The Environmental Benefits of Using UV Cure Adhesive Glue For Plastic To Plastic Instead of Traditional Methods

UV cure adhesive glue is a type of adhesive that sets or hardens when exposed to ultraviolet (UV) light. It’s a versatile and efficient solution that has become popular across various industries, including automotive, electronics, medical devices, and packaging, thanks to its unique properties.

This glue is particularly useful for bonding plastic components, which is essential for assembling durable and strong products, whether it’s in car interiors, electronic devices, or food packaging.

The Negative Impact of Traditional Plastic-to-Plastic Bonding Methods on the Environment

Traditional methods of bonding plastic typically involve using solvents or heat to melt and fuse the materials together. These methods, while effective, can harm the environment. Solvent-based adhesives release volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to workers. Heating plastics to bond them consumes energy, which increases carbon emissions and adds to climate change.

Additionally, these conventional bonding techniques often result in waste—excess adhesive and plastic scraps that aren’t always recyclable. This waste frequently ends up in landfills or incinerators, adding to pollution and resource depletion. These environmental and health concerns have spurred the search for more sustainable bonding alternatives.

How UV Cure Adhesive Glue Works

UV cure adhesive glue operates through a process called UV curing. This glue contains photoinitiators that react under UV light, triggering a chemical reaction that quickly hardens the adhesive. Unlike traditional methods, UV cure adhesive glue doesn’t require solvents or heat, making it a cleaner and more energy-efficient option.

The application process involves applying the adhesive to the plastic parts needing bonding, then exposing them to UV light. The light activates the photoinitiators, causing the glue to polymerize and create a strong bond between the plastic pieces. This process is not only cleaner but also very quick, often taking just seconds or minutes, depending on the adhesive’s formula and the UV light intensity.

Benefits Over Traditional Bonding Methods

UV cure adhesive glue offers several benefits over traditional bonding techniques. It eliminates the need for solvents and heat, which cuts down on energy use and prevents VOC emissions. The quick curing time also boosts productivity and efficiency in manufacturing settings, making it a smart choice for businesses looking to improve their operations while reducing their environmental impact.

The Environmental Benefits of UV Cure Adhesive Glue

The adoption of UV Cure Adhesive Glue brings numerous environmental benefits.

Reduced Carbon Footprint

Using energy-guzzling heat sources is a big no-no if we’re serious about cutting down greenhouse gas emissions—one of the main villains behind climate change. Ditching these energy hogs can make a serious dent in our carbon footprint and help cool down our warming planet.

Cutting back on energy use isn’t just good for Mother Earth; it also saves some green on energy bills. It’s a win-win move towards a sustainable future, ensuring our planet stays cleaner and healthier for the folks who’ll inherit it. By stepping up now and reducing our carbon footprint, we’re not just making a small change—we’re paving the way for a better tomorrow.

Reduced Waste

UV Cure Adhesive Glue steps up as an eco-friendly champ in the bonding game, creating way less waste compared to old-school methods. This glue is all about precision—you use just the right amount, no more, no less, which means no messy excess. Plus, it keeps the scraps clean, making them easy to recycle because the glue doesn’t mess up the plastic.

By cutting down on waste and making sure materials are recycled and reused, UV Cure Adhesive Glue is a top pick for anyone aiming to bond materials without bonding with guilt. It’s not just efficient and effective; it’s a step towards a more sustainable practice, keeping our planet a bit tidier.

Workers’ Safety

Using UV Cure Adhesive Glue isn’t just about sticking things together; it’s also about keeping the workplace safe. Traditional bonding methods often involve nasty solvents or require cranking up the heat, both of which can pose serious health risks. Workers exposed to these harsh conditions might experience respiratory issues, skin irritation, or other unpleasant health problems.

Switching to UV Cure Adhesive Glue means these hazardous conditions are dramatically reduced. This safer environment not only protects workers from health risks but can also boost morale and productivity. For companies, this is a chance to show they really care about their employees’ well-being, fostering a positive and safer work environment.

From a business standpoint, while UV Cure Adhesive Glue might need some upfront investment in UV curing equipment, the payoff in lower energy costs, less waste, and better productivity can really add up, making it a smart choice in the long run.

Applications of UV Cure Adhesive Glue

The use of UV Cure Adhesive Glue spans a wide range of industries, benefiting countless applications with its strong and quick-setting capabilities.

In the automotive industry, this adhesive is perfect for bonding parts like dashboards, door panels, and trim. It creates durable bonds that stand up to the daily wear and tear that cars go through.

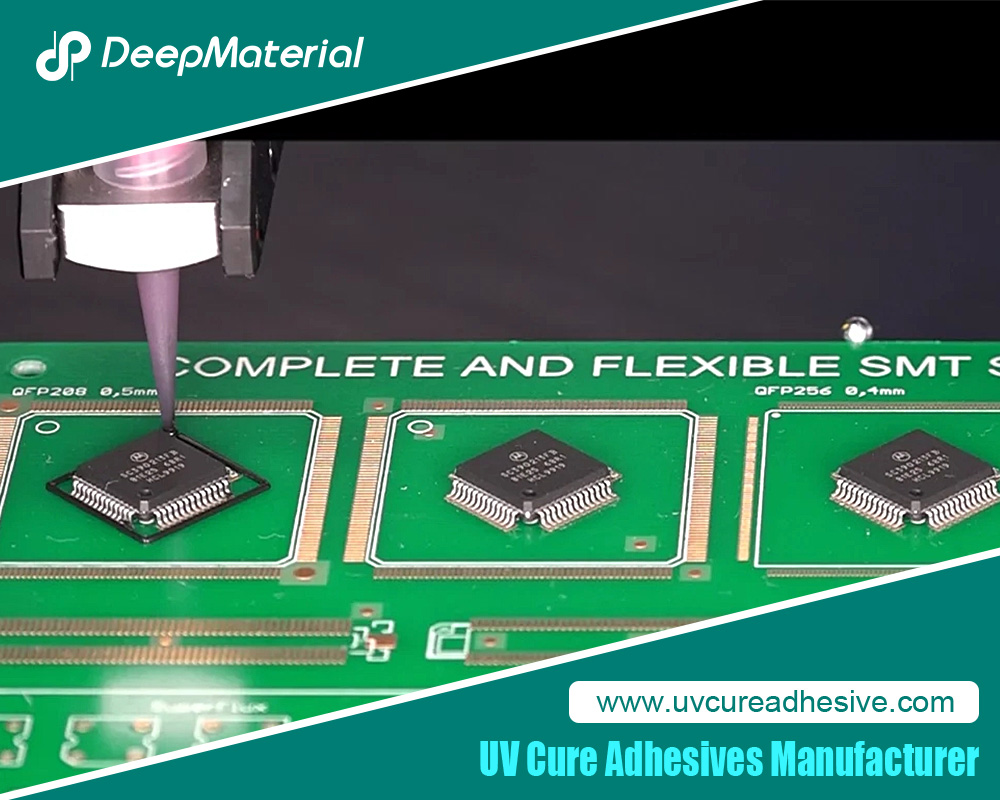

In the world of electronics, UV Cure Adhesive Glue helps put together circuit boards and secure components. It’s also great for encapsulating delicate electronic parts, protecting them while allowing for fast-paced assembly lines.

The medical devices industry also benefits from this versatile glue. It’s used to assemble parts of syringes, catheters, and surgical instruments. The glue’s biocompatibility and resistance to sterilization processes make it ideal for such critical applications.

Lastly, in the packaging industry, UV Cure Adhesive Glue is used to seal and bond plastic containers and packages. Its rapid curing time ensures packaging lines keep moving quickly while providing a strong seal that keeps contents safe and secure.

The Future of Sustainable Plastic Bonding

In conclusion, UV Cure Adhesive Glue brings a lot to the table for plastic bonding across various industries. It’s kind to the environment with perks like slashing carbon footprints, cutting down waste, ramping up efficiency, and boosting worker safety, marking it as a stellar alternative to the old-school methods of bonding.

As companies and entire sectors aim to go greener, the popularity of UV Cure Adhesive Glue is set to soar. Looking ahead, we can expect even more advancements in sustainable bonding technologies that promise to be even more efficient and environmentally friendly.

It’s vital for businesses to get on board with sustainable bonding solutions to lessen their environmental impact. By opting for UV Cure Adhesive Glue and other green alternatives, industries not only contribute to a more sustainable planet but also ensure their products remain top-notch and their manufacturing processes streamlined. Embracing these innovations is a smart move towards a greener and more sustainable future.

For more about choosing the environmental benefits of using UV cure adhesive glue for plastic to plastic instead of traditional methods, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.