UV Cure Polyurethane Adhesive: A Key Component in Durable Medical Equipment

UV Cure Polyurethane Adhesive is a special kind of glue that’s really important for making medical equipment. It’s a flexible glue that works really well for a lot of different uses. What makes it stand out is that it sets hard when it gets hit by ultraviolet (UV) light. This quick setting makes it stick super strong and fast, which is perfect for making medical devices.

In the world of healthcare, glue is key for putting together medical equipment. It holds all the parts together so everything works right and lasts a long time. Imagine trying to build complex devices for patient care without good glue—it would be super tough! That’s why UV Cure Polyurethane Adhesive is getting more and more popular for making medical gear because of the special things it can do.

Importance of Durable Medical Equipment in Healthcare

Durable Medical Equipment (DME) is like wheelchairs, hospital beds, and walkers that people use over and over to help them feel better or live more easily with certain conditions. DME is super important because it helps folks with disabilities or long-term health issues do everyday things on their own, move around easier, and be more comfortable.

In places like hospitals, clinics, and at home, both patients and healthcare workers rely on this equipment. It helps with lots of medical care needs, rehab exercises, and even just day-to-day living. Without DME, giving top-notch care to folks who need it would be way harder.

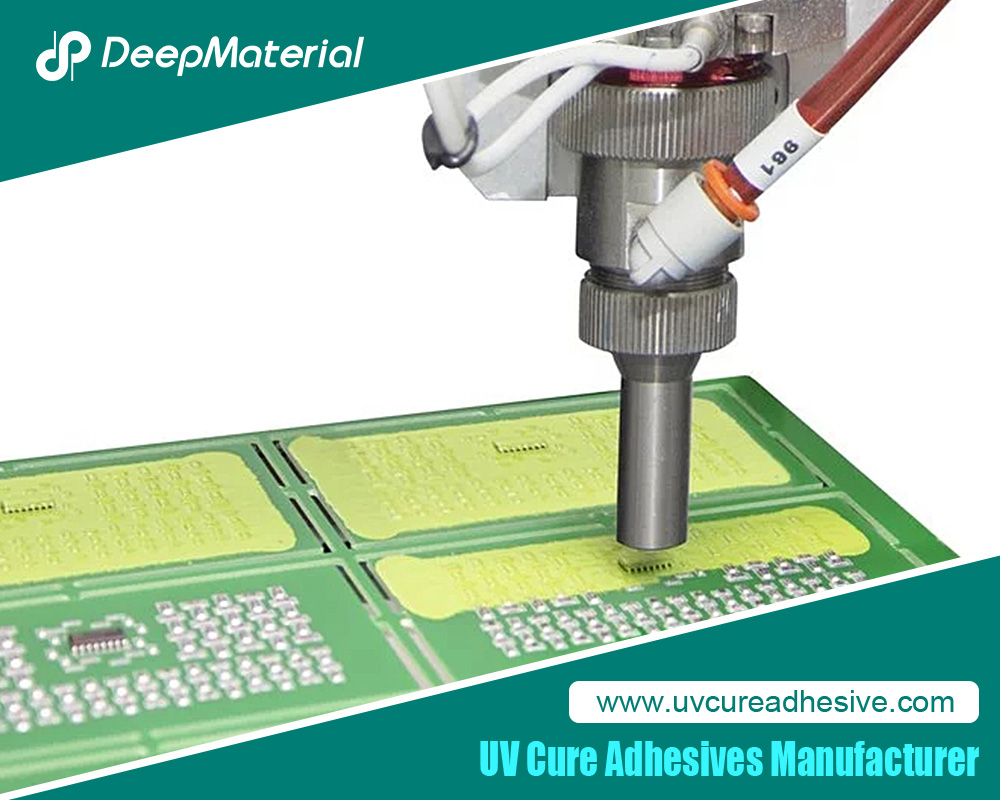

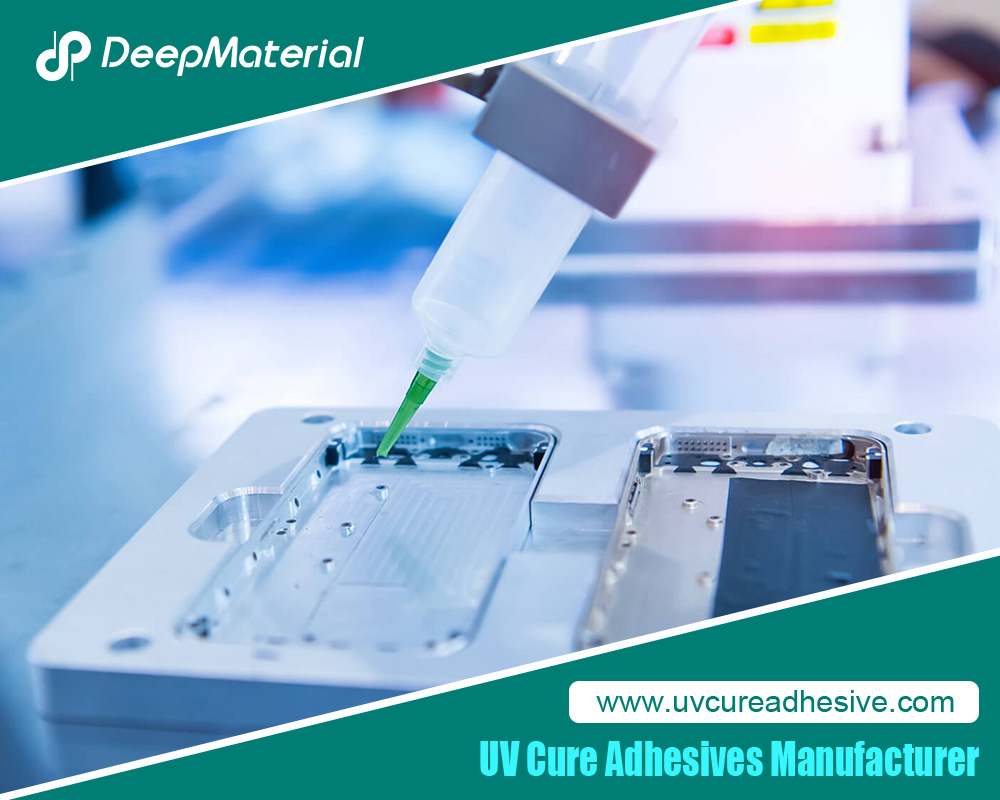

Role of Adhesives in Medical Equipment Manufacturing

When it comes to making medical equipment, glue is a big deal. It sticks different materials together so everything stays solid and works like it should. The glue has to be really strong to deal with daily use and all kinds of weather and temperatures.

There are lots of glues out there for making medical gear, like epoxy, acrylic, silicone, and polyurethane glues. Each kind has its own special features and perks, so choosing the right one depends on what the equipment needs to do.

Advantages of UV Cure Polyurethane Adhesive over Traditional Adhesives

A big plus for UV Cure Polyurethane Adhesive compared to old-school glues is it sets super fast. Usually, traditional glues take a long time—sometimes even days—to dry completely. But with UV Cure Polyurethane Adhesive, it’s ready in just seconds with some UV light. This speed boost means making medical tech is quicker and more efficient.

It also sticks things together really strongly. This strong bond means medical equipment lasts longer and is more reliable, which is super important when you need equipment to be really tough and handle a lot of use.

Another thing about UV Cure Polyurethane Adhesive is it’s great at dealing with chemicals and big temperature changes. It can handle being cleaned with harsh things and doesn’t get weak in hot or cold places. This is perfect for medical tools that need to be super clean or used in different conditions.

How UV Cure Polyurethane Adhesive Works

UV Cure Polyurethane Adhesive sets through a process called photopolymerization. This means when it gets hit with UV light, it starts a chemical reaction that makes it hard and strong. The UV light kicks off this process by activating special parts in the glue called photoinitiators.

A few things can change how well and how fast the glue sets. The power of the UV light, how deep the glue layer is, and the type of light used can make a difference in how strong and quick the bond is. It’s important to get these things just right to make sure the glue does its job well.

Types of Medical Equipment that Use UV Cure Polyurethane Adhesive

Because UV Cure Polyurethane Adhesive has so many benefits, it’s used in loads of different medical tools. Things like catheters, bandages for wounds, surgical tools, and fake limbs all use this adhesive.

For catheters, the glue makes sure all the parts stay together without any leaks. Its quick drying time is a big help in making these important medical tools fast.

For bandages, the glue helps them stick on properly, keeping wounds safe from germs and helping them heal right. The strong bond means the bandage won’t fall off easily, even if you move around a lot.

Surgical tools and fake limbs need to be really sturdy and reliable. UV Cure Polyurethane Adhesive gives them the tough bond they need to work well and help patients.

Benefits of UV Cure Polyurethane Adhesive in Medical Equipment

Using UV Cure Polyurethane Adhesive when making medical equipment brings a lot of pluses. A big benefit is that it makes things last longer. Since the glue is so strong, equipment can be used many times without breaking down. This means hospitals and clinics save money because they don’t have to fix or replace things as often.

This type of glue is also really tough against wear and tear. It can handle a lot of bending, twisting, and getting knocked around. So, medical tools work reliably over time, which means less chance they’ll suddenly stop working when needed.

Plus, this glue helps cut down on how much it costs to keep equipment in good shape. Because it makes such a sturdy bond, things don’t need fixing as much. This saves money and means equipment is ready to use more often, without long waits for repairs.

UV Cure Polyurethane Adhesive and Sterilization

Keeping medical tools clean and germ-free is super important, and UV Cure Polyurethane Adhesive can handle the cleaning processes used in hospitals, like autoclaving or using special gas.

But, it’s important to clean things the right way to make sure the glue stays strong. Too much UV light during cleaning could weaken the glue, so it’s key to get the cleaning conditions just right. This means paying attention to how long and how intensely equipment is cleaned to keep everything safe without hurting the glue.

Safety Considerations when Using UV Cure Polyurethane Adhesive in Medical Equipment

While UV Cure Polyurethane Adhesive is great for lots of reasons, it’s important to be careful when using it. Handling any kind of glue can be risky if you don’t take the right safety steps.

For instance, the glue could irritate your skin or eyes, so wearing gloves and safety goggles is a smart move. Making sure the area is well-ventilated is also important to avoid breathing in any fumes.

And, just like with any materials used in making things, it’s important to follow the instructions on how to store and get rid of any glue you don’t use, to keep people and the environment safe.

UV Cure Polyurethane Adhesive as a Key Component in Durable Medical Equipment

In conclusion, UV Cure Polyurethane Adhesive is super important for making long-lasting medical equipment. Its special features and benefits make it perfect for sticking different parts together, making sure the equipment is tough and works well.

This glue has some big pluses compared to older glues, like setting really quickly, forming a very strong bond, and being able to handle harsh chemicals and big temperature changes well. It’s used in all kinds of medical technology, including catheters, bandages for wounds, tools for surgery, and artificial limbs.

For more about choosing a comprehensive guide to UV Cure Polyurethane Adhesive, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.