UV Cure Acrylic Adhesive Manufacturer: Driving Innovation in Bonding Technology

In the dynamic world of industrial manufacturing, adhesives are critical for creating durable, high-performance products. Among these, UV-cure acrylic adhesives have gained prominence for their rapid curing, strong bonding, and versatility across industries. UV cure acrylic adhesive manufacturers play a pivotal role in developing and supplying these advanced materials, enabling applications in electronics, automotive, medical devices, and more. These manufacturers combine materials science expertise with cutting-edge production techniques to deliver adhesives that meet stringent performance and sustainability requirements.UV-cure acrylic adhesives, which solidify under ultraviolet (UV) light, offer unmatched speed, precision, and environmental benefits compared to traditional adhesives. Manufacturers are at the forefront of formulating these adhesives to suit diverse substrates and applications, from optical bonding in smartphones to structural bonding in aerospace. This article explores the role of UV-cure acrylic adhesive manufacturers, the properties and applications of their products, production processes, industry challenges, and emerging trends. As demand for efficient, eco-friendly, and high-performance bonding solutions grows, these manufacturers are shaping the future of adhesive technology, driving innovation across global industries.

The Role of UV Cure Acrylic Adhesive Manufacturers

UV-cure acrylic adhesive manufacturers are specialized companies that design, produce, and distribute adhesives that cure rapidly under UV light. These manufacturers combine expertise in polymer chemistry, engineering, and manufacturing to create adhesives tailored to specific industry needs. Their role extends beyond production to include research and development (R&D), quality assurance, and technical support for customers.Manufacturers formulate UV-cure acrylic adhesives using acrylic monomers, oligomers, photoinitiators, and additives. The photoinitiators are key, absorbing UV light (typically 320–400 nm) to initiate a photochemical reaction that transforms the liquid adhesive into a solid polymer in seconds. This rapid curing process is ideal for high-throughput industries like electronics and automotive manufacturing.Leading manufacturers, such as Henkel, 3M, and Dymax, invest heavily in R&D to develop adhesives with enhanced properties, such as optical clarity, flexibility, or chemical resistance. They also provide customized formulations to meet specific application requirements, such as bonding glass in displays or securing medical devices. Additionally, manufacturers offer technical support, including guidance on adhesive selection, application techniques, and curing equipment integration.By collaborating with industries like consumer electronics, automotive, and medical, manufacturers ensure their adhesives meet rigorous standards for performance, safety, and sustainability. Their ability to innovate and adapt to evolving market demands positions them as critical partners in modern manufacturing.

Properties of UV-Cure Acrylic Adhesives

UV-cure acrylic adhesives, produced by specialized manufacturers, are prized for their unique properties, which make them suitable for a wide range of applications. Below are their key characteristics:

- Rapid Curing: These adhesives cure in seconds (typically 1–10 seconds) under UV light, enabling fast production cycles and high throughput in manufacturing.

- Strong Adhesion: UV-cure acrylic adhesives bond effectively to diverse substrates, including glass, metal, plastic, and ceramics, providing robust mechanical strength and resistance to delamination.

- Optical Clarity (in specific formulations): Many UV-cure acrylic adhesives are designed for optical applications, offering near-perfect transparency and a refractive index close to glass (approximately 1.5), ideal for display bonding.

- Low Shrinkage: With shrinkage rates below 2% during curing, these adhesives minimize stress on bonded components, ensuring dimensional stability and preventing warping.

- Durability: Once cured, they resist moisture, heat, UV degradation, and chemicals, making them suitable for harsh environments like automotive or outdoor applications.

- Flexibility and Versatility: Manufacturers offer formulations tailored for specific needs, such as flexibility for curved surfaces, high strength for structural bonding, or biocompatibility for medical applications.

- Low Viscosity: The fluid nature of these adhesives allows them to fill micro-gaps and conform to irregular surfaces, eliminating air bubbles and ensuring uniform bonding.

- Environmental Safety: Many UV-cure acrylic adhesives are low-VOC or solvent-free, aligning with eco-friendly manufacturing standards. Additionally, UV curing systems (especially LED-based) reduce energy consumption compared to traditional methods.

These properties make UV-cure acrylic adhesives a preferred choice for industries requiring precision, speed, and reliability. Manufacturers play a critical role in optimizing these properties to meet specific application demands, ensuring consistent performance across diverse use cases.

Applications of UV-Cure Acrylic Adhesives

UV-cure acrylic adhesives, supplied by specialized manufacturers, are used across a wide range of industries due to their versatility and performance. Below are their primary applications:

- Consumer Electronics:

- Manufacturers supply UV-cure acrylic adhesives for bonding components in smartphones, tablets, and laptops. These adhesives are used to secure cover glass to display panels (e.g., LCD or OLED), enhancing optical clarity, touch sensitivity, and durability.

- They are also used in wearable devices like smartwatches, where their flexibility supports curved designs.

- Automotive Industry:

- UV-cure acrylic adhesives are critical in automotive displays, such as infotainment screens and digital dashboards. Their optical clarity ensures readability in bright sunlight, while their durability withstands temperature fluctuations and vibrations.

- Manufacturers provide adhesives for bonding sensors, lighting components, and interior trim, improving vehicle aesthetics and functionality.

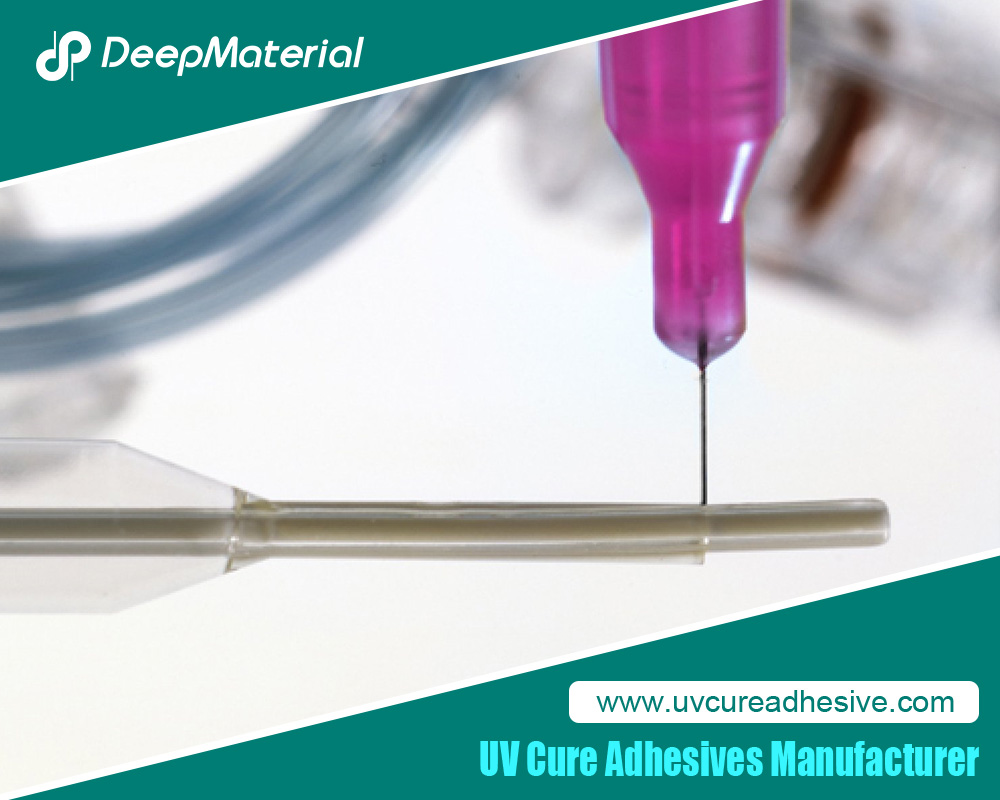

- Medical Devices:

- In medical manufacturing, UV-cure acrylic adhesives are used to assemble devices like catheters, syringes, and diagnostic equipment. Biocompatible formulations ensure safety for medical applications, while their clarity is ideal for optical components in imaging systems.

- Their resistance to sterilization processes makes them suitable for reusable medical devices.

- Optical Bonding:

- Manufacturers produce UV-cure acrylic adhesives for optical bonding in touchscreens, augmented reality (AR) devices, and virtual reality (VR) headsets. These adhesives reduce reflections and improve display performance by filling air gaps between layers.

- Industrial Applications:

- UV-cure acrylic adhesives are used in industrial settings for bonding glass, metal, or plastic components in machinery, control panels, or signage. Their resistance to environmental factors ensures reliability in harsh conditions.

- Aerospace and Defense:

- Manufacturers supply adhesives for bonding components in aerospace displays, sensors, and optical systems. Their high strength and durability are critical for applications exposed to extreme conditions, such as vibrations or temperature variations.

- Consumer Products:

- From home appliances with touch panels to optical instruments like cameras and microscopes, UV-cure acrylic adhesives enable precise, durable bonding in compact designs.

Manufacturers tailor adhesive formulations to meet the specific needs of these applications, ensuring optimal performance and compliance with industry standards.

The Manufacturing Process

The production of UV-cure acrylic adhesives is a complex process that requires precision, expertise, and advanced technology. Manufacturers follow a series of steps to ensure consistent quality and performance:

- Formulation Development:

- Chemists combine acrylic monomers, oligomers, photoinitiators, and additives to create adhesives with desired properties (e.g., clarity, flexibility, or strength). R&D teams test formulations to optimize curing speed, adhesion, and environmental resistance.

- Raw Material Sourcing:

- Manufacturers source high-purity raw materials to ensure adhesive performance and consistency. Photoinitiators, for example, must be carefully selected to match the UV wavelength used in curing.

- Mixing and Blending:

- Raw materials are blended in controlled environments to prevent contamination. Mixing is done under vacuum or inert gas to remove air bubbles and ensure uniformity.

- Quality Testing:

- Manufacturers conduct rigorous tests, including viscosity checks, curing speed analysis, and adhesion strength evaluations, to ensure the adhesive meets industry standards. Optical clarity and refractive index are tested for display applications.

- Packaging:

- The adhesive is packaged in UV-blocking containers (e.g., dark syringes or bottles) to prevent premature curing. Packaging is designed for easy dispensing in automated or manual application systems.

- Technical Support and Customization:

- Manufacturers provide customers with technical data sheets, application guidelines, and curing equipment recommendations. They may also offer customized formulations to meet specific requirements, such as biocompatibility or high-temperature resistance.

- Integration with Curing Systems:

- Manufacturers often collaborate with equipment suppliers to ensure compatibility with UV curing systems, including traditional mercury-vapor lamps or energy-efficient LED UV systems.

The manufacturing process is supported by strict quality control measures and compliance with regulations like ISO standards or REACH for environmental safety. Leading manufacturers invest in automation and digital monitoring to enhance production efficiency and consistency.

Advantages of UV-Cure Acrylic Adhesives

UV-cure acrylic adhesives, produced by specialized manufacturers, offer numerous advantages:

- Rapid Curing: Curing in seconds under UV light streamlines production, reducing costs and increasing throughput.

- Versatile Bonding: These adhesives bond a wide range of substrates, from glass to plastics, making them suitable for diverse applications.

- High Performance: They provide strong, durable bonds resistant to moisture, heat, and chemicals, ensuring long-term reliability.

- Optical Clarity: Formulations for optical bonding enhance display quality by reducing reflections and improving brightness and contrast.

- Eco-Friendly Options: Many adhesives are low-VOC or solvent-free, and LED UV curing systems reduce energy consumption, aligning with sustainability goals.

- Precision Application: Low viscosity ensures uniform bonding and gap-filling, critical for complex assemblies.

- Customizability: Manufacturers offer tailored formulations to meet specific industry needs, such as flexibility or biocompatibility.

These advantages make UV-cure acrylic adhesives a preferred choice for high-performance bonding, supported by manufacturers’ expertise in formulation and application.

Challenges Faced by Manufacturers

UV-cure acrylic adhesive manufacturers face several challenges:

- High R&D Costs: Developing new formulations to meet evolving industry demands requires significant investment in research, testing, and equipment.

- Substrate Compatibility: Ensuring adhesion to diverse or challenging substrates (e.g., low-energy plastics) often requires surface treatments or custom formulations, increasing complexity.

- Curing Equipment Dependency: The adhesives require precise UV curing systems, which can be costly for customers, particularly small-scale manufacturers.

- Environmental Regulations: Compliance with strict regulations (e.g., REACH, RoHS) requires ongoing adjustments to formulations and processes, adding costs.

- Application Precision: Liquid adhesives demand accurate dispensing to avoid defects like bubbles or overflow, necessitating advanced equipment and skilled operators.

- Competition and Cost Pressure: Manufacturers face competition from low-cost alternatives and pressure to reduce prices, particularly for budget-conscious markets.

To address these challenges, manufacturers invest in automation, sustainable practices, and customer education to optimize adhesive performance and reduce costs.

Future Trends and Innovations

The future of UV-cure acrylic adhesive manufacturing is shaped by technological and market trends:

- Sustainable Formulations: Manufacturers are developing bio-based and low-VOC adhesives to meet environmental regulations and customer demand for green solutions.

- LED UV Curing: The shift to energy-efficient LED UV curing systems is driving manufacturers to formulate adhesives optimized for narrow wavelength ranges (e.g., 365–405 nm).

- Flexible and Foldable Applications: As foldable displays and wearables gain popularity, manufacturers are creating adhesives with enhanced flexibility and adhesion to dynamic substrates.

- Smart Adhesives: Innovations include adhesives with self-healing properties or embedded sensors to monitor bond integrity, particularly for aerospace and medical applications.

- Cost Optimization: Advances in production and raw material sourcing aim to reduce costs, making UV-cure acrylic adhesives more accessible to smaller manufacturers.

These trends position manufacturers to meet the evolving needs of industries, driving innovation in bonding technology.

Conclusion

UV-cure acrylic adhesive manufacturers are at the heart of modern bonding technology, supplying high-performance adhesives that enable advanced applications in electronics, automotive, medical, and more. Their expertise in formulation, production, and technical support ensures that UV-cure acrylic adhesives meet the demands of precision, durability, and sustainability. By offering rapid curing, strong adhesion, and optical clarity, these adhesives are critical for creating sleek, reliable, and visually appealing products.Despite challenges like high R&D costs and application complexity, manufacturers are addressing these through innovation, sustainable practices, and customized solutions. Emerging trends, such as eco-friendly formulations and LED UV curing, highlight their commitment to meeting future demands. As industries continue to push for faster, greener, and more reliable bonding solutions, UV-cure acrylic adhesive manufacturers will remain key players, driving advancements in materials science and manufacturing.For businesses and engineers, partnering with reputable manufacturers ensures access to cutting-edge adhesives tailored to specific needs. Their role in enabling next-generation technologies underscores the importance of UV-cure acrylic adhesives in shaping a connected, high-performance world.

For more about UV cure acrylic adhesive manufacturer: driving innovation in bonding technology, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.