A Complete Guide to UV Cure Anaerobic Adhesive: From Formulation Logic to Industrial Applications

In the ever-evolving landscape of industrial bonding solutions, UV cure anaerobic adhesives represent a remarkable fusion of two established curing technologies: ultraviolet (UV) light initiation and anaerobic curing. These adhesives have gained prominence for their versatility, enabling rapid assembly in manufacturing environments where speed, reliability, and environmental considerations are paramount. Unlike traditional adhesives that may require heat, solvents, or extended curing times, UV cure anaerobic variants offer on-demand curing, making them ideal for high-throughput production lines.

The concept of anaerobic adhesives dates back to the mid-20th century, initially developed for threadlocking and sealing applications in mechanical assemblies. These materials cure in the absence of oxygen, typically when confined between metal surfaces. The integration of UV curing, which involves exposure to specific wavelengths of light, adds a layer of control and efficiency. This dual-cure mechanism allows for immediate fixturing via UV light, followed by full polymerization in shadowed areas through anaerobic processes, addressing limitations of single-cure systems.

This comprehensive guide delves into the intricacies of UV cure anaerobic adhesives, starting from their fundamental formulation logic and extending to practical industrial applications. We will explore the chemical principles behind their design, manufacturing processes, key properties and advantages, real-world uses across sectors, and emerging trends shaping their future. By understanding these elements, engineers, manufacturers, and researchers can better leverage these adhesives to optimize performance, reduce costs, and enhance product durability. As industries push toward sustainability and automation, UV cure anaerobic adhesives stand out as a pivotal tool in modern materials science.

The guide is structured to provide a logical progression: from the molecular building blocks to end-user benefits. Whether you’re a novice seeking an overview or a seasoned professional looking for in-depth insights, this article aims to equip you with actionable knowledge. With a focus on practical implications, we’ll highlight how these adhesives bridge the gap between laboratory innovation and industrial scalability.

Overview of UV Cure Anaerobic Adhesives

UV cure anaerobic adhesives are hybrid materials that combine the rapid curing capabilities of UV-sensitive compounds with the oxygen-exclusion mechanism of anaerobic systems. At their core, these adhesives remain liquid until triggered by either UV light exposure or the absence of air in the presence of metal ions, such as those found on iron or copper surfaces.This dual functionality distinguishes them from pure UV adhesives, which require direct light access for curing, or standard anaerobic adhesives, which may take hours to fully set.

Chemically, these adhesives are typically based on acrylic or methacrylate monomers, which polymerize to form strong, cross-linked networks. The UV component allows for “cure-on-demand,” where parts can be assembled and instantly fixed with light, enabling immediate handling and quality checks. In areas shielded from light—such as deep crevices or opaque substrates—the anaerobic pathway takes over, ensuring complete bonding without voids or weaknesses.

Historically, anaerobic adhesives were pioneered by companies like Loctite in the 1950s for locking fasteners and sealing pipes. The addition of UV curing emerged in the late 20th century to address production bottlenecks, particularly in electronics and medical device assembly where speed is critical. Products like Permabond UV7141 and Loctite AA 352 exemplify this category, offering high viscosity for gap-filling and resistance to chemicals and humidity.

In practice, these adhesives are dispensed as one-part systems, eliminating the need for mixing and reducing waste. They are non-toxic, low-odor, and compliant with many regulatory standards, making them suitable for sensitive applications. However, their effectiveness depends on proper surface preparation, as contaminants like oils can inhibit curing. Overall, UV cure anaerobic adhesives provide a versatile solution for bonding diverse materials, from metals and glass to plastics, in environments demanding both speed and strength.

Formulation Logic of UV Cure Anaerobic Adhesives

The formulation of UV cure anaerobic adhesives is a sophisticated balance of chemistry, designed to achieve stability in storage while enabling rapid, reliable curing under specific conditions. At the heart of these formulations are polymerizable monomers, typically dimethacrylates or acrylates, which serve as the backbone for the cured polymer network. These monomers are chosen for their low viscosity, allowing easy dispensing, and their ability to form durable cross-links.

For the anaerobic curing pathway, the formulation includes a hydroperoxide initiator, such as cumene hydroperoxide, which decomposes in the absence of oxygen to generate free radicals. An accelerator, often benzoic sulfimide (saccharin) or amine-based compounds, enhances the reaction rate by facilitating metal ion catalysis from substrates like copper or iron. This logic ensures curing only occurs when the adhesive is sandwiched between surfaces, preventing premature polymerization.

The UV curing aspect introduces photoinitiators, such as benzophenone or phenylglyoxylate derivatives, which absorb UV light (typically 365-405 nm) and initiate radical or cationic polymerization. Cationic systems, using onium salts, are particularly useful for deeper cures and better adhesion to challenging substrates. To stabilize the blend, inhibitors like quinones are added to scavenge stray radicals during storage, ensuring shelf life of up to a year.

Additives play a crucial role in tailoring properties. Thickeners like fumed silica control viscosity, while plasticizers enhance flexibility. For enhanced performance, toughening agents such as rubber particles can be incorporated to improve impact resistance. The logic behind these choices is driven by end-use requirements: for example, medical-grade formulations prioritize biocompatibility, omitting certain accelerators.

Balancing the dual-cure mechanisms is key; too much photoinitiator might cause surface tackiness, while excess hydroperoxide could lead to incomplete UV cures. Formulation development often involves iterative testing, using differential scanning calorimetry to monitor reaction kinetics. Green chemistry principles are increasingly applied, replacing hazardous components with bio-based alternatives to reduce environmental impact. Ultimately, the formulation logic revolves around achieving a stable, multi-functional system that cures efficiently via either pathway, optimizing for strength, speed, and substrate compatibility.

Manufacturing Process of UV Cure Anaerobic Adhesives

Manufacturing UV cure anaerobic adhesives requires precise control to prevent premature curing while ensuring batch consistency. The process begins with raw material selection and quality checks, where monomers, initiators, and additives are verified for purity to avoid impurities that could destabilize the formulation.

Mixing occurs in inert atmospheres, often under nitrogen, to exclude oxygen and light. High-shear mixers blend the acrylate monomers with photoinitiators and anaerobic components sequentially: first, dissolve the accelerators and inhibitors, then add hydroperoxides last to minimize reactivity. Temperature is maintained below 40°C to prevent thermal initiation.

Filtration removes particulates, followed by deaeration to eliminate dissolved oxygen, enhancing stability. Packaging in opaque, air-tight containers—such as squeeze bottles or cartridges—protects against UV exposure and air ingress.

Quality control involves viscosity testing, cure speed assessments using UV lamps or metal fixtures, and accelerated aging studies. Automation in modern facilities minimizes human error, with inline monitoring for real-time adjustments. Sustainable practices, like solvent-free processing, are increasingly adopted to align with environmental regulations.

The end result is a ready-to-use product that integrates seamlessly into assembly lines, where curing is initiated post-dispensing via UV sources or confinement.

Properties and Advantages of UV Cure Anaerobic Adhesives

UV cure anaerobic adhesives exhibit a unique set of properties that make them superior in many scenarios. Mechanically, they offer high shear strength (up to 20 MPa) and excellent gap-filling capabilities, with viscosities ranging from 100 to 50,000 cP. Thermally, they withstand temperatures from -50°C to 150°C, and chemically resist solvents, oils, and humidity.

Advantages include rapid curing: UV exposure achieves fixture in seconds, while anaerobic full cure occurs in 24 hours. This speed boosts productivity and reduces energy use compared to heat-cured alternatives. Cure-on-demand prevents waste, and the single-part nature simplifies application.

They provide low odor and toxicity, enhancing workplace safety, and enable bonding of dissimilar materials without primers in many cases. Compared to epoxies, they offer better vibration resistance, ideal for dynamic loads. Drawbacks include dependency on clean surfaces and limited depth cure without anaerobics, but overall, their versatility outweighs these.

Industrial Applications of UV Cure Anaerobic Adhesives

In automotive manufacturing, these adhesives secure fasteners and seal engine components, providing vibration resistance and instant handling. Aerospace applications include bonding composites and metals in airframes, where lightweight and durable joins are essential.

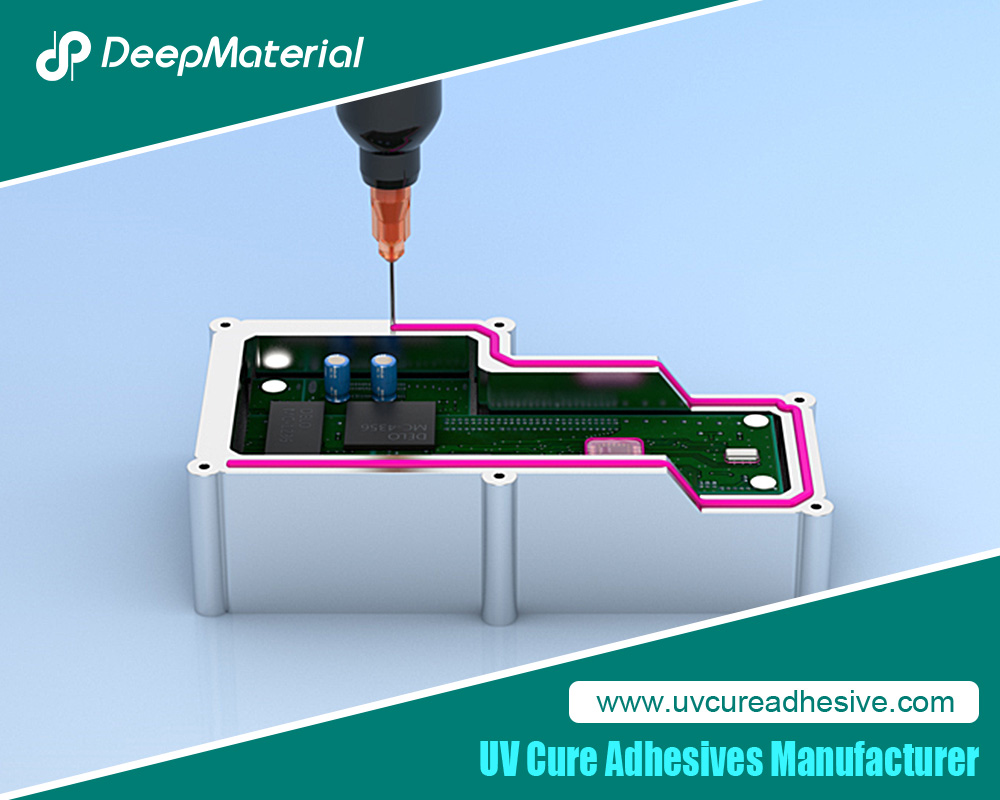

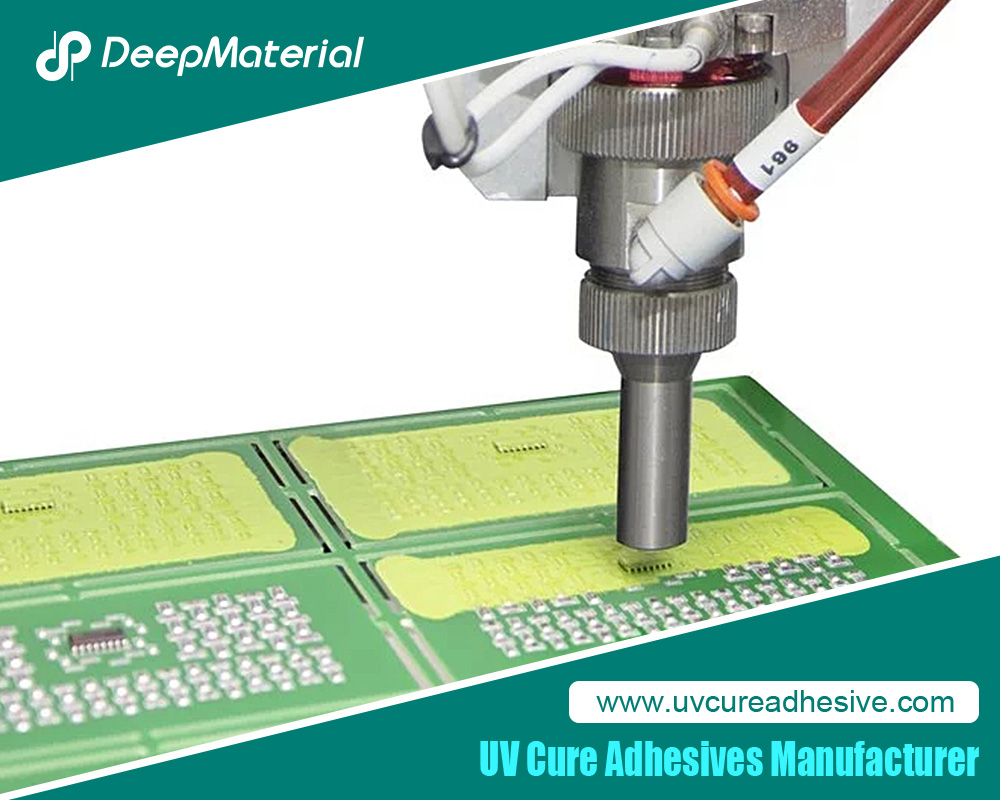

Electronics benefit from precise dispensing for circuit board assembly, encapsulating components against moisture. In medical devices, they assemble syringes and catheters, ensuring sterility and biocompatibility.

Glass bonding in furniture and architecture uses them for seamless, invisible joins. Industrial machinery employs them for valve and conveyor assembly, enhancing reliability. Pressure-sensitive films and loudspeakers also leverage their quick cure for high-volume production.

Case studies show reduced downtime in automotive lines and improved yields in electronics, underscoring their practical value.

Future Trends in UV Cure Anaerobic Adhesives

Looking ahead, advancements focus on eco-friendly formulations using bio-based monomers to minimize VOCs. Smart adhesives with self-healing or sensor-integrated properties are emerging for IoT applications.

Faster curing via LED-optimized photoinitiators and enhanced thermal stability will expand uses in 3D printing and high-tech sectors. Market growth is projected at 6-9% CAGR, driven by demand in EVs and medical tech. Compatibility with diverse substrates and automation will further propel adoption.

Conclusion

UV cure anaerobic adhesives embody innovation in bonding technology, offering a blend of speed, strength, and versatility from formulation to application. As industries evolve, their role in sustainable manufacturing will only grow, promising enhanced efficiency and reliability.

For more about a complete guide to UV cure anaerobic adhesive: from formulation logic to industrial applications, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.