Compatibility Analysis and Countermeasures of LED UV Glue with Automated Production Equipment

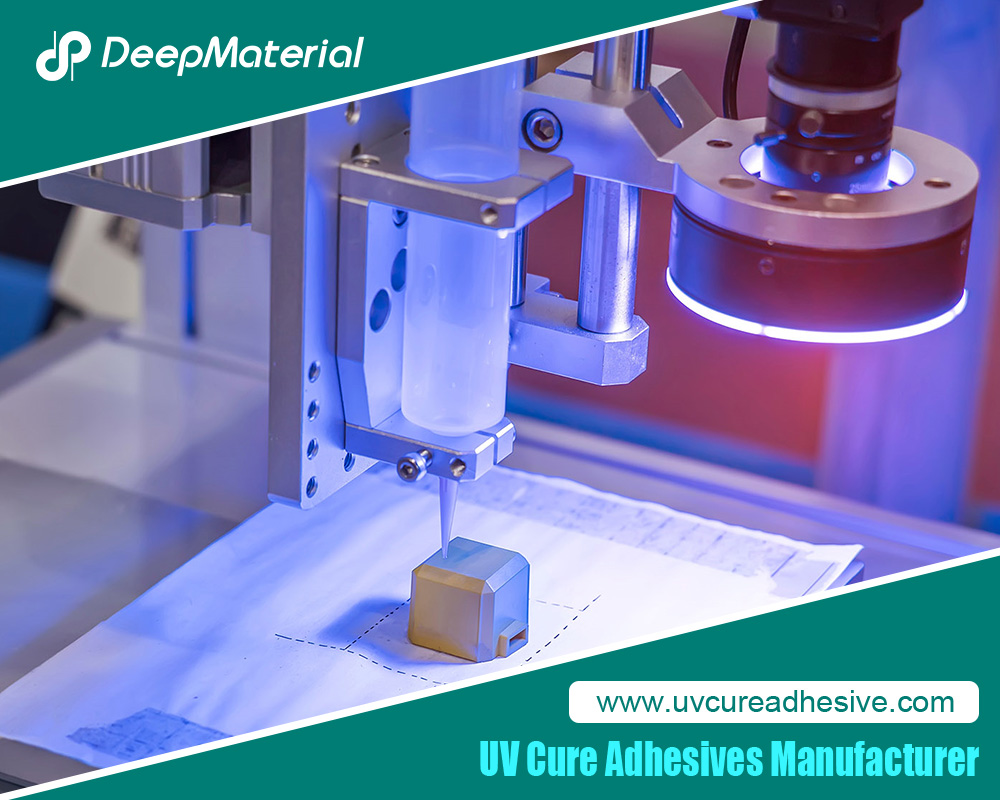

LED UV glue has been widely used in modern manufacturing due to its advantages such as fast curing speed, high bonding strength, and environmental friendliness. However, in the automated production process, if there are problems with the adaptability between the glue and equipment like dispensing machines and curing ovens, it will lead to production interruptions and an increase in the defective product rate. Understanding the compatibility issues between the glue and the equipment is of great significance for improving production stability and product quality.

Compatibility Issues and Analysis between LED UV Glue and Dispensing Machines

1. Nozzle Clogging Problems

1) Reasons for Clogging

- Viscosity Change of the Glue: During the storage or use of LED UV glue, if there are fluctuations in the ambient temperature, its viscosity will change. When the viscosity of the glue increases, its fluidity deteriorates, and it is likely to accumulate at the nozzle, causing clogging. For example, in a relatively low-temperature environment, some glues containing high polymers will experience a significant increase in viscosity.

- Pre-curing Phenomenon: UV glue is sensitive to ultraviolet light. Even trace amounts of ultraviolet light in the environment, such as the ultraviolet component in workshop lighting, may trigger slight pre-curing. The pre-cured glue gradually accumulates inside the nozzle, eventually leading to clogging.

- Impurity Mixing: If the packaging of the glue is not tightly sealed during storage or transfer, dust, impurities, and other particulate matters may mix in. These substances will form a blockage at the nozzle.

2) Impact Analysis

Nozzle clogging will lead to inaccurate dispensing volume, resulting in insufficient glue or glue breakage, affecting the bonding effect and appearance quality of the product. Frequent nozzle clogging will also increase the downtime for equipment maintenance, reduce production efficiency, and increase production costs.

2. Equipment Corrosion Problems

1) Reasons for Corrosion

- Effect of Chemical Components: Some components of LED UV glue, such as certain monomers, initiators, and additives, may have chemical activity and can react chemically with the materials of dispensing machine nozzles, pipelines, and other components (such as metals, rubbers, plastics, etc.). For example, some glue components with strong acidity or alkalinity may corrode metal nozzles.

- Solvent Erosion: To adjust the viscosity and fluidity of the glue, some organic solvents are added to part of the UV glue. These organic solvents may cause swelling and deformation of the sealing parts, pipelines, and other components of the equipment after long-term contact, reducing the sealing performance and service life of the components.

2) Impact Analysis

After the equipment components are corroded, the sealing performance will decrease, and glue leakage will occur, affecting the dispensing accuracy and the production environment. In severe cases, corrosion will damage key components such as nozzles and pipelines, requiring frequent replacement, which increases the equipment maintenance cost and downtime.

Compatibility Issues and Analysis between LED UV Glue and Curing Ovens

1. Temperature Adaptability Problems

- Reasons for the Problem

During operation, the curing oven will generate a certain temperature. Although LED UV glue mainly cures by ultraviolet light, an excessively high ambient temperature may affect the performance and curing effect of the glue. On the one hand, high temperature may accelerate the pre-curing of the glue, causing the glue to be partially cured before entering the curing oven, affecting the final curing quality. On the other hand, different types of LED UV glue have different temperature tolerances. If the temperature setting of the curing oven is inappropriate, it may change the performance of the glue, such as generating bubbles and internal stress.

- Impact Analysis

An inappropriate temperature will lead to incomplete curing of the glue and a decrease in its post-curing performance, such as reduced bonding strength and insufficient hardness, affecting the quality and reliability of the product. At the same time, excessively high temperatures may also damage the bonded materials, such as causing deformation and discoloration of plastic substrates.

2. Uneven Ultraviolet Irradiation Problems

- Reasons for the Problem

Factors such as the distribution of ultraviolet light sources in the curing oven, the design of the reflector plate, and the ventilation structure will all affect the uniformity of ultraviolet irradiation. If the light source is aging, the surface of the reflector plate is uneven, or there are stains, it will lead to insufficient ultraviolet intensity in some areas, resulting in insufficient curing of the glue. In some areas, excessive ultraviolet intensity may cause over-curing of the glue and generate internal stress.

- Impact Analysis

Uneven ultraviolet irradiation will make the curing quality of the glue inconsistent, resulting in unstable product performance. For example, in the bonding of optical devices, uneven curing will affect the optical performance of the product, resulting in inconsistent light transmittance, optical distortion, and other problems.

Strategies for Improving the Compatibility of LED UV Glue with Automated Equipment

1. Optimization Strategies for Dispensing Machines

1) Optimization of Glue Management

- Temperature Control: Strictly control the ambient temperature during the storage and use of the glue. A constant-temperature storage cabinet can be used to store the glue to ensure that the glue is within an appropriate viscosity range. During the dispensing process, the temperature of the glue storage container of the dispensing machine can also be controlled to avoid fluctuations in the glue viscosity due to temperature changes.

- Measures against Pre-curing: Use light-proof containers to store the glue to reduce the influence of ultraviolet light on the glue. In the production workshop, lighting equipment without ultraviolet light can be used to prevent the ultraviolet light in the environment from triggering the pre-curing of the glue. At the same time, during the transfer and dispensing of the glue, try to reduce the time the glue is exposed to the air.

- Filtration Treatment: Before the glue enters the dispensing machine, filter the glue to remove any possible impurities. An appropriate precision filter can be selected, such as a filter element with a precision of 0.2 – 0.5 microns, to ensure the purity of the glue.

2)Selection and Maintenance of Equipment Materials

- Material Adaptation: Select equipment materials that are compatible with the glue according to its chemical composition. For example, for corrosive glues, corrosion-resistant materials such as stainless steel and polytetrafluoroethylene can be used to make nozzles and pipelines. For glues with a high content of organic solvents, fluororubber and other materials with good swelling resistance can be used for the sealing parts.

- Regular Maintenance: Formulate a strict equipment maintenance plan, and regularly clean and inspect nozzles, pipelines, and other components. When cleaning, special cleaning agents can be used to remove residual glue and impurities. At the same time, check the corrosion situation of the components and replace the damaged components in a timely manner.

2. Optimization Strategies for Curing Ovens

1) Temperature and Ultraviolet Control

- Temperature Adjustment: Before using a new type of LED UV glue, conduct a temperature adaptability test to determine the optimal temperature range for the glue to cure. According to the test results, reasonably set the temperature of the curing oven, and install a temperature sensor to monitor the temperature inside the oven in real-time to ensure that the temperature is stably within the appropriate range.

- Ultraviolet Optimization: Regularly check and replace the ultraviolet light sources in the curing oven to ensure that the intensity and wavelength of the light sources meet the requirements for glue curing. Optimize the design and cleaning maintenance of the reflector plate to improve the reflection efficiency and irradiation uniformity of ultraviolet light. Optical simulation software can be used to simulate and analyze the ultraviolet light distribution inside the curing oven to guide the design and adjustment of the reflector plate.

2) Optimization of Process Parameters

- Adjustment of Curing Time: Optimize the curing time parameters according to the characteristics of the glue and the performance of the curing oven. Determine the optimal curing time for different glues in this curing oven through experiments to avoid quality problems caused by too long or too short curing time.

- Product Placement and Conveyance: Reasonably design the placement method and conveying speed of the products inside the curing oven to ensure that the products can receive uniform ultraviolet irradiation. For example, for products with irregular shapes, special fixtures or brackets can be used for fixing and placement to ensure that every part can be fully cured.

Conclusion

The compatibility issues between LED UV glue and automated production equipment involve multiple aspects and require comprehensive consideration and optimization from multiple perspectives such as glue characteristics, equipment materials, and process parameters. Through reasonable glue management, equipment material selection, process parameter adjustment, and strict equipment maintenance, problems such as nozzle clogging and equipment corrosion can be effectively solved, the compatibility between the glue and the equipment can be improved, the efficient and stable operation of automated production can be ensured, and the product quality and the economic benefits of the enterprise can be enhanced. In the future, with the continuous development of LED UV glue and automated production equipment technologies, it is still necessary to continuously pay attention to the compatibility issues between the two and explore better solutions.

For more about compatibility analysis and countermeasures of LED UV glue with automated production equipment, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.