In – depth Analysis of the Main Characteristics of UV Adhesives for Touch Screens

In the manufacturing of modern electronic devices, the touch screen serves as a crucial component for human – machine interaction, and its performance and quality are of utmost importance. As a key material for effectively bonding various components of the touch screen, the characteristics of UV adhesives for touch screens play a decisive role in the overall performance of the touch screen. This article will conduct an in – depth exploration of the main characteristics of UV adhesives for touch screens.

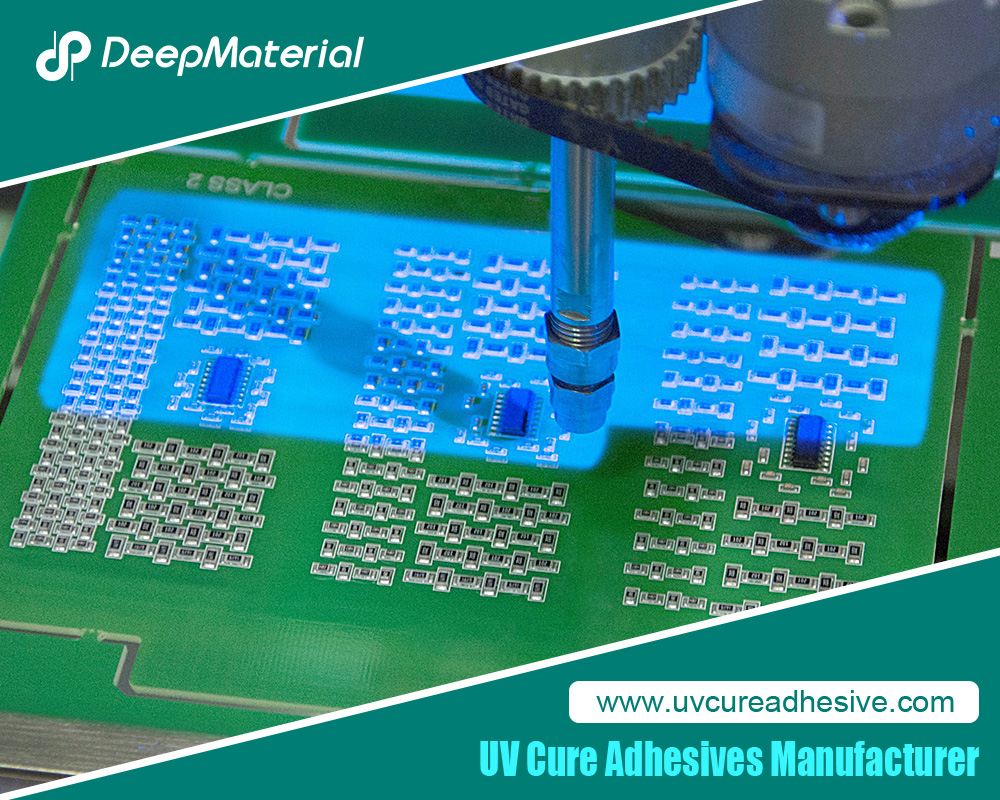

Rapid Curing Property

One of the most remarkable characteristics of UV adhesives for touch screens is their rapid curing ability. Under ultraviolet (UV) light irradiation, the photoinitiators in the UV adhesive absorb the energy of UV light and rapidly generate active free radicals or cations, initiating polymerization, cross – linking, and grafting chemical reactions. As a result, the adhesive can transform from a liquid state to a solid state within just a few seconds to tens of seconds. Take the mobile phone touch screen bonding process on an automated production line as an example. Traditional adhesives may take several minutes or even longer to cure, which seriously affects production efficiency. In contrast, UV adhesives can complete the curing process in a few seconds by virtue of their rapid curing property, greatly improving production efficiency and enabling the production line to operate at high speed to meet the needs of mass production. This rapid curing property also allows for immediate product inspection and handling after curing, saving production space and time costs.

High Transparency

The display effect of the touch screen is directly related to the user experience, and the high transparency of UV adhesives ensures that they will not interfere with the display. High – quality UV adhesives for touch screens usually have a light transmittance of over 98% after curing, which is close to the light – transmitting performance of optical glass. They hardly absorb or scatter light, thus ensuring that the images displayed on the touch screen are clear, with vivid colors and high contrast. Whether in strong light or low – light environments, they can present the best visual effects for users. For example, when using a mobile phone in outdoor sunlight, the high – transparency UV adhesive can make the screen content still clearly visible without blurring or color distortion. This characteristic is particularly important for high – end display devices such as OLED displays and high – resolution tablet touch screens, which have extremely high requirements for display accuracy and visual effects.

High – Strength Bonding

Touch screens are subject to various external forces during daily use, such as pressing, collision, and friction. Therefore, UV adhesives need to have high – strength bonding performance. After curing, UV adhesives can form strong chemical bond connections and have high bonding strength, which can withstand various pressures and impacts on the touch screen during use, ensuring the stability and reliability of the display. In mobile phone drop tests, even if the casing is damaged to a certain extent, due to the high – strength bonding of UV adhesives, the touch screen can still remain tightly connected to other components without problems such as degumming or delamination, effectively ensuring the normal use of the touch screen. Moreover, this high – strength bonding performance can also maintain long – term stability, and the bonding force will not decrease significantly even after long – term use and environmental changes.

Good Flexibility

Touch screens are often composed of multiple components made of different materials, such as glass, plastic, and metal, which have different coefficients of thermal expansion. When the temperature changes, the expansion and contraction degrees of each component are different. If the UV adhesive does not have good flexibility, stress concentration is likely to occur at the interface, leading to degumming or damage. UV adhesives for touch screens have good flexibility, which can buffer the stress caused by the difference in thermal expansion coefficients to a certain extent and avoid bonding failure due to stress concentration. At the same time, good flexibility also enables the UV adhesive to better adapt to the micro – undulations of different material surfaces during the bonding process, forming a tighter and more uniform bonding layer and further improving the bonding effect. For example, in the application of foldable screens, the flexibility of UV adhesives can ensure good bonding during the repeated folding and unfolding of the screen.

Excellent Aging Resistance

Electronic devices usually need to be used in various environments for a long time, so UV adhesives for touch screens must have excellent aging resistance. They should be able to resist the erosion of environmental factors such as ultraviolet light, temperature changes, humidity, and chemical substances, and not undergo phenomena such as yellowing, whitening, and embrittlement for a long time. After years of actual use, touch screens using high – quality UV adhesives can still maintain good appearance and performance without affecting the display effect and bonding strength due to aging. In the application of touch screens for outdoor billboards, which are long – term exposed to sunlight and harsh climatic conditions, UV adhesives with good aging resistance can ensure that the touch screens work normally for several years, reducing maintenance and replacement costs.

Low Shrinkage Rate

During the curing process of UV adhesives, the shrinkage rate is a key indicator. UV adhesives with a low shrinkage rate have small volume changes during curing, which can avoid deformation or damage to touch screen components caused by internal stress generated by shrinkage. If the shrinkage rate of the UV adhesive is large, it may cause problems such as warping of the touch screen and the appearance of dark spots or bright spots in the display area, which seriously affect product quality. On the other hand, low – shrinkage UV adhesives can make each component of the touch screen maintain good flatness and relative position accuracy after curing, ensuring the consistency and stability of the display effect. This is particularly important for large – size touch screens, as large – size screens are more sensitive to deformation.

Good Moisture Resistance

Touch screens are often used in humid environments, such as touch screens of smart mirrors in bathrooms and electronic devices used in outdoor rain. UV adhesives for touch screens have good moisture resistance, which can effectively prevent the intrusion of moisture and avoid problems such as bonding failure, corrosion, and decline in electrical performance caused by moisture. Even when used in high – humidity environments for a long time, UV adhesives can still maintain the stability of their bonding strength and other properties. Through special formulation design and synthesis processes, the molecular structure of UV adhesives is made tight, making it difficult for water molecules to penetrate, thus ensuring the reliable operation of touch screens in humid environments.

Neutral Formula

The ITO (Indium Tin Oxide) coating in touch screens is relatively sensitive to chemical substances such as acids and alkalis and is easily corroded, which affects the touch performance and service life of the touch screen. UV adhesives for touch screens use a neutral formula and do not contain corrosive chemical substances, so they will not damage the ITO coating, ensuring the long – term stable operation of the touch screen. Throughout the entire life cycle of the touch screen, the neutral formula of the UV adhesive can maintain the integrity and performance of the ITO coating, ensuring that the touch sensitivity and accuracy of the touch screen remain consistent.

Superior Electrical Performance

As an input component of electronic devices, the touch screen needs to have good electrical connections and signal transmission with internal circuits. UV adhesives for touch screens have superior electrical performance, such as high insulation resistance, low dielectric constant, and low dielectric loss, which will not interfere with or attenuate the electrical signals of the touch screen, ensuring the calculation speed and signal transmission accuracy of the touch screen during long – term use. In the application of touch screens for high – frequency signal transmission, the excellent electrical performance of UV adhesives can ensure the stable transmission of signals and avoid problems such as signal distortion and delay.

Low Hardness for Easy Rework

During the production and maintenance of touch screens, it is sometimes necessary to disassemble and reassemble the bonded components. The low hardness of UV adhesives for touch screens makes rework relatively easy. When rework is required, the bonded components can be separated more conveniently without causing too much damage to the components, reducing maintenance costs and the scrap rate. Compared with adhesives with high hardness, low – hardness UV adhesives have more advantages in rework and can improve the maintainability of products.

For more about the best in – depth analysis of the main characteristics of UV adhesives for touch screens, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.