Exploring the Environmental Performance of UV Glue and Strategies for Optimizing Odor and VOC Content

UV glue, as an adhesive that achieves rapid curing through ultraviolet (UV) light irradiation, has been widely applied in numerous fields such as electronics, optics, healthcare, and automobiles, thanks to its advantages of fast curing speed, high bonding strength, and good environmental performance. With the continuous enhancement of environmental awareness and the increasing strictness of environmental protection regulations, whether the chemical components of UV glue comply with environmental protection regulations such as RoHS and REACH, and how to reduce its irritating odor and volatile organic compound (VOC) content have become the focus of attention within the industry. In-depth research on these issues is of great significance for promoting the sustainable development of UV glue and expanding its application scope.

Analysis of the Main Chemical Components of UV Glue

The composition of UV glue is relatively complex and usually consists of prepolymers, monomers, photoinitiators, and a small amount of additives, each of which plays a unique and crucial role in the performance of the glue.

- Prepolymers: Prepolymers are the core components of UV glue, providing the basic physical properties of the cured adhesive layer, such as hardness, flexibility, and strength. Common types include epoxy acrylates, urethane acrylates, polyether acrylates, and polyester acrylates. Epoxy acrylates contain polar groups such as hydroxyl, ether, and ester groups in their molecules, which can generate strong interaction forces with the molecules of the bonded materials, resulting in excellent bonding performance, as well as good electrical and heat resistance. Urethane acrylates combine the flexibility, abrasion resistance, aging resistance, and high tear strength of polyurethanes with the good weather resistance and excellent optical properties of acrylates. The selection of different types of prepolymers directly affects the applicability of UV glue in specific application scenarios.

- Monomers: Monomers, also known as reactive diluents, mainly serve to adjust the viscosity of the glue to make it easy for construction operations. They also participate in the polymerization reaction and have an important impact on the performance of the cured adhesive layer. According to the functionality, they can be divided into monofunctional monomers, difunctional monomers, and multifunctional monomers. Monofunctional monomers help improve the flexibility and adhesion of the adhesive layer, while difunctional and multifunctional monomers not only act as diluents but also serve as crosslinkers, affecting the hardness, toughness, and strength of the adhesive layer. Increasing the functionality of monomers can accelerate the curing process. In actual production, mixtures of monomers with different functionalities are often used to meet different performance requirements. Common monomers include butyl acrylate, isooctyl acrylate, dipropylene glycol diacrylate, etc.

- Photoinitiators: Photoinitiators are key components of the UV curing system and play a decisive role in the curing rate. Under UV light irradiation, photoinitiators absorb photon energy to generate active free radicals or cations, which initiate the polymerization and crosslinking reactions of monomers and prepolymers. Free radical photoinitiators such as 1173, 184, 907, and benzophenone are widely used. Different photoinitiators have different absorption wavelengths and initiation efficiencies for UV light, so they need to be reasonably selected according to the characteristics of the UV light source and the curing requirements of the glue.

- Additives: Although the amount of additives added is relatively small, they can significantly improve certain properties of UV glue. For example, antioxidants can prevent the glue from deteriorating due to oxidation during storage and use, prolonging its service life; stabilizers help improve the stability of the glue under different environmental conditions; coupling agents can enhance the chemical bonding between the glue and the surface of the bonded material, improving the bonding strength. In addition, there are additives such as leveling agents and plasticizers, which can respectively improve the coating performance and flexibility of the glue.

Investigation of the Compliance of UV Glue with RoHS and REACH Regulations

- RoHS Regulation: The RoHS (Restriction of Hazardous Substances) regulation, that is, the directive on the restriction of the use of hazardous substances, aims to limit the use of hazardous substances such as lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs) in electrical and electronic equipment. UV glue that complies with the RoHS regulation strictly controls the content of the above-mentioned hazardous substances during the production process to ensure that it will not cause harm to human health and the environment when applied in electronic products and other fields. Some high-quality UV glues select raw materials free of these hazardous substances and optimize the production process to ensure that the content of hazardous substances in the finished product is lower than the limit value specified by the regulation, thus obtaining the RoHS certification, which provides a guarantee for its wide application in the electronics field.

- REACH Regulation: The REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation is a regulation in the European Union for the preventive management of all chemicals entering its market. This regulation requires enterprises to evaluate the safety of chemicals and register relevant information with the European Chemicals Agency (ECHA). For UV glue, manufacturing enterprises need to confirm whether its chemical components contain substances of very high concern (SVHC). If it contains SVHC and the content exceeds 0.1% (mass fraction), it is necessary to fulfill obligations such as notification or authorization. Some UV glue manufacturers ensure that the prepolymers, monomers, photoinitiators, and additives they use do not contain or only contain trace amounts of SVHC through strict screening of raw material suppliers to meet the requirements of the REACH regulation.

- Regulatory Compliance Testing and Certification: Third-party testing institutions play an important role in ensuring that UV glue complies with regulations such as RoHS and REACH. These institutions use advanced testing equipment and scientific testing methods to comprehensively analyze and test UV glue. Common testing methods include inductively coupled plasma mass spectrometry (ICP-MS) for detecting the content of heavy metals, and gas chromatography-mass spectrometry (GC-MS) for analyzing organic compounds. After passing the testing, if the product meets the regulatory requirements, the testing institution will issue the corresponding certification certificate. When selecting UV glue, enterprises should require suppliers to provide relevant testing reports and certification certificates to ensure the compliance of the product.

Analysis of the Sources of the Irritating Odor and VOC Content in UV Glue

- Sources of Irritating Odor: The irritating odor of UV glue mainly comes from the monomers and photoinitiators in its components. Some acrylate monomers have certain volatility. During the curing process of the glue, they volatilize into the air, producing a pungent odor. For example, some low-molecular-weight acrylate monomers, such as methyl acrylate and ethyl acrylate, have strong volatility and are likely to cause discomfort in the respiratory tract. When photoinitiators absorb UV light and undergo photochemical reactions, they may also produce some by-products with irritating odors. In addition, if the additives in the glue formula are not properly selected, the volatilization of certain additives may also exacerbate the odor problem.

- Sources of VOC Content: VOCs (Volatile Organic Compounds) in UV glue mainly come from monomers and solvents (if contained in the formula). Monomers, as reactive diluents, will volatilize as VOCs and be emitted into the atmosphere when they do not fully participate in the polymerization reaction. Although UV glue uses less or even no solvents compared with traditional solvent-based adhesives, the volatilization of monomers still results in a certain VOC content. In some early UV glues, a small amount of organic solvents may be added to improve the construction performance, which will also increase the VOC emissions.

Strategies for Reducing the Irritating Odor and VOC Content in UV Glue

- Optimizing the Formula Design

- Selecting Low-Odor Monomers and Photoinitiators: Researching, developing, and selecting new types of low-odor and low-volatility monomers and photoinitiators is the key to reducing the odor and VOC content. For example, a new generation of acrylate monomers, through molecular structure modification, has reduced volatility and irritation while maintaining good reactivity. Some new photoinitiators not only have high initiation efficiency but also produce fewer irritating by-products during the curing process.

- Adjusting the Proportions of Prepolymers, Monomers, and Photoinitiators: Through experiments, optimize the proportions of these three components to enable monomers to participate in the polymerization reaction as fully as possible while ensuring the curing performance, and reduce the volatilization of unreacted monomers. Reasonably adjust the dosage of photoinitiators to avoid more side reactions caused by excessive use, which may generate more irritating substances.

- Adding Deodorants and Anti-Volatility Additives: Add an appropriate amount of deodorants to the glue formula, such as some compounds with functions of adsorbing or neutralizing odors, which can effectively reduce the irritating odor. At the same time, add anti-volatility additives to inhibit the volatilization of monomers, thereby reducing the VOC content. These additives need to have good compatibility with other components of the glue and should not affect the curing performance and bonding strength of the glue.

- Improving the Production Process

- Optimizing the Synthetic Process Conditions: Precisely control the reaction temperature, time, and catalyst dosage during the synthesis process of prepolymers to improve the quality and stability of prepolymers, reduce the generation of impurities, and thus reduce the odor problem caused by the volatilization of impurities. In the synthesis or purification process of monomers, use advanced separation technologies to remove impurities that may cause odor and high VOC emissions.

- Adopting Advanced Mixing and Dispersion Technologies: In the glue preparation process, use efficient mixing and dispersion equipment to evenly disperse all components, improve the uniformity and completeness of the reaction. This helps to reduce the volatilization problem caused by the excessively high local monomer concentration and ensures the uniform distribution of photoinitiators, improving the curing efficiency and reducing the odor and unreacted monomers caused by incomplete curing.

- Control Measures During the Use Process

- Strengthening Ventilation and Air Exchange: Install good ventilation equipment, such as exhaust fans and ventilation ducts, in the places where UV glue is used to timely discharge the irritating gases and VOCs that volatilize into the air outdoors, reducing the concentration of harmful gases indoors. This is a simple and effective method to reduce the impact of odor and VOCs on operators.

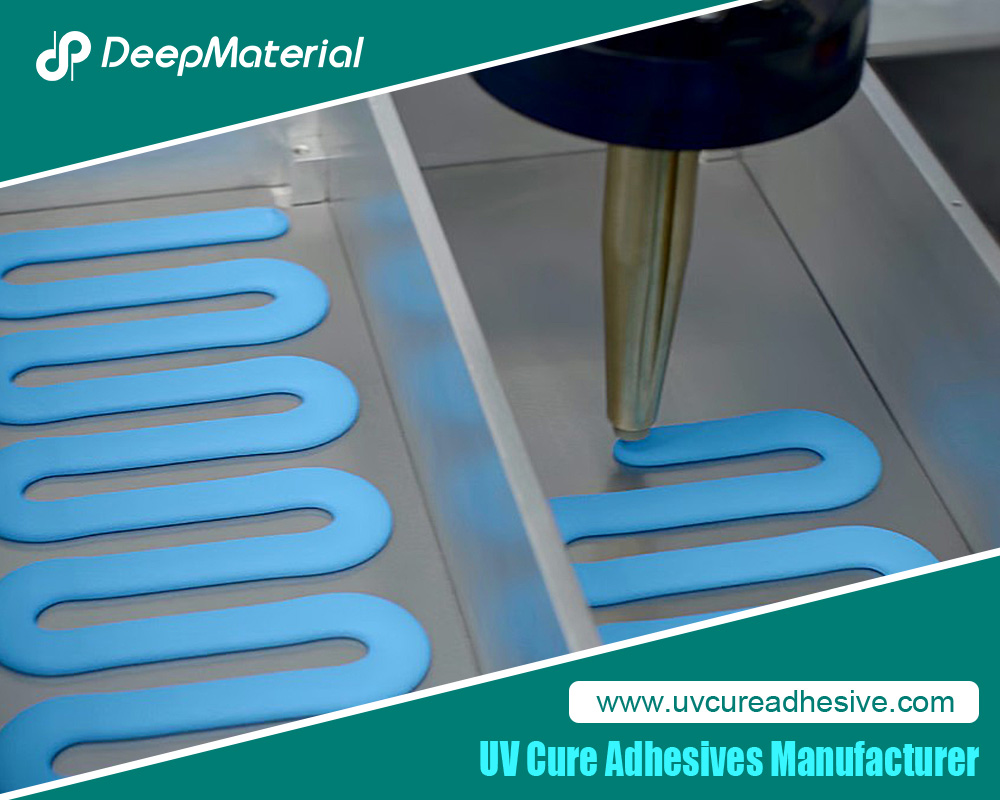

- Using Automated Dispensing and Curing Equipment: Automated equipment can accurately control the amount of glue used and the coating position, reducing the time and area of the glue exposed to the air, thereby reducing the volatilization amount. At the same time, automated curing equipment can better control the UV irradiation conditions to ensure the rapid and complete curing of the glue and reduce the volatilization of un-cured monomers.

- Operator Protection: Equip operators with appropriate protective equipment, such as masks, gloves, and goggles, to reduce their direct contact with irritating gases and glue, protecting the health of operators. At the same time, strengthen the training of operators so that they understand the characteristics and correct use methods of UV glue to avoid increased odor and VOC emissions caused by improper operation.

Research Cases and Practical Application Effects

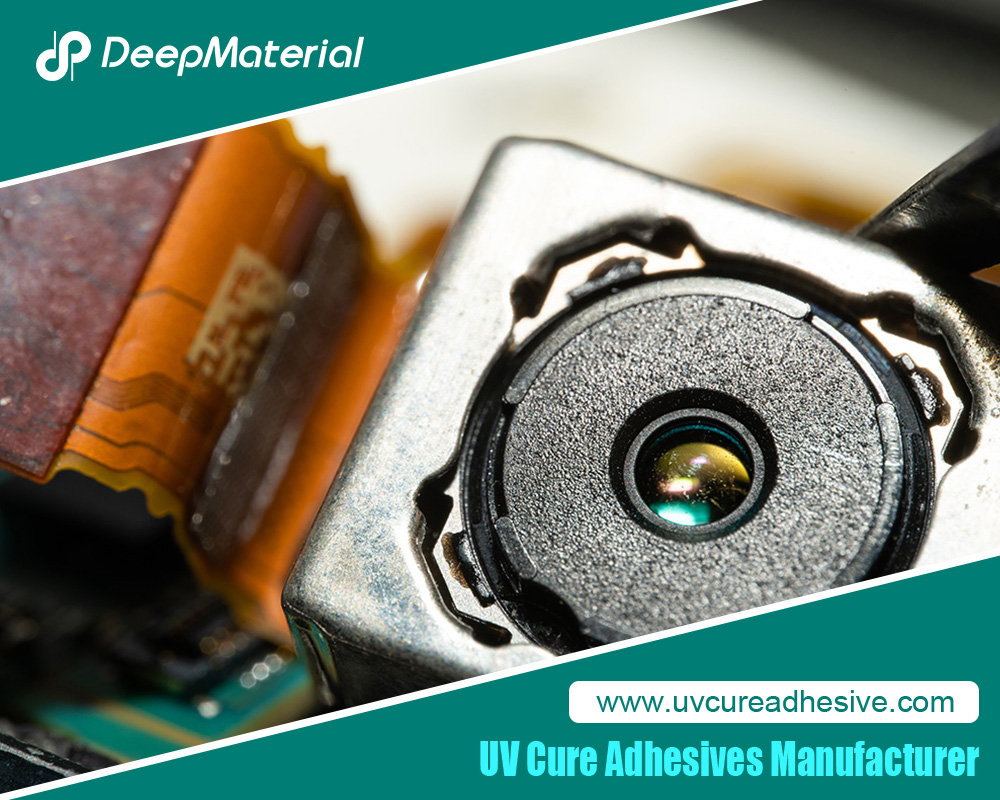

- Case of an Electronic Manufacturing Enterprise: This enterprise used UV glue in the assembly of mobile phone screens. The original glue had problems of a relatively large irritating odor and an excessive VOC content, which not only affected the working environment in the workshop but also faced the pressure of environmental protection inspections. Through cooperation with the glue supplier, the glue formula was optimized. New low-odor monomers were used to replace some traditional monomers, the types and dosages of photoinitiators were adjusted, and special deodorants and anti-volatility additives were added. At the same time, the ventilation system in the production workshop was upgraded, and automated dispensing and curing equipment was installed. After the improvement, the irritating odor of the glue was significantly reduced, the VOC content was reduced to meet the environmental protection standards, the working environment in the workshop was significantly improved, and the bonding quality and production efficiency of the products were not affected.

- Case of an Optical Device Manufacturer: In the bonding of optical lenses, the requirements for the optical performance and environmental protection performance of UV glue are extremely high. This factory selected a UV glue that claimed to be environmentally friendly, with low odor and low VOC content. However, in the initial stage of actual use, a slight irritating odor could still be smelled. After analysis, it was found that this was due to the uneven UV irradiation intensity of the curing equipment in the workshop, resulting in incomplete curing of some glue and the volatilization of unreacted monomers, which generated the odor. Subsequently, the factory debugged and upgraded the curing equipment to ensure uniform UV irradiation. At the same time, it further communicated with the glue supplier and fine-tuned the glue formula to improve its adaptability to different irradiation conditions. Finally, the odor problem was successfully solved, and the lenses were firmly bonded without affecting the optical performance, meeting the production requirements.

Conclusion and Outlook

As an indispensable adhesive in modern industry, the environmental performance of UV glue is of vital importance. From the perspective of chemical components, by rationally selecting and optimizing prepolymers, monomers, photoinitiators, and additives, UV glue can meet the requirements of environmental protection regulations such as RoHS and REACH. Regarding the problems of irritating odor and VOC content, through formula optimization, process improvement, and effective control measures during the use process, their impacts on the environment and human health can be significantly reduced. In the future, with the continuous improvement of environmental protection requirements and the continuous progress of technology, UV glue will develop in a more green, environmentally friendly, and high-performance direction. On the one hand, researchers will continue to explore new types of environmentally friendly raw materials to further reduce the odor and VOC content of the glue while improving its comprehensive performance. On the other hand, the production process will become more intelligent and refined, achieving more efficient production and lower environmental impact. In addition, with the continuous update of testing technologies, the testing of the environmental performance of UV glue will become more accurate and comprehensive, providing a more powerful guarantee for its quality control and regulatory compliance.

For more about exploring the environmental performance of UV glue and strategies for optimizing odor and VOC content, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.