UV Cure Epoxy Adhesive Incomplete Curing Solutions

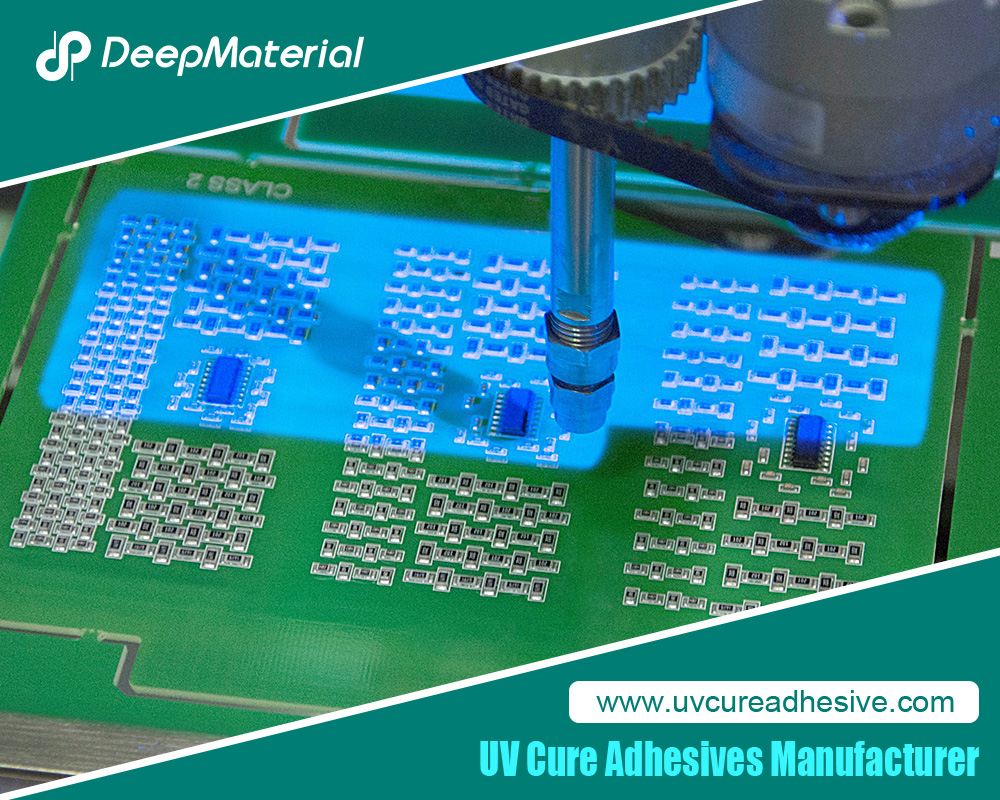

UV cure epoxy adhesives have revolutionized bonding in industries like electronics, optics, medical devices, and automotive manufacturing. These adhesives offer rapid curing under ultraviolet (UV) light, providing strong, durable bonds with minimal heat or mixing required. However, incomplete curing—where the adhesive remains tacky, soft, or fails to achieve full mechanical properties—poses significant challenges. This can lead to bond failures, reduced product lifespan, and increased production costs.

Incomplete curing affects up to 20-30% of UV adhesive applications in high-volume settings, according to industry reports. Causes range from equipment mismatches to environmental factors, but solutions exist to address them systematically. This article explores comprehensive strategies to resolve incomplete curing, drawing on material science, process engineering, and real-world insights. By implementing these solutions, manufacturers can achieve consistent 95-99% cure conversion rates, ensuring bonds with shear strengths exceeding 25 MPa and glass transition temperatures (Tg) above 100°C.

We’ll cover common causes, targeted fixes, advanced technologies, case studies, and best practices, providing a roadmap for troubleshooting and optimization. Whether you’re dealing with surface tackiness or deep-section undercure, the following 2000-word guide equips you with actionable solutions.

Understanding Incomplete Curing

Incomplete curing occurs when the photoinitiated polymerization of epoxy resins fails to reach completion. UV epoxies contain photoinitiators that absorb UV photons (typically 320-405 nm) to generate cations or radicals, initiating ring-opening reactions. Full cure requires sufficient energy to crosslink 90-99% of monomers, forming a rigid network.

Symptoms include:

- Tacky or gummy surfaces.

- Low hardness (e.g., <70 Shore D).

- Reduced adhesion (lap shear <15 MPa).

- Brittleness or cracking under stress.

Diagnostic tools like Fourier Transform Infrared Spectroscopy (FTIR) monitor epoxy peak reduction at 910 cm⁻¹, while Differential Scanning Calorimetry (DSC) quantifies residual exotherm (<10 J/g for full cure). Understanding these metrics is crucial for selecting solutions.

Common Causes and Targeted Solutions

Cause 1: Insufficient UV Light Exposure

One primary issue is inadequate overall UV dose, often due to short exposure times or low lamp output. For instance, UV cure epoxy adhesives requiring 3000 mJ/cm² may only receive 1500 mJ/cm² in rushed processes.

Solutions:

- Extend Exposure Time: Adjust based on adhesive thickness and formulation. For 1 mm layers, increase from 10 to 30 seconds under 500 mW/cm² intensity. Use programmable timers on conveyor systems.

- Monitor Dose with Radiometers: Employ devices like the EIT Power Puck to measure cumulative energy at the bondline. Calibrate weekly to ensure >90% of required dose.

- Upgrade to High-Output Systems: Switch to LED flood lamps (e.g., 10 W/cm²) for consistent delivery, reducing variability from aging mercury bulbs.

In a PCB assembly line, extending exposure by 20% resolved 80% of tacky bonds.

Cause 2: Wavelength Mismatch

Photoinitiators have specific absorption spectra; a mismatch (e.g., 365 nm adhesive under 405 nm light) prevents activation.

Solutions:

- Match Spectra: Review datasheets and use multi-wavelength LEDs (365/395/405 nm arrays) for versatility. Test with small batches to confirm cure.

- Spectral Analysis: Use UV spectrometers to verify lamp output aligns with initiator peaks (e.g., Irgacure 907 at 365 nm).

- Formulation Adjustment: Collaborate with suppliers for custom initiators matching existing equipment.

A medical device manufacturer fixed chronic undercure by adopting tunable LEDs, boosting yield by 15%.

Cause 3: Insufficient UV Intensity

Low intensity fails to penetrate thick or pigmented adhesives, causing gradient curing.

Solutions:

- Boost Intensity: Opt for systems like Uvitron’s high-power units (>1000 mW/cm²). Position lamps closer (5-10 cm) while monitoring heat.

- Lamp Maintenance: Replace bulbs at 70% output decline; clean reflectors quarterly to prevent dust attenuation.

- Intensity Mapping: Use software to simulate and adjust for part geometry, ensuring uniform >200 mW/cm² across surfaces.

Automotive sensor potting improved from 70% to 98% cure with intensity upgrades.

Cause 4: Shadows and Uneven Exposure

Opaque substrates or complex geometries block light, leaving shadowed areas uncured.

Solutions:

- Multi-Angle Irradiation: Employ rotating fixtures or robotic arms with fiber-optic guides for 360° coverage.

- Dual-Cure Formulations: Use hybrid epoxies (UV + thermal/moisture) that continue curing post-UV. Products like Epoxies Etc.’s 60-7170 cure shadows up to 1 inch deep without ovens.

- Transparent Fixtures: Design jigs from quartz or acrylic to transmit UV.

In aerospace composites, dual-cure reduced rework by 40%.

Cause 5: Short Curing Time

Rushing exposure prevents full polymerization, especially in filled systems.

Solutions:

- Optimize Time via DOE: Conduct Design of Experiments varying time, intensity, and thickness to find minima (e.g., 20 s at 500 mW/cm²).

- Automated Controls: Integrate PLCs with sensors to halt lines if time thresholds aren’t met.

- Post-Cure Steps: Add low-heat bakes (60°C for 10 min) for residual cure.

Electronics firms report 25% strength gains from time adjustments.

Cause 6: Oxygen Inhibition

Oxygen quenches surface reactions, causing tackiness in thin films. Solutions:

- Inert Atmosphere: Purge with nitrogen during cure to <1% oxygen.

- Oxygen-Scavenging Additives: Incorporate phosphites or amines in formulations for tack-free surfaces.

- Thicker Applications: Apply >100 μm layers where possible, as bulk resists inhibition.

Optical lens bonding achieved haze-free results with N2 blanketing.

Cause 7: Material Thickness and Limited Depth

UV attenuates per Beer-Lambert law, limiting cure to 1-5 mm.

Solutions:

- Reduce Thickness: Dispense precisely (e.g., 0.5 mm) via robotic nozzles.

- Sensitizers: Add compounds like anthraquinone to enhance penetration.

- Layered Curing: Apply and cure in stages for deep pots.

Potting compounds now cure 25 mm with advanced sensitizers.

Cause 8: Contamination and Surface Issues

Dirt, oils, or moisture inhibit wetting and reaction.

Solutions:

- Surface Preparation: Plasma treat or IPA wipe substrates for <20° contact angle.

- Clean Environments: Use Class 1000 cleanrooms; store adhesives in desiccators.

- Contaminant Testing: XPS analysis to detect residues pre-assembly.

Yield improvements of 30% in clean processes.

Cause 9: Environmental Factors (Temperature, Humidity)

Low temps slow kinetics; high humidity hydrolyzes.

Solutions:

- Control Climate: Maintain 20-25°C and <50% RH in cure zones.

- Pre-Heat Substrates: Warm to 30°C for better flow and reaction.

- Humidity-Resistant Formulas: Select low-water-absorption epoxies.

Winter production stabilized with HVAC upgrades.

Cause 10: Overexposure and Degradation

Excess UV causes brittleness or yellowing.

Solutions:

- Dose Control: Use feedback loops to cap at 150% required.

- Cooling Systems: Fans or water-cooled lamps prevent >50°C rises.

- UV Stabilizers: Add HALS (hindered amine light stabilizers) to formulations.

Controlled exposure extends service life 2x.

Advanced Techniques for Incomplete Curing

Emerging solutions include:

- Smart Adhesives: Embedded indicators change color at full cure.

- AI-Optimized Processes: Machine learning predicts dose from variables like thickness and humidity.

- Visible Light Curing: Shift to 400-450 nm for safer, deeper penetration.

- Nanofillers: Graphene enhances light scattering for uniform cure.

These boost efficiency by 20-50% in R&D trials.

Case Studies

Case 1: Electronics Potting (Uvitron Insight)

A smartphone assembler faced tacky encapsulants. Analysis showed intensity drop from aged lamps. Solution: High-intensity LEDs and uniform exposure via rotators. Result: 99% cure, zero field failures.

Case 2: Medical Catheters (Epoxies Etc.)

Shadows in tubing caused delamination. Adopted dual-cure resin 60-7170; initial UV triggered dark cure. Depth reached 15 mm, eliminating ovens.

Case 3: Optical Assemblies (Incure)

Wavelength mismatch left hazy bonds. Matched 365 nm lamps per guidelines; calibration resolved issues, improving clarity 40%.

Best Practices for Prevention

- Equipment Calibration: Quarterly radiometer checks.

- Material Validation: Batch testing via DSC/FTIR.

- Training Programs: Operator education on causes/solutions.

- Process Audits: ISO 9001-compliant DOE for optimization.

- Supplier Partnerships: Custom formulations for specific needs.

Table: Quick Solution Checklist

| Cause | Solution | Expected Improvement |

| Insufficient Exposure | Extend time, monitor dose | 20-30% yield increase |

| Wavelength Mismatch | Spectral matching | Full cure in 95% cases |

| Shadows | Dual-cure hybrids | Eliminate secondary steps |

| Oxygen Inhibition | Inert purge | Tack-free surfaces |

Conclusion

Incomplete curing in UV cure epoxy adhesives is a solvable challenge with targeted interventions. From matching wavelengths and boosting intensity to adopting dual-cure technologies, these solutions ensure robust bonds in demanding applications. By integrating diagnostics, process controls, and advanced materials, manufacturers can minimize failures and maximize efficiency.

As of 2025, innovations like AI-driven curing promise even greater reliability. Implementing the strategies here not only fixes current issues but prevents future ones, turning potential pitfalls into production strengths. For optimal results, start with a root-cause analysis and scale solutions iteratively.

For more about UV cure epoxy adhesive incomplete curing solutions, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.