratio, and perceived color vibrancy.

-

Increased Durability: The adhesive layer acts as a shock absorber, improving the drop and impact resistance of the display module.

-

Dust-Proof and Moisture Barrier: Bonding seals the display, preventing the ingress of dust and moisture, which can cause corrosion and failure.

For years, the industry standard has been film OCA, supplied as pre-cut sheets of solid, pressure-sensitive adhesive. However, as display technology evolves, the limitations of film OCA are becoming increasingly apparent, paving the way for liquid OCA (LOCA).

The Shift from Film OCA to Liquid OCA

Film OCA is applied under pressure (lamination) and often requires an autoclave process to remove bubbles and ensure complete wet-out. While effective, this method presents several challenges:

-

Limited Gap Filling: Film OCA has a fixed thickness and cannot conform well to step differences caused by printed borders, bezels, or underlying circuitry. This leads to poor edge coverage and bubble entrapment.

-

Handling and Yield Issues: Die-cutting and handling thin, tacky films can be problematic. Dust or contamination during lamination is a major cause of yield loss.

-

Incompatibility with Curved Surfaces: Film OCA struggles to conform to the complex 3D curvatures found in many modern “waterfall” displays without wrinkling or deforming.

Liquid OCA is applied as a viscous fluid, dispensed directly onto the substrate. This fluid nature offers transformative advantages:

-

Superior Conformability: It flows to fill every microscopic crevice, perfectly wetting out the surface and seamlessly covering step differences and curved contours.

-

Bubble-Free Bonding: The liquid application process inherently eliminates the risk of air entrapment, a common failure mode in film lamination.

-

Thinner Bond Lines: It enables extremely thin and uniform bond lines, crucial for overall module thinness and optical clarity.

The Chemistry of Performance: Understanding Low Yellowing

The primary function of an OCA is to be optically invisible. Any discoloration, particularly yellowing, is unacceptable as it distorts the color gamut of the display and reduces overall brightness. Yellowing is a form of degradation caused by the formation of chromophores (color-bearing chemical groups) within the polymer matrix. The main culprits are:

-

Photo-oxidation: Prolonged exposure to high-energy blue light and UV radiation from the display backlight can break chemical bonds, leading to the formation of colored species.

-

Thermal Aging: Heat generated by the device’s processor and display can accelerate oxidation reactions.

-

Impurities and Catalysts: Residues from polymerization initiators or other additives can degrade over time, causing yellowing.

Achieving “low yellowing” requires a sophisticated approach to polymer chemistry, specifically using UV cationic curing mechanisms.

Traditional free-radical UV curing, while fast, is susceptible to oxygen inhibition. This results in incomplete curing at the surface and can leave behind reactive species that degrade over time. Furthermore, the acrylate-based polymers used in free-radical systems are inherently more prone to oxidation and yellowing.

In contrast, advanced low-yellowing UV liquid OCAs utilize a cationic curing mechanism.

-

Photoinitiator Activation: Upon exposure to UV light, a cationic photoinitiator (typically a diaryliodonium or triarylsulfonium salt) decomposes to form a strong Brønsted acid.

-

Ring-Opening Polymerization: This acid protonates the epoxy or oxetane functional groups in the resin, initiating a ring-opening polymerization. This process creates a polymer network with polyether linkages.

The benefits of this chemistry for low yellowing are profound:

-

No Oxygen Inhibition: Cationic polymerization is not inhibited by oxygen, ensuring complete and uniform curing even at the surface.

-

“Living” Polymerization: The acid catalysts are not consumed in the reaction. They can remain active, allowing for continued curing even after the UV light source is removed (“dark cure”). This leads to a more complete and stable polymer network with fewer unreacted, unstable components.

-

Inherent Stability: The resulting polyether-based polymer backbone is significantly more resistant to oxidation and UV degradation than the acrylate-based polymers from free-radical systems. This inherent chemical stability is the cornerstone of long-term optical clarity and low yellowing, ensuring the adhesive remains water-white for the lifespan of the device, even under demanding conditions.

The Need for Speed: Fast Curing in High-Volume Manufacturing

In the competitive consumer electronics market, manufacturing throughput is directly tied to profitability. “Fast curing” is not just a convenience; it is an economic imperative. The curing speed of a UV LOCA dictates the cycle time of the lamination process and the required footprint of curing equipment.

Fast curing is achieved by optimizing several factors:

-

High Photoinitiator Efficiency: The cationic photoinitiators are designed for high quantum yield, meaning they generate a large number of acid molecules per photon of light absorbed.

-

Reactive Resin Formulation: The epoxy or oxetane resins are chosen for their high reactivity with the photogenerated acid, leading to rapid chain propagation.

-

Matched UV Spectrum: The photoinitiator is tuned to absorb strongly at the specific emission wavelengths of common UV LED lamps (e.g., 365 nm or 395 nm). This ensures maximum energy utilization.

A UV liquid OCA engineered for fast curing can be fully tack-free and achieve its final handling strength in seconds, or even milliseconds, under a high-intensity UV LED lamp. This eliminates the need for lengthy batch processing in an autoclave, enabling:

-

In-Line Processing: The bonding step can be integrated directly into the assembly line, with the device moving from the dispense station, through alignment, and immediately under a UV lamp for curing.

-

Reduced Floor Space: Eliminating large autoclave ovens saves valuable cleanroom space.

-

Lower Energy Consumption: UV LED curing is far more energy-efficient than thermal processes.

-

Just-in-Time Manufacturing: The instantaneous nature of the cure allows for greater flexibility in production scheduling.

Application Methods and Process Integration

The adoption of UV liquid OCA glue requires a shift in manufacturing process, but one that is well-established in the industry. The two primary methods for dispensing are:

-

Slit Dispensing: A narrow slit valve dispenses a precise, uniform bead of glue across the width of the panel as it moves underneath. This method is excellent for high-speed, high-volume production of flat panels.

-

Dispense-and-Spread (Dam-and-Fill): A controlled amount of LOCA is dispensed in a pattern (e.g., a star or dot pattern) onto the center of the substrate. The top substrate is then lowered at a controlled speed, compressing the liquid and forcing it to flow outward to the edges, filling the entire gap. This method is versatile for different sizes and shapes, including curved surfaces.

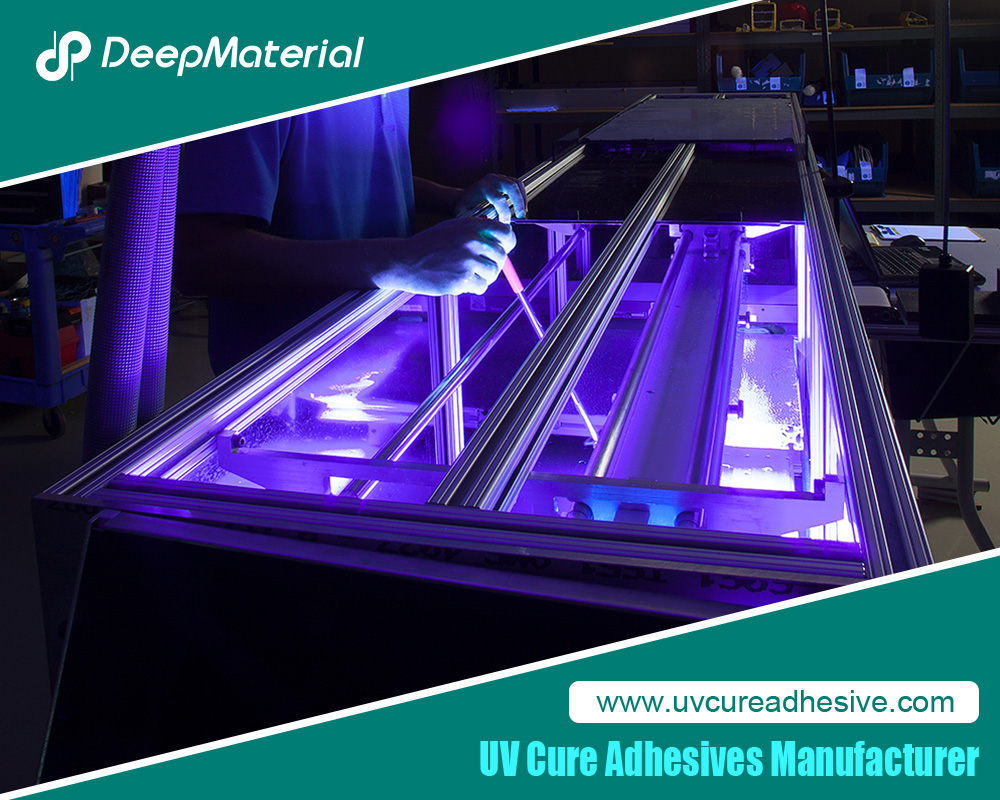

After dispensing and mating the substrates, a precise alignment is performed. The final step is exposure to high-intensity UV light. For fast-curing formulations, this is typically done using an array of high-power UV LEDs, which provide a cool, intense, and uniform light source without the heat and mercury waste of arc lamps. The result is a fully bonded module, ready for the next stage of assembly in seconds.

Addressing Specific Touch Screen Challenges

Modern low-yellowing, fast-curing UV liquid OCAs are designed to solve the most pressing challenges in touch screen manufacturing:

-

Edge Coverage and Bezel Step Coverage: The low viscosity and high wettability allow the LOCA to flow up and over the opaque ink step of the bezel, creating a seamless bond right to the edge of the glass. This prevents air gaps that cause light leakage and improves the aesthetic “infinite screen” look.

-

Flexible Displays: For foldable and rollable devices, the adhesive must be not only clear and fast-curing but also flexible. Advanced formulations incorporate soft segments into the polymer network to provide the necessary elongation and elasticity to survive millions of folding cycles without cracking or delaminating.

-

Under-Display Cameras (UDC): The adhesive layer sits directly in the path of the camera sensor. It must exhibit near-perfect transmittance across the entire visible spectrum and have minimal haze to avoid scattering light and degrading image quality. The low-yellowing property is absolutely critical here to prevent color shifting in captured photos.

-

Outdoor and Automotive Displays: In automotive and outdoor applications, displays are subjected to extreme temperatures and intense direct sunlight. The thermal and UV stability of the cationic polymer matrix ensures the bond remains strong and optically clear for years, resisting delamination and yellowing caused by solar radiation.

Future Trends and Conclusion

The trajectory of display technology is clear: towards higher resolution, greater brightness, more complex shapes, and increased integration of sensors. UV liquid OCA technology is evolving in parallel.

We can expect future formulations to offer even faster curing speeds, perhaps triggered by visible light to further reduce any risk to sensitive components. The development of hybrid materials, incorporating nanoparticles for enhanced refractive index matching or thermal conductivity, is also on the horizon. Furthermore, materials designed for easy disassembly (“debonding on demand”) will become increasingly important for device repair and recycling, supporting a circular economy.

In conclusion, the combination of low yellowing and fast curing in UV liquid OCA glue represents a significant advancement in materials science for electronics manufacturing. By leveraging the stability of cationic, ring-opening polymerization and the efficiency of modern UV LED technology, these adhesives solve the critical limitations of traditional film OCAs. They are not just a product improvement; they are an enabling technology that allows manufacturers to meet the stringent demands of next-generation touch screens, from the perfectly flat smartphone to the futuristic foldable tablet and the durable automotive display, all while ensuring pristine optical quality and maximizing production efficiency.

For more about low yellowing & fast curing UV liquid OCA glue for touch screens, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.